详情

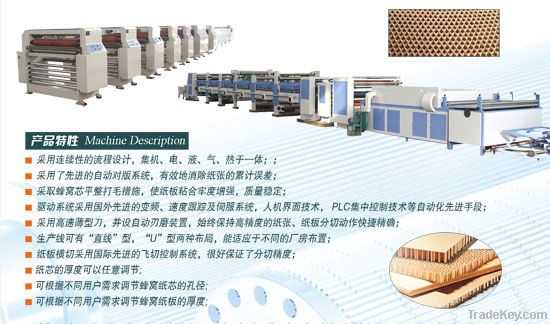

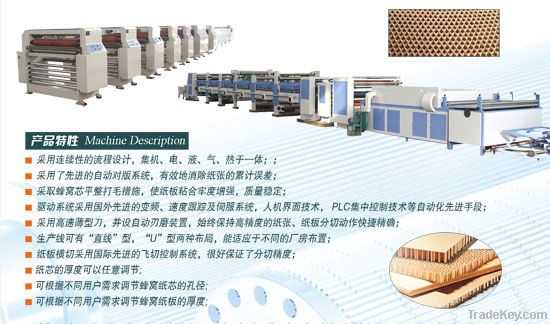

Technical Features:

1. Can achieve continuous production of

honeycomb core paper with infinite length and any needed

width.

New systematic process design,

horizontal glueing, vertical continuous cutting, transferred

position and combined into infinite honeycomb paper core,

achieving the continuity and automation of whole process from

paper feeding to cardboard forming. Omit the stacking of paper,

core paper compaction, core paper cutting and other complex,

cumbersome processes, saving the equipments for the related

processes. According to customer demands, it can cut out of any

width of the paper core.

2. Thickness of Paper core can

be adjusted arbitrarily.

The production line uses

"scissors type" method of roll cut to cut paper, by adjusting the

spacing of the cutter to change the paper width (the thickness of

paper core). According to the different needs of customers, paper

core thickness can be adjusted within the range of

****0mm.

3. Pore diameter of honeycomb

paper core series

The pore size of honeycomb paper

core is the one of the main factors of impacting the honeycomb

paper core strength, different pore size, the intensity changes

exponentially. According to

customer’s different requirements for honeycomb paper core

strength, the glue roller with different diameter have been

designed, By replacing the glue roller, can produce the honeycomb

paper core the users needed.

4.“Super Wide”type honeycomb paperboard:

Because of the honeycomb paper

core produced by oue equipments is continuous, user can meet

himself demand for the length specification of honeycomb paper to

cut, so we can manufacture the related width honeycomb paperboard

production line for customers’ demand width to produce the

“SuperWide” type honeycomb paperboard. Currently the production

line can meet the maximum width of 2.2 meters.

5. Adjust the thickness of honeycomb according to different

users’ needs

According to the different

thickness of cardboard for users’ needs, the production line

equipments have a greater range of adjustment design, by

adjusting the hydraulic system to control the movements of the

conveyor belt to produce a variety of different sizes, different

thickness of honeycomb paperboard, to meet customer needs.

6. According to the different needs of users, cutting different

lengths of honeycomb

The production line select and

use the German SIEMENS flying cutting system, centralized control

by the man-machine interface, adopt the encoder to get speed

track, without downtime, uses only have to data directly

through the man-machine interface, to get the length of the

honeycomb they needed any time and the cutting error is very

small (± 1.5mm).