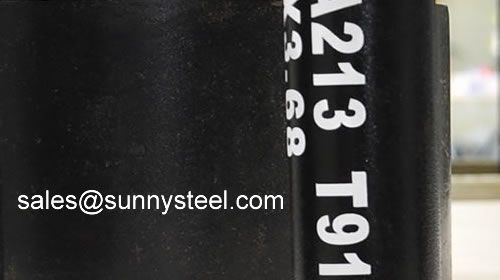

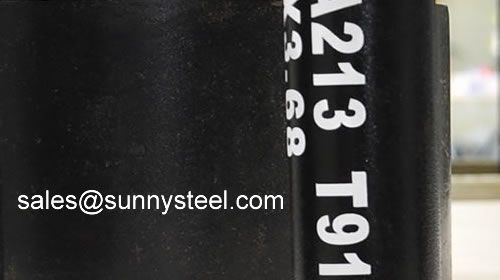

ASTM A**3 T*1 is the part of ASTM A**3 Standard

Specification for Seamless Ferritic and Austenitic

Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes.

ASTM A**3 T*1

ASTM A**3 T*1 Standard covers seamless ferritic and

austenitic steel boiler, superheater, and

heat-exchanger tubes.

Grades containing the letter H in their designation

have requirements different from those of similar

grades not containing the letter H.

These different requirements provide higher

creep-rupture strength than normally achievable in

similar grades without these different requirements.

ASTM A**3 T*1 tubes shall be made by the seamless

process and shall be either hot finished or cold

finished, as specified. Grade TP**7HFG shall be cold

finished. Heat treatment shall be done separately and

in addition to heating for hot forming. The ferritic

alloy and ferritic stainless steels shall be reheated.

On the other hand, austenitic stainless steel tubes

shall be furnished in the heat-treated condition.

Alternatively, immediately after hot forming, while the

temperature of the tubes is not less than the minimum

solution temperature, tubes may be individually

quenched in water or rapidly cooled by other means.

Tension test, hardness test, flattening test, and

flaring test shall be done to each tube. Also, each

tube shall be subjected to the nondestructive electric

test or hydrostatic test.

ASTM A**9 Through A**3

Other standard specifications include the categories of

A**9 seamless carbon-molybdenum alloy-steel boiler and

superheater tubes; A**0 seamless medium-carbon steel

boiler and superheater tubes and A**3 seamless ferritic

and austenitic steel boiler, superheater and

heat-exchanger tubes. Piping wall thicknesses range

from 1/2 inch to 5 inches. A**3 grades also have the

letter H or M assigned, which changes the composition

and specifications for that series.

This abstract is a brief summary of the referenced

standard. It is informational only and not an official

part of the standard; the full text of the standard

itself must be referred to for its use and application.

ASTM does not give any warranty express or implied or

make any representation that the contents of this

abstract are accurate, complete or up to date.