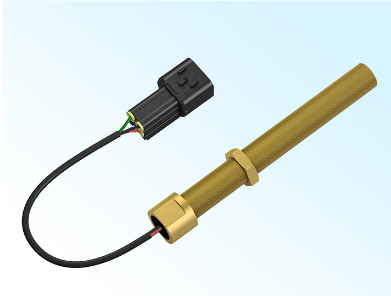

AH-Series Hall Gear Sensors

Product

Introduction

The Series AH Gear Sensor is a self-adjust gear speed sensor

that monitors the movement of titanium-like metals using a Hall

chip internally biased with a magnet and the output is in the

form of a digital sinking current output (open collector).

There is only a single Hall element in the sensor, so alignment

problems are out of concern. The Hall chip and its circuit are

sealed in a metal housing in the form of a probe, which can

effectively avoid electromagnetic interference and moisture. It

has a better SNR than electromagnetic induction sensors and

excellent low-speed performance to achieve "zero-speed"

detection. Currently, the sensors are widely used in the

following fields.

Application

○Camshaft and Crankshaft speed / position detection

○ Transfer speed detection

○ Speedometer

○ Anti-lock brake system (ABS system) Industry

○ Sprocket gear speed detection

○ Speed and distance detection

on chain conveyor belts

○ Stop motion detection

○ High-speed, low-cost proximity switches

Principle

The sensor is designed to sense changes in the magnetic field,

so the output state is changed when the magnetic flux density

reaches a certain value. In other words, the mounting position

of the sensor must be adjusted for different gears so that the

amount of change in magnetic field strength sensed by the Hall

chip in the product can be ensured to meet the operating

conditions. When the external gear rotates, the magnetic field

strength sensed by the Hall chip decreases from the maximum

value, and the sensor output state changes from low to high ,

and it changes into high level when the absolute value of

increment ΔB is greater than 100Gs; while the sensor output

state

changes from high to low when the magnetic field strength

increases from a very small value and it changes into low level

when the absolute value of increment ΔB is greater than

100Gs.