离岸价格

获取最新报价40 ~ 48 USD / Metric Ton

|2000 Metric Ton Minimum Order

国家:

Cameroon

型号:

-

离岸价格:

40 ~ 48 USD / Metric Ton 获取最新报价

位置:

DRC congo and Zambia

最小订单价格:

40 per Metric Ton

最小订单:

2000 Metric Ton

包装细节:

Standard export packaging in jumbo bags

交货时间:

35 to 45

供应能力:

20000 Metric Ton per Month

付款方式:

T/T, D/A, D/P, Western Union, Money Gram

產品組 :

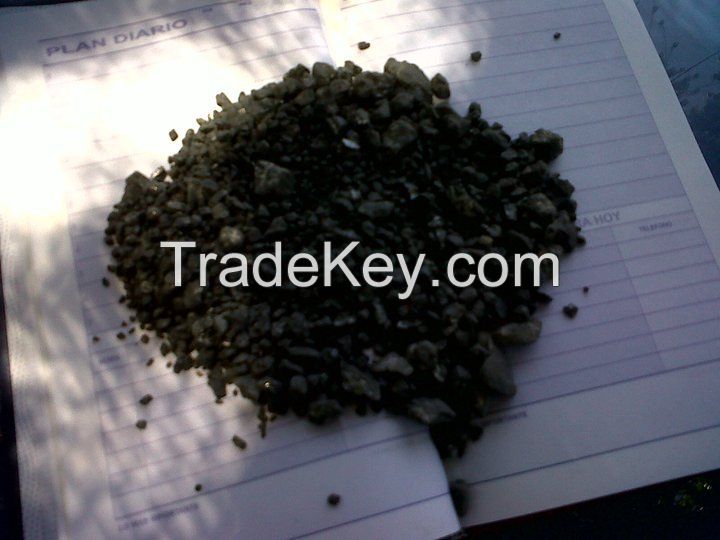

Coltan (short for columbitetantalite's and known industrially as

tantalite) is a dull black metallic ore from which are extracted

the elements niobium and tantalum. The niobium-dominant mineral in

coltan is columbite (after niobium's original American name

columbium), and the tantalum-dominant mineral is tantalite.

Tantalum from coltan is used to manufacture tantalum capacitors

which are used for portable telephones, personal computers,

automotive electronics, and cameras. Coltan mining has financed

serious conflicts

About coltan

Early history

Coltan was discovered in ***2, one year after niobium. In ***1,

Charles Hatchett (********7), an English chemist, analyzed a

specimen of an unknown mineral from the collection of the British

Museum in London. This was a heavy black mineral obtained from the

collection of the first governor of Connecticut, John Winthrop, who

was an alchemist, manufacturing chemist, physician, and rock

collector. The mineral, later called columbite, was found near New

London, Connecticut. Charles Hatchett determined that this mineral

contained a 'new earth', which implied a new element had been

found. He named this element columbium apparently in reference to

its source being America.

The names columbium and niobium were both used to identify this

element for almost another century, with columbium being preferred

in the Americas. It was not until ***9 that the International Union

of Pure and Applied Chemistry (IUPAC) officially adopted niobium as

the name for this element. Old habits die slowly, and some

metallurgists continue to use the term columbium to this day.

Typical market specifications

Coltan on the international market generally contains a minimum of

*0% Ta2O5, while lower grade material with a minimum of *0% Ta2O5

may also be of interest. The commercial payable value is based on

the Ta2O5 content alone, any Nb2O5 is generally ignored.

Should material contain mainly Nb2O5 and only little Ta2O5, then it

would be sold as columbite and should contain a minimum of *0%

Nb2O5. The payable value is based on the Nb2O5+Ta2O5 content

payable entirely as Nb2O5; the Ta2O5 content is not paid a higher

rate.

Other Requirements

Coltan and niobium raw materials often contain somewhat elevated

levels of naturally occurring and , usually high enough for them to

be classified as radioactive for handling and transport. Such raw

materials are then also known as Naturally Occurring Radioactive

Materials (NORM).

It is incumbent on any producer or trader to also analyze for Th

and U in order to demonstrate whether the material is radioactive

or not. This is reflected in the T.I.C.'s Transport Policy. As a

guide, these elements are of concern for the purpose of mining and

handling at levels above 1 Bq/g, a level obtained from e.g. 0.**3%

ThO2 plus 0.***8% U3O8, whereas for transport alone the levels of

concern are an order of magnitude higher, i.e.*0 Bq/g or 0.*3% ThO2

plus 0.**8% U3O8.

Production of raw materials

Extraction or production of Coltan raw materials of all kinds is

widespread, whether by primary industrial mining, artisanal mining,

as a secondary mineral or as a byproduct. Brazil is currently the

major producer. Significant quantities are also produced in China,

the DR Congo, Russia and Rwanda. Additional quantities are

produced, some intermittently or at a low level,Processing:

extraction and refining

The extraction and refining of Coltan, including the separation

from niobium in these various tantalum-containing mineral

concentrates, is generally accomplished by treating the ores with a

mixture of hydrofluoric and sulfuric acids at elevated

temperatures. This causes the Coltan and niobium values to dissolve

as complex fluorides, and numerous impurities that were present

also dissolve. Other elements such as silicon, iron, manganese,

titanium, zirconium, , , rare earths, et c. are generally present.

The filtration of the digestion slurry, and further processing via

solvent extraction using methyl isobutyl ketone (MIBK) or liquid

ion exchange using an amine extractant in kerosene, produces highly

purified solutions of Coltan and niobium. Generally, the tantalum

values in solution are converted into potassium tantalum fluoride

(K2TaF7) or tantalum oxide (Ta2O5). The niobium is recovered as

niobium oxide (Nb2O5) via neutralization of the niobium fluoride

complex with ammonia to form the hydroxide, followed by calcination

to the oxide.

There exist alternative methods which are used when they are better

suited to particular local conditions. One used for a

titanium-niobium-tantalum-rare earth mineral concentrate involves

blending the crushed concentrate with coke and passing this through

a chlorination stage which separates out the rare earths and other

elements including most of the . The resulting

titanium-niobium-tantalum oxychloride gas is dropped in temperature

which causes the iron, and alkali metals to precipitate out. The

cleaned titanium-niobium-tantalum oxychloride gas is then cooled to

a liquid and distilled to separate out low-boiling titanium

chloride gas, whereafter the niobium-tantalum oxychloride gas is

further chlorinated to produce NbCl5 and TaCl5. These chlorides are

fractionally distilled and the niobium chloride subsequently

reacted with steam to produce the hydroxide which is calcined to

oxide. The tantalum chloride is reacted with ammonium hydroxide to

produce the oxide.

The primary tantalum chemicals of industrial significance, in

addition to K2TaF7 and Ta2O5, are tantalum chloride (TaCl5),

lithium tantalate (LiTaO3) and tantalum carbide (TaC).

Tantalum metal powder, including the precursor to capacitor grade

powder, is generally produced by the sodium reduction of the

potassium tantalum fluoride in a molten salt system at high

temperature. The metal can also be produced by the carbon or

aluminum reduction of the oxide or the hydrogen or alkaline earth

reduction of tantalum chloride. The choice of process is based on

the specific application and whether the resultant tantalum will be

further consolidated by processing into ingot, sheet, rod, tubing,

wire and other fabricated articles.

The consolidation of metal powder for ingot and processing into

various metallurgical products begins with either vacuum arc

melting or electron beam melting of metal feedstocks, comprised of

powder or high purity scrap where the elements with boiling points

greater than tantalum are not present. Double and triple melt

ingots achieve a very high level of purification with regard to

metallics and interstitials. Ingots are used to produce the various

metallurgical products named earlier. Ingot stock is also used for

the production of such alloys as tantalum**0% tungsten. Ingot and

pure tantalum scrap are used in the production of alloys for land

and air-based turbines.

Use and demand

Coltan is used primarily for the production of tantalum capacitors,

used in many electronic devices. Many sources mention coltan's

importance in the production of mobile phones, but tantalum

capacitors are used in almost every kind of electronic device.

Niobium and tantalum have a wide range of uses, including

refractive lenses for glasses, cameras, phones and printers. They

are also used in semiconductor circuits, and capacitors for small

electronic devices such as hearing aids, pacemakers, and mp3

players, as well as in computer hard drives, automobile

electronics, and surface acoustic wave (SAW) filters for mobile

phones.

Coltan is also used to make high-temperature alloys for jet engines

and air- and land-based turbines. More recently, the

nickel-tantalum superalloys used in jet engines account for *5% of

tantalum consumption, but pending orders for the Airbus and the **7

Dreamliner may increase this proportion, as well as China's

pending order for *2 ****8 airplanes.

COLTAN (Columbite-Tantalite) is a dull metallic ore found in major

quantities in the eastern areas of Congo. When refined, COLTAN

becomes metallic Tantalum, a heat-resistant powder that can hold a

high electrical charge.

Columbite ((Fe, Mn, Mg)(Nb, Ta)2O6 : Iron Manganese Magnesium

Niobium Tantalum Oxide) is the most abundant niobium mineral and is

used in alloys for improved strength. Also known as Niobium, it

also has shown potential superconductive properties and is being

used in studies with other metals for possible breakthroughs in the

manufacturing of superconductive alloys.

The COLTAN

Tantalite ((Fe, Mn)(Ta, Nb)2O6 : Iron Manganese Tantalum Niobium

Oxide) is the most widespread tantalum mineral and makes for an

important ore of the industrially useful metal. Tantalum (Ta) is a

gray, heavy, and extremely hard metal. When pure, it is ductile and

can be drawn into fine wire, which is used as a filament for

evaporating metals such as aluminum. Tantalum is almost completely

immune to chemical reaction at temperatures low temperatures

(sub***0 degrees C), and is reactive only with hydrofluoric acid,

acidic solutions containing the fluoride ion, and free sulfur

trioxide. At higher temperatures, Tantalum becomes much more

reactive though it has a melting point exceeded only by Tungsten

and Rhenium. Tantalum is used to make a variety of alloys with

desirable properties such as extremely high melting points, extreme

strength, good ductility, etc. Tantalum has good gettering ability

at high temperatures, and tantalum oxide films are stable with good

rectifying and dielectric properties.

Tantalum is used mainly in the manufacture of condensers and

micro-electronic technology (chips and processors), cell phones and

nuclear reactors. It is also used in the production of steel

varieties having a high heat tolerances, like those used in the

engines of aircraft. Whereas it was formerly only one secondary

product of the exploitation of Tin, Tantalum became today, under

the terms of its specific characteristics, a very required

element.

The principal modern extraction takes place in many places, in the

Wodgina mine, where the annual production of Ta2O5 reaches

approximately **0,**0 tons. In ***0, the ore typically sold on

world markets for approximately $**0.*0 USD per kilogram. The

recent technology boom and low availability of COLTAN caused a

substantial increase in the price to almost $**0 USD per kilogram

at one point, as supply struggled to meet the demands of companies

such as Nokia and Sony.

Little information is currently available regarding the amount of

radiation absorbed by the body via the inhalation of dust during

the treatment and extraction of COLTAN. It is known however that

the radioactivity is found almost entirely in the residue of the

ore, and not in its finished products (GSM, computers, etc.).

Coltan

Coltan (short for columbitetantalite's and known industrially as

tantalite) is a dull black metallic ore from which are extracted

the elements niobium and tantalum. The niobium-dominant mineral in

coltan is columbite (after niobium's original American name

columbium), and the tantalum-dominant mineral is tantalite.

Tantalum from coltan is used to manufacture tantalum capacitors

which are used for portable telephones, personal computers,

automotive electronics, and cameras. Coltan mining has financed

serious conflicts

About coltan

Early history

Coltan was discovered in ***2, one year after niobium. In ***1,

Charles Hatchett (********7), an English chemist, analyzed a

specimen of an unknown mineral from the collection of the British

Museum in London. This was a heavy black mineral obtained from the

collection of the first governor of Connecticut, John Winthrop, who

was an alchemist, manufacturing chemist, physician, and rock

collector. The mineral, later called columbite, was found near New

London, Connecticut. Charles Hatchett determined that this mineral

contained a 'new earth', which implied a new element had been

found. He named this element columbium apparently in reference to

its source being America.

The names columbium and niobium were both used to identify this

element for almost another century, with columbium being preferred

in the Americas. It was not until ***9 that the International Union

of Pure and Applied Chemistry (IUPAC) officially adopted niobium as

the name for this element. Old habits die slowly, and some

metallurgists continue to use the term columbium to this day.

Typical market specifications

Coltan on the international market generally contains a minimum of

*0% Ta2O5, while lower grade material with a minimum of *0% Ta2O5

may also be of interest. The commercial payable value is based on

the Ta2O5 content alone, any Nb2O5 is generally ignored.

Should material contain mainly Nb2O5 and only little Ta2O5, then it

would be sold as columbite and should contain a minimum of *0%

Nb2O5. The payable value is based on the Nb2O5+Ta2O5 content

payable entirely as Nb2O5; the Ta2O5 content is not paid a higher

rate.

Other Requirements

Coltan and niobium raw materials often contain somewhat elevated

levels of naturally occurring and , usually high enough for them to

be classified as radioactive for handling and transport. Such raw

materials are then also known as Naturally Occurring Radioactive

Materials (NORM).

It is incumbent on any producer or trader to also analyze for Th

and U in order to demonstrate whether the material is radioactive

or not. This is reflected in the T.I.C.'s Transport Policy. As a

guide, these elements are of concern for the purpose of mining and

handling at levels above 1 Bq/g, a level obtained from e.g. 0.**3%

ThO2 plus 0.***8% U3O8, whereas for transport alone the levels of

concern are an order of magnitude higher, i.e.*0 Bq/g or 0.*3% ThO2

plus 0.**8% U3O8.

Production of raw materials

Extraction or production of Coltan raw materials of all kinds is

widespread, whether by primary industrial mining, artisanal mining,

as a secondary mineral or as a byproduct. Brazil is currently the

major producer. Significant quantities are also produced in China,

the DR Congo, Russia and Rwanda. Additional quantities are

produced, some intermittently or at a low level,Processing:

extraction and refining

The extraction and refining of Coltan, including the separation

from niobium in these various tantalum-containing mineral

concentrates, is generally accomplished by treating the ores with a

mixture of hydrofluoric and sulfuric acids at elevated

temperatures. This causes the Coltan and niobium values to dissolve

as complex fluorides, and numerous impurities that were present

also dissolve. Other elements such as silicon, iron, manganese,

titanium, zirconium, , , rare earths, et c. are generally present.

The filtration of the digestion slurry, and further processing via

solvent extraction using methyl isobutyl ketone (MIBK) or liquid

ion exchange using an amine extractant in kerosene, produces highly

purified solutions of Coltan and niobium. Generally, the tantalum

values in solution are converted into potassium tantalum fluoride

(K2TaF7) or tantalum oxide (Ta2O5). The niobium is recovered as

niobium oxide (Nb2O5) via neutralization of the niobium fluoride

complex with ammonia to form the hydroxide, followed by calcination

to the oxide.

There exist alternative methods which are used when they are better

suited to particular local conditions. One used for a

titanium-niobium-tantalum-rare earth mineral concentrate involves

blending the crushed concentrate with coke and passing this through

a chlorination stage which separates out the rare earths and other

elements including most of the . The resulting

titanium-niobium-tantalum oxychloride gas is dropped in temperature

which causes the iron, and alkali metals to precipitate out. The

cleaned titanium-niobium-tantalum oxychloride gas is then cooled to

a liquid and distilled to separate out low-boiling titanium

chloride gas, whereafter the niobium-tantalum oxychloride gas is

further chlorinated to produce NbCl5 and TaCl5. These chlorides are

fractionally distilled and the niobium chloride subsequently

reacted with steam to produce the hydroxide which is calcined to

oxide. The tantalum chloride is reacted with ammonium hydroxide to

produce the oxide.

The primary tantalum chemicals of industrial significance, in

addition to K2TaF7 and Ta2O5, are tantalum chloride (TaCl5),

lithium tantalate (LiTaO3) and tantalum carbide (TaC).

Tantalum metal powder, including the precursor to capacitor grade

powder, is generally produced by the sodium reduction of the

potassium tantalum fluoride in a molten salt system at high

temperature. The metal can also be produced by the carbon or

aluminum reduction of the oxide or the hydrogen or alkaline earth

reduction of tantalum chloride. The choice of process is based on

the specific application and whether the resultant tantalum will be

further consolidated by processing into ingot, sheet, rod, tubing,

wire and other fabricated articles.

The consolidation of metal powder for ingot and processing into

various metallurgical products begins with either vacuum arc

melting or electron beam melting of metal feedstocks, comprised of

powder or high purity scrap where the elements with boiling points

greater than tantalum are not present. Double and triple melt

ingots achieve a very high level of purification with regard to

metallics and interstitials. Ingots are used to produce the various

metallurgical products named earlier. Ingot stock is also used for

the production of such alloys as tantalum**0% tungsten. Ingot and

pure tantalum scrap are used in the production of alloys for land

and air-based turbines.

Use and demand

Coltan is used primarily for the production of tantalum capacitors,

used in many electronic devices. Many sources mention coltan's

importance in the production of mobile phones, but tantalum

capacitors are used in almost every kind of electronic device.

Niobium and tantalum have a wide range of uses, including

refractive lenses for glasses, cameras, phones and printers. They

are also used in semiconductor circuits, and capacitors for small

electronic devices such as hearing aids, pacemakers, and mp3

players, as well as in computer hard drives, automobile

electronics, and surface acoustic wave (SAW) filters for mobile

phones.

Coltan is also used to make high-temperature alloys for jet engines

and air- and land-based turbines. More recently, the

nickel-tantalum superalloys used in jet engines account for *5% of

tantalum consumption, but pending orders for the Airbus and the **7

Dreamliner may increase this proportion, as well as China's

pending order for *2 ****8 airplanes.

COLTAN (Columbite-Tantalite) is a dull metallic ore found in major

quantities in the eastern areas of Congo. When refined, COLTAN

becomes metallic Tantalum, a heat-resistant powder that can hold a

high electrical charge.

Columbite ((Fe, Mn, Mg)(Nb, Ta)2O6 : Iron Manganese Magnesium

Niobium Tantalum Oxide) is the most abundant niobium mineral and is

used in alloys for improved strength. Also known as Niobium, it

also has shown potential superconductive properties and is being

used in studies with other metals for possible breakthroughs in the

manufacturing of superconductive alloys.

The COLTAN

Tantalite ((Fe, Mn)(Ta, Nb)2O6 : Iron Manganese Tantalum Niobium

Oxide) is the most widespread tantalum mineral and makes for an

important ore of the industrially useful metal. Tantalum (Ta) is a

gray, heavy, and extremely hard metal. When pure, it is ductile and

can be drawn into fine wire, which is used as a filament for

evaporating metals such as aluminum. Tantalum is almost completely

immune to chemical reaction at temperatures low temperatures

(sub***0 degrees C), and is reactive only with hydrofluoric acid,

acidic solutions containing the fluoride ion, and free sulfur

trioxide. At higher temperatures, Tantalum becomes much more

reactive though it has a melting point exceeded only by Tungsten

and Rhenium. Tantalum is used to make a variety of alloys with

desirable properties such as extremely high melting points, extreme

strength, good ductility, etc. Tantalum has good gettering ability

at high temperatures, and tantalum oxide films are stable with good

rectifying and dielectric properties.

Tantalum is used mainly in the manufacture of condensers and

micro-electronic technology (chips and processors), cell phones and

nuclear reactors. It is also used in the production of steel

varieties having a high heat tolerances, like those used in the

engines of aircraft. Whereas it was formerly only one secondary

product of the exploitation of Tin, Tantalum became today, under

the terms of its specific characteristics, a very required

element.

The principal modern extraction takes place in many places, in the

Wodgina mine, where the annual production of Ta2O5 reaches

approximately **0,**0 tons. In ***0, the ore typically sold on

world markets for approximately $**0.*0 USD per kilogram. The

recent technology boom and low availability of COLTAN caused a

substantial increase in the price to almost $**0 USD per kilogram

at one point, as supply struggled to meet the demands of companies

such as Nokia and Sony.

Little information is currently available regarding the amount of

radiation absorbed by the body via the inhalation of dust during

the treatment and extraction of COLTAN. It is known however that

the radioactivity is found almost entirely in the residue of the

ore, and not in its finished products (GSM, computers,

etc.).

We supply high-grade ColtanTantalite Ore (Ta₂O₅ content

***0%), sourced directly from the Democratic Republic of Congo

(DRC) and Zambia, suitable for industrial applications in tantalum

and niobium production.

Specifications & Chemical Breakdown (Typical):

Ta₂O₅: ***0%

Nb₂O₅: ***5%

Fe₂O₃: **2%

TiO₂: *8%

SnO₂: *5%

SiO₂ + other trace elements: Balance

Condition: Free from radioactive and hazardous

materials

Inspection: SGS or equivalent at loading port

Commercial Terms:

Quantity Available: *0,**0 MT (monthly supply

capacity)

Trial Shipment: 2,***3,**0 MT

Price: USD $*0/lb per MT (CIF basis)

Origin: DRC & Zambia

Port of Loading: Dar es Salaam, Tanzania

Delivery Estimate:

Asia: ***0 days

Europe: ***5 days

North America: ***0 days

South America: ***5 days

Packaging & Packing:

Standard export packaging in jumbo bags (*2 MT

each)

Bags securely strapped and palletized (if

required)

Seaworthy packaging to buyers specifications

Container Loading Capacity:

*0 container: ~***2 MT

*0 HC container: ~***8 MT

We ensure reliable supply, SGS-certified quality and quantity, and

secure shipping under CIF terms.

| 国家: | Cameroon |

| 型号: | - |

| 离岸价格: | 40 ~ 48 / Metric Ton 获取最新报价 |

| 位置: | DRC congo and Zambia |

| 最小订单价格: | 40 per Metric Ton |

| 最小订单: | 2000 Metric Ton |

| 包装细节: | Standard export packaging in jumbo bags |

| 交货时间: | 35 to 45 |

| 供应能力: | 20000 Metric Ton per Month |

| 付款方式: | T/T, D/A, D/P, Western Union, Money Gram |

| 產品組 : | Coltan (Tantalite) Ore |