详情

0.7mw 1.4mw 2.8mw 7mw 13 Bar Coal Fired Hot Water Boiler

for Central Heating Industry

Coal fired hot water boiler

Thermal Power : 0.7mw/h, 1.4mw/h, 2.8mw/h, 4.2mw/h,

5.6mw/h,7mw/h,10.5mw/h,14mw/h

CDZL Boiler is Single drum, automatic fuel feeding, automatic water

feeding, automatic ashremove

Fuel for CDZL hot water boiler : Coal, biomass, rice husk, wood

pellet, staw pellet, saw dust, wood waste, peanut shell

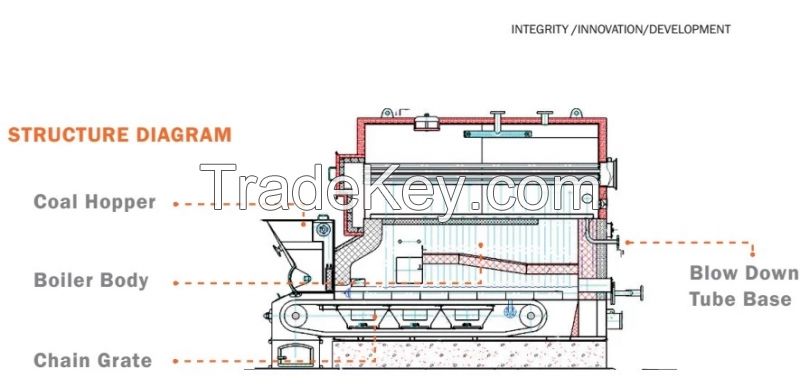

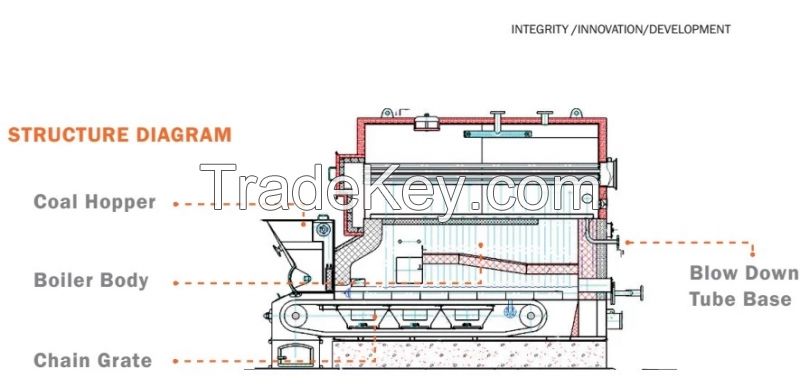

New type DZL(H) hot water boiler is the single drum longitudinal

type water and fire tube shell water boiler,the burning equipment

is the moving grate.The furnace wall take heat resistance as the

whole trumpet bell and ramming to be the new process,the boiler

host outside is the solid figure guard board shell.

This hot water boiler adopt chain grate,suitable for molding pellet

fuel,can add a small amount of wood,wood block,also can burn with

coal.

This hot water heating boiler adopt the newest achievements in

scientific research, such as:Arched Tube plate, thread smoke tube

etc, solve the tube plate crack of shell type boiler, Water wall

tube burst, low efficiency, insufficient of power,Poor pf coal type

adaptability etc.

Structure of hot water boiler

Details Inside the Boiler:

Details Inside the Boiler:

Chain Grate: Strong, high temperature resistant, chain grate bar is

close connect, the coal or other fuel can not draw down

Smoke Tube and water tube: Enough smoke tube and water tube, make

the boiler high efficiency. the smoke tube can be cleaned

easily.

The boiler have man hold and hand hole, which make the boiler easy

to maintain and repaire.

Welding: Our boiler use the advanced seamless welding

technology.

Design: the most suitable design, make the boiler easy to install

and operate.

Boiler Features of automatic control and fault

protection

1, water supply automatic control:

When the system goes to work and works normally, start the feed

water pump, the water pump works, the water level differential

pressure transmitter detects the water level signal, and keeps the

water level of the drum stable.The water level gauge shows the

boiler water level.

2. Manual control: manual control of water pump can also be carried

out by touching the button manually on the control panel.

Fault alarm and protection

The control system can monitor the current working condition of the

boiler in real time, and carry out real time and comprehensive

intelligent fault identification and processing.The control system

can diagnose and deal with the following faults in real time:

1, pot water shortage protection: boiler water pump failure or

other reasons for extremely low water level fault, the control

system immediately shut down the power supply, into the chain, and

sound and light alarm, the screen shows the water level is very

low.After the fault is eliminated, press the reset button to remove

the chain.

2, boiler water level is too high: when the water level in the pot

is higher than the upper warning level, the sound and light alarm

will be given."The water level in the pot is ultra high limit"

prompts, and the display prompts drainage.Automatic recovery after

fault elimination, stop the pump and keep the furnace.

3. Pump motor overload: heat relay action when the pump motor

overflows, cut off the power supply of the pump motor and stop the

pump, which is realized by hardware.

4, power failure: when the power failure occurs, the control system

immediately shut down the power supply of all equipment in the

cabinet of power failure.When the power is restored, the cabinet is

automatically off duty. It is necessary to restart the machine and

start all the equipment to ensure the safety of the equipment.

Feeding System Introduction:

1.Conveyor feeding mode (For biomass particles)

2.Elevating automatic feeding (For coal)

3.Blast feeding (For size of less than 50mm of small sawdust, or

rice husk)

4.Screw feeder

Boiler application

Coal fired Hot water boiler is suitable for factories, schools,

office buildings, hotels, hospitals, etc. It can be used for

heating, bathing or providing sanitary hot water and water chiller

to form a complete set of cold and warm central air conditioning

system.