离岸价格

获取最新报价0.7 ~ 1.5 USD / Piece

|1000 Piece Minimum Order

国家:

China

型号:

-

离岸价格:

0.7 ~ 1.5 USD / Piece 获取最新报价

位置:

-

最小订单价格:

0.7 per Piece

最小订单:

1000 Piece

包装细节:

PE belt and wooden pallet

交货时间:

15days

供应能力:

50000 Piece per Week

付款方式:

-

產品組 :

联系人 Neva

Shijiazhuang, Hebei

**-We can promise you a short lead time ( ****5

days )

**-We have factory and can offer you direct price

**-We have good after-sale service offered, please get back if

you got question.

**-We have well trained & experienced staff to answer all

your enquiries in English of course.

**-Your business relationship with us will be confidential to

any third party.

**-Every year we export containers all over the world. With our

good quality products at competitive price and our

professional.

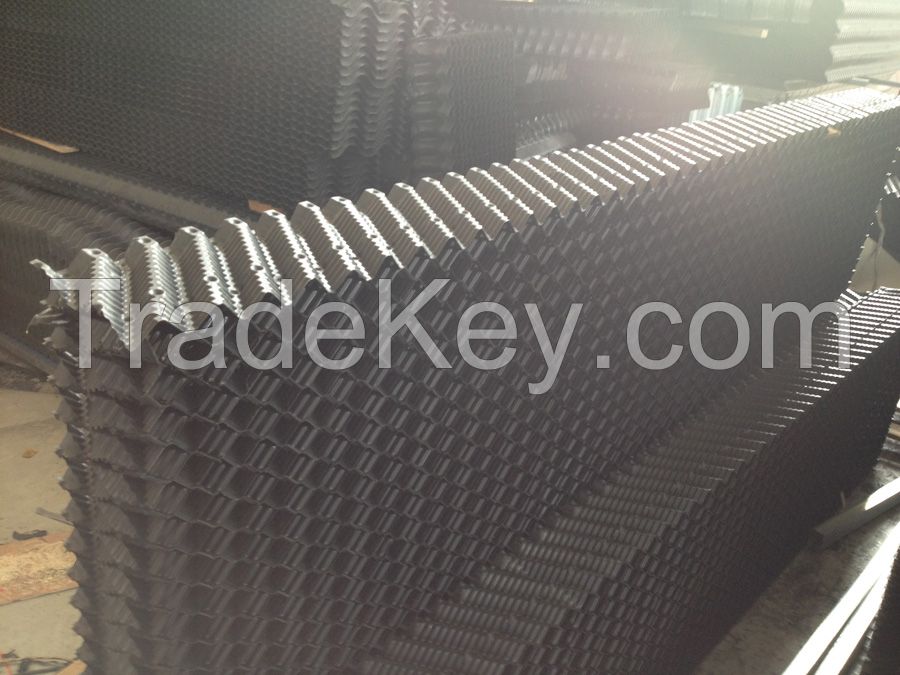

Cooling Tower Fill is one of the most important

components for exchange of gas and water in cooling tower. It

is the major parts to improve the efficiency of cooling tower

and make sure the economy and safe operation.With the

development of the plastic industry, counter-current tower

drench water plastic packing shape ladder wave, inclined

corrugated fills, which has the heat dissipation, durable, good

performance, ventilated small resistance, based on the easy and

other advantages. Counter-flow cooling tower fill with a *9mm

pitch. The larger sheet spacing is suitable for water quality

slightly less than ideal. RF***0 is used in counter-flow or

cross-flow cooling tower applications and is available in glued

blocks **5mm wide x **5mm high, and either ***0mm or ***0mm

long. RF***0 can also be cut to length to your specific

requirements, or supplied as loose sheets.

1.Original performance for lowest system

operating cost

2.Minimum downtime

3.Maximum service life

4.Operational safety

5.Easy maintenance

6.Easy cleaning

There are two main configurations of factory assembled cooling towers: cross flow and counter flow. In cross flow cooling towers, the water flows vertically down the fill as air flows horizontally across. In counter flow cooling towers, the water flows vertically down the fill as air flows vertically up.

| 国家: | China |

| 型号: | - |

| 离岸价格: | 0.7 ~ 1.5 / Piece 获取最新报价 |

| 位置: | - |

| 最小订单价格: | 0.7 per Piece |

| 最小订单: | 1000 Piece |

| 包装细节: | PE belt and wooden pallet |

| 交货时间: | 15days |

| 供应能力: | 50000 Piece per Week |

| 付款方式: | - |

| 產品組 : | cooling tower fill |