Usage and Application of Diesel Jaw Crusher

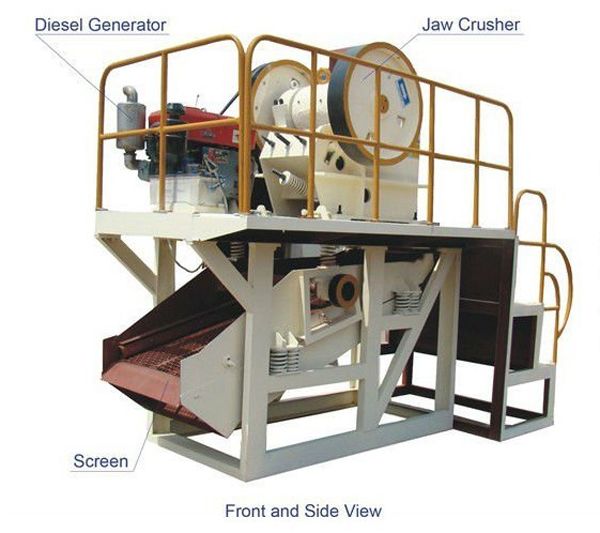

This diesel powered jaw crusher is mainly used in some places where don't have enough electricity or without electricity. The diesel engine has the highest thermal efficiency of any standard internal or external combustion engine due to its very high compression ratio. It can do middle or fine crushing for every kind of rocks and stones.

This kind of crusher is in compact structure, easy usage and simple operation.

Jaw Crusher is the most universal international Crusher with the advantages of great crushing ratio, even granularity, simple structure , convenient maintenance, widely used in mining, metall-urgical industry, building material, highway, railway, and chemical industry; and it is mainly used to primarily crush many kinds of mining stones, and the largest compression resistance of the material to be crushed is **0MPa.

Working Principle of Diesel

Jaw Crusher

The structure of jaw crusher: main frame, eccentric shaft, a large belt pulley, fly wheel, swing jaw, side guard plate, toggle plate, Rear bracket, adjust gap screw, reset spring, and fixed jaw and swing jaw board etc., and the toggle plate also plays a role of protection.

The diesel

engine transmits

power through belt and

belt pulley,

drives the swing jaw surround the eccentric

shaft do

periodicotion. The angle between toggle plate and swing jaw increases when swing jaw moves up., which makes the moving jaw get closes to the fixed jaw. At the same time the material is squeezed, rubbing, grinding and other multiple broken. The angle of Jaw Crusher between toggle plate and swing jaw decreases when swing jaw moves down, the moving jaw of Jaw Crusher moves away from fixed jaw by the pulling of rod and spring, the products after crushing will be discharged from the outlet of Jaw Crusher.

Main Technical Parameters of Diesel Jaw crusher

| type | Feed opening size(mm) | Max. feed size(mm) | Discharge adjustment range(mm) | Capacity(m³/h)m³/h) | Motor(kw) | Rotating speed of mainshaft(r/min) | Weight (kg) | Overall dimension(L*W*H)(mm) |

| PEF**0***0 | **0***0 | **5 | ****0 | **3 | 7.5 | **5 | **0 | **2***5***3 |

| PEF**0***0 | **0***0 | **5 | ****0 | **8 | *1 | **5 | **0 | ***6****0****0 |

| PEF**0***0 | **0***0 | **0 | ****0 | ***0 | *8.5 | **0 | ***0 | ***8****2****2 |

| PEF**0***0 | **0***0 | **0 | ****0 | ****0 | *0 | **5 | ***0 | ***0****2****2 |

| PEF**0***0 | **0***0 | **0 | ****5 | ****0 | *7 | **0 | ***0 | ***0****6****8 |

| PEF**0***0 | **0***0 | **5 | *****0 | ****8 | *5 | **5 | ****0 | ***0****0****5 |

| PEF**0***0 | **0***0 | **0 | *****0 | *****0 | *5 | **5 | ****0 | ***2****8****0 |

| PEF**0****0 | **0****0 | **0 | *****0 | *****0 | *0 | **0 | ****0 | ***0****0****0 |

| PEF**0****0 | **0****0 | **0 | ******0 | ******0 | **0 | **0 | ****0 | ***0****0****0 |

| PEF***0****0 | ***0****0 | **0 | ******5 | ******0 | **0 | **0 | ****0 | ***0****6****0 |

| PEF***0****0 | ***0****0 | ***0 | ******0 | ******0 | **0 | **0 | *****0 | ***0****0****0 |

| PEX**0***0 | **0***0 | **5 | ****0 | ***5 | *5 | **0 | ***0 | ***0****0****0 |

| PEX**0****0 | **0****0 | **0 | ****5 | ****2 | *0 | **0 | ***0 | ***0****2****0 |

| PEX**0****0 | **0****0 | **0 | ****0 | ****8 | *7 | **0 | ***0 | ***0****2****0 |

| PEX**0****0 | **0****0 | **0 | ****0 | ****5 | *5 | **0 | ****0 | ***0****0****7 |

Warmth Warning:

Jaw crusher wearing parts

Jaw crusher wearing parts are the important part of jaw crusher, need to be replaced within a certain period. The wearing parts can be divided into side guard plate(also called side fender), jaw plates(include movable jaw plate and fixed jaw plate), toggle plate, triangular belt(also called v-belt)etc.

Jaw crusher side guard plate

Jaw crusher side guard plates between the fixed jaw plate and movable jaw plate are the high manganese steel castings of high quality. They are mainly used to protect the jaw crusher frame wall.

Jaw crusher teeth plate(or called jaw plate)

Jaw crusher teeth plates (movable jaw plate and fixed jaw plate) are all high manganese steel castings of high quality. To prolong its service life, the shape of jaw crusher teeth plate is designed into upper and lower symmetry. When one end is worn, the other end can be used. Swing tooth plate and fixed tooth plate are the main qualification for stone crushing. The swing tooth plate is installed on the moving jaw to protect the moving jaw.

Jaw crusher toggle plate

Toggle plate is iron casting with precise calculation. It is not only the power transmission component, but also safety part of the crusher. When some materials can’t be crushed fall into the crusher and make the machine more than normal load, the toggle plate will be broken immediately, and the crusher will stop working, so that to avoid the damage of the machine. Between the toggle plate and elbow pad there is little friction under normal use in the rolling contact way, just need to coat with a layer of grease on the contact surface. The whole unit is used to adjust the discharging mouth size and compensate for the wear between jaw plates, toggle plate and the elbow pad.

Jaw crusher triangular belt (V-belt)

Triangular belt is used in the motor drive to connect the motor pulley and the sheave, and drive the eccentric shaft to make the moving jaw on the set path for reciprocating motion.

Material and service life of jaw crusher wearing parts Henan Libo Mining Machinery provide

|

Name |

Material |

Service life |

|

Movable jaw plate |

high manganese steel |

about 4 months |

|

Fixed jaw plate |

high manganese steel |

about 4 months |

|

Toggle plate |

cast iron |

about 2 months |

| 国家: | China |

| 型号: | - |

| 离岸价格: | 10000 ~ 15000 / Set 获取最新报价 |

| 位置: | - |

| 最小订单价格: | 10000 per Set |

| 最小订单: | 1 Set |

| 包装细节: | export standard |

| 交货时间: | 15-30 days |

| 供应能力: | 50 Set per Month |

| 付款方式: | T/T, L/C |

| 產品組 : | crushing plants |