离岸价格

获取最新报价|

- Minimum Order

国家:

China

型号:

-

离岸价格:

位置:

-

最小订单价格:

-

最小订单:

-

包装细节:

-

交货时间:

-

供应能力:

-

付款方式:

-

联系人 Mr. Kai

No. 118, Gaoneng Street, High-Tech Zone, Dalian, Liaoning

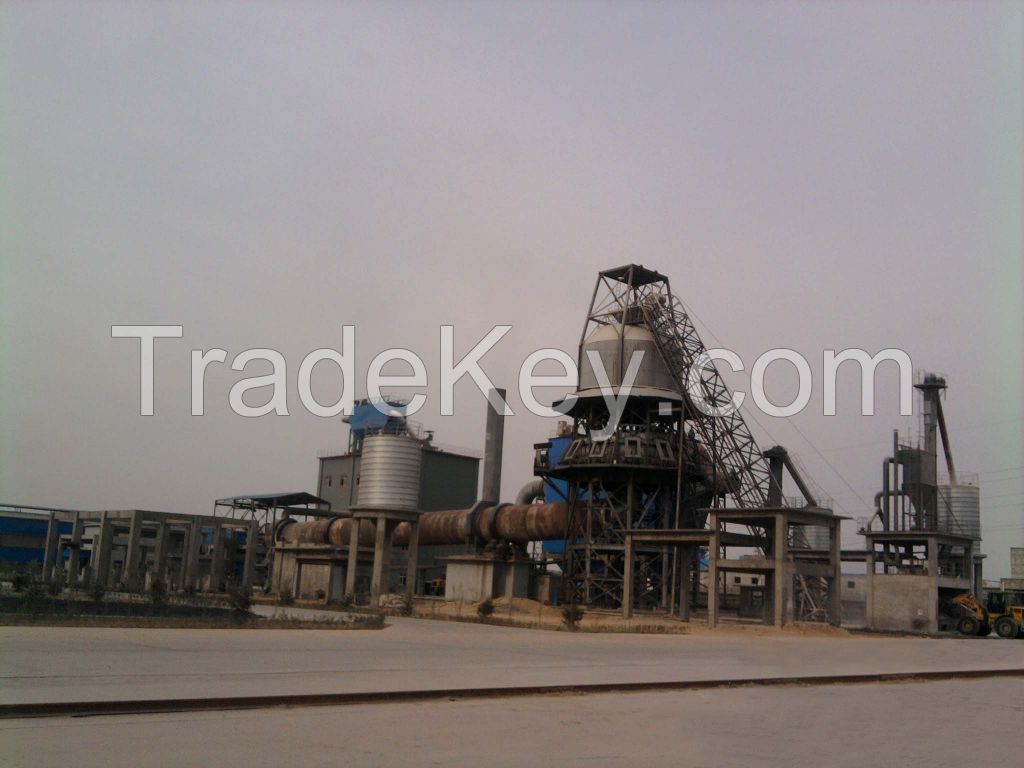

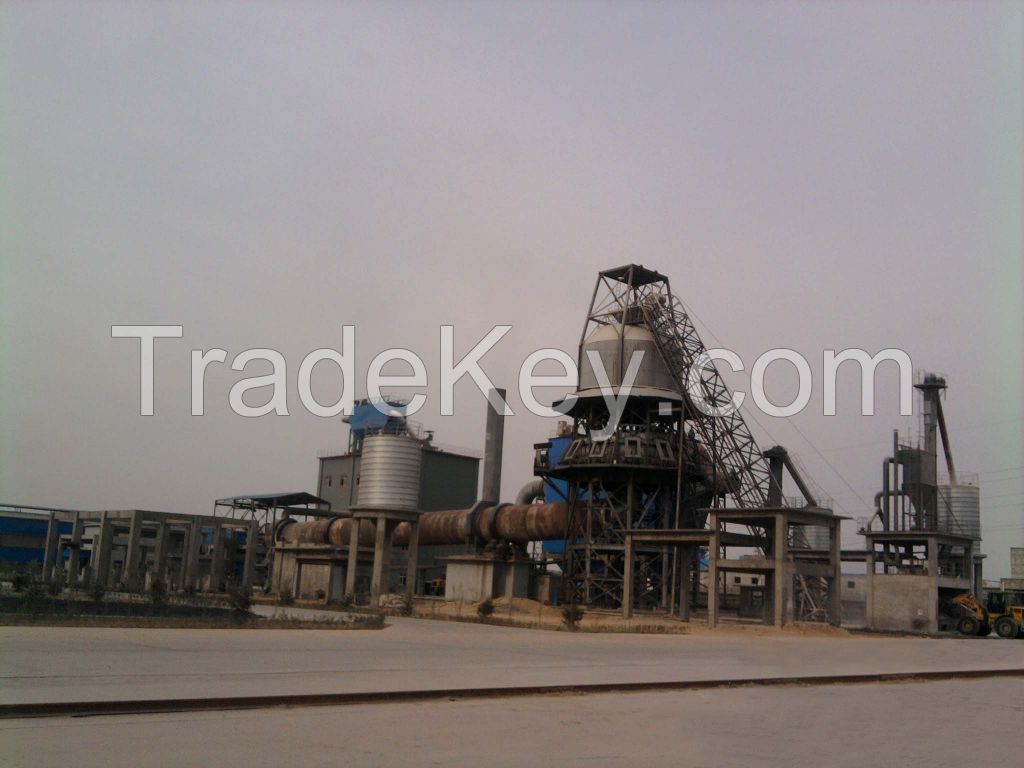

Complete Equipment for

Active Lime Production Line

1、Vertical Preheater

There is a bin on the top of

preheater and a level indicator that controls the height of

materials layer; materials slipping pipe, set between the bin and

preheater, can transfer limestone into preheater and meanwhile seal

the materials to prevent the entrance of cold air. Raw materials,

using waste gas of high temperature, moves in opposite direction of

materials feeding to achieve full heat exchange. The materials,

after being evenly preheated, are pushed into the kiln by hydraulic

push rod to reduce the time that materials are calcined in the

kiln. Flue gas is discharged into atmosphere after being treated by

dust collector.

| 国家: | China |

| 型号: | - |

| 离岸价格: | 获取最新报价 |

| 位置: | - |

| 最小订单价格: | - |

| 最小订单: | - |

| 包装细节: | - |

| 交货时间: | - |

| 供应能力: | - |

| 付款方式: | - |

| 產品組 : | Active Lime Production Line |