离岸价格

获取最新报价10 ~ 15 USD / Piece

|5 Piece Minimum Order

国家:

China

型号:

MS#MO002

离岸价格:

10 ~ 15 USD / Piece 获取最新报价

位置:

Henan

最小订单价格:

10 per Piece

最小订单:

5 Piece

包装细节:

Veneer cases or wooden cases or according to customers� requirement.

交货时间:

15-20 days

供应能力:

100000 Piece per Month

付款方式:

T/T, L/C, D/A, D/P, Western Union, Money Gram, PayPal

產品組 :

联系人 Tina

Xinxiang, Henan

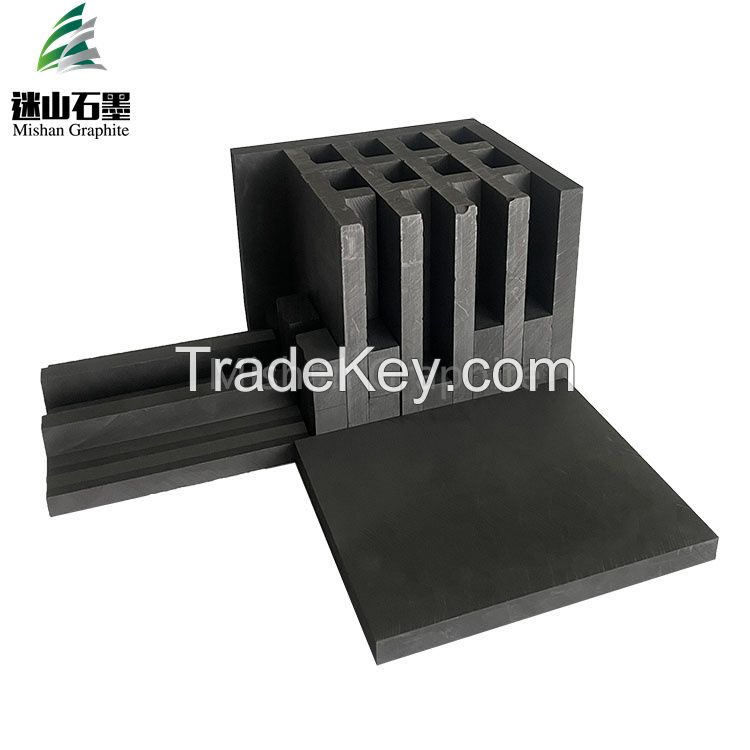

What is a diamond tool graphite mold?

Diamond tools are widely used in various industries to cut, grind,

drill and polish hard materials such as stone, concrete, ceramics,

glass and metal. These tools are made with high-quality diamond

abrasive grains and a bonding agent such as metal, resin, or

electroplated coatings.

One of the key components in making diamond tools is the graphite

mold, which shapes the metal bond around the diamond abrasive

grains. The mold is typically made from carbon graphite because of

its excellent thermal conductivity, high purity, chemical

inertness, and dimensional stability even at high temperatures.

However, not all graphite molds are created equal. The performance

and quality of diamond tools largely depend on the design and

accuracy of the mold. Improperly designed or constructed molds can

result in defects, variations in tool quality, poor productivity

and high costs.

Therefore, many diamond tool manufacturers choose to customize

carbon graphite molds to their specific needs and requirements.

These molds are designed and produced by graphite mold makers who

have the expertise to understand the complexities of diamond tool

production and the unique needs of each customer.

Custom carbon graphite molds for diamond tools offer many

advantages, such as:

• Improved tool quality and consistency: Well-designed graphite

molds produce high-quality tools with consistent geometry and

dimensions. This reduces scrap and rework and increases

productivity.

• Improve tool performance and durability: The accuracy of the mold

will affect the distribution of the metal matrix around the diamond

abrasive grains, thereby affecting the cutting performance, wear

resistance and service life of the tool.

• Reduced costs and lead times: Custom molds help reduce wastage of

material, time and energy. They also allow for faster prototyping

and scaling, resulting in shorter delivery times and increased

customer satisfaction.

• Flexibility and innovation: Custom tooling enables diamond tool

manufacturers to experiment with new tool designs, geometries and

materials. This can lead to innovative tools with unique properties

and applications.

In summary, custom carbon graphite molds are an important part of

producing high-quality diamond tools. They offer many advantages

over off-the-shelf molds, including improved tool quality and

consistency, improved tool performance and durability, reduced

costs and lead times, and flexibility and innovation. If you are a

diamond tool manufacturer looking to improve your production

process and tool quality, consider investing in custom graphite

molds from a reputable manufacturer.

| 国家: | China |

| 型号: | MS#MO002 |

| 离岸价格: | 10 ~ 15 / Piece 获取最新报价 |

| 位置: | Henan |

| 最小订单价格: | 10 per Piece |

| 最小订单: | 5 Piece |

| 包装细节: | Veneer cases or wooden cases or according to customersâ�� requirement. |

| 交货时间: | 15-20 days |

| 供应能力: | 100000 Piece per Month |

| 付款方式: | T/T, L/C, D/A, D/P, Western Union, Money Gram, PayPal |

| 產品組 : | Graphite Mold |