离岸价格

获取最新报价300000 / Set

|1 Set Minimum Order

国家:

China

型号:

FD

离岸价格:

300000 / Set 获取最新报价

位置:

China

最小订单价格:

300000 per Set

最小订单:

1 Set

包装细节:

standard container

交货时间:

20 working days

供应能力:

60 Set per Month

付款方式:

D/P, D/A, T/T

產品組 :

-

联系人 Ms. Sarah

No.1,Dahe West Road,Huiji District, Zhengzhou, Henan

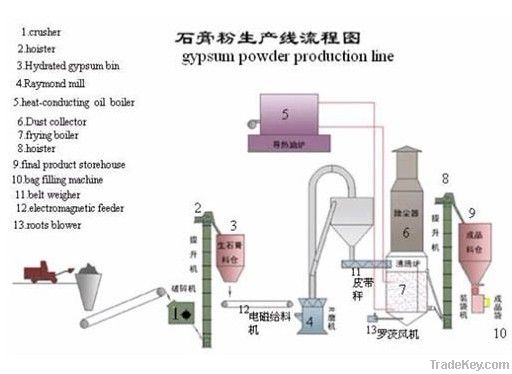

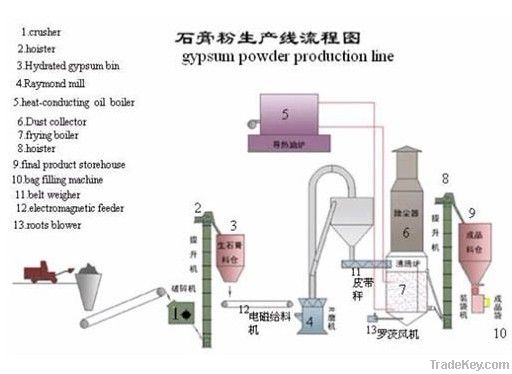

Gypsum powder production line has the advantages of First grind and

second bake.

Large plaster stone shall be ground into powders with diameter less

than 0.2mm, which increases the specific surface when calcining,

enlarges the contact area with heat medium, improves calcination

heat exchange efficiency and lowers energy consumption greatly.

This equipment has small bulk, large production capacity, and

simple structure and is hard to destroy.

Analysis on technique

features:

I. Concept of technique

Crusher grinds large gypsum into small granules less than *5mm.

After storage and measurement with weigh belt, transfer them into

Raymond mill for milling. Transfer qualified calcined gypsum powder

to clinker bin for storage or to board-manufacturing workshop for

usage.

II. Technique's advantages:

1.Features of first grind and second bake:

Compared

with that of first grind and second bake, the largest advantage of

this technique is great energy consumption reduction. The reason

lies in: great plaster stones are ground into powders with diameter

less than 0.2mm, which increases the specific surface when

calcining, enlarges contact area with heat medium, improves

calcining heat exchange efficiency and lowers energy consumption

greatly; the disadvantages are three powder pollution positions in

technical process, which shall be solved with dust-removing

equipment.

2. Features of two other techniques:

First bake and second grind: due to high energy consumption and

low production capability of this technique and that the quality of

the products is hard to control and is unstable, at present, it is

a kind of backward technique and is seldom adopted. Only a few

small factories are still applying it.

Integration of grind and bake: this technique has good features:

low energy consumption, small investment, high efficiency, stable

quality of the products and small area coverage. Besides, the dust

volume is concentrated and is easy for protecting environment.

However, it is not mature at home and only BNBM imported from

German one set of Peters-mill, which runs to manufacture thistle

board.

| 国家: | China |

| 型号: | FD |

| 离岸价格: | 300000 / Set 获取最新报价 |

| 位置: | China |

| 最小订单价格: | 300000 per Set |

| 最小订单: | 1 Set |

| 包装细节: | standard container |

| 交货时间: | 20 working days |

| 供应能力: | 60 Set per Month |

| 付款方式: | D/P, D/A, T/T |

| 產品組 : | - |