离岸价格

获取最新报价3.6 USD / Kilogram

|500 Kilogram Minimum Order

国家:

China

型号:

A05-01

离岸价格:

3.6 USD / Kilogram 获取最新报价

位置:

Ningbo, China

最小订单价格:

3.6 per Kilogram

最小订单:

500 Kilogram

包装细节:

pearl cotton each pcs and then carton

交货时间:

25 days

供应能力:

100 Ton per Month

付款方式:

T/T

產品組 :

China

联系人 Ms. yang

jiangbei district, Ningbo, Other

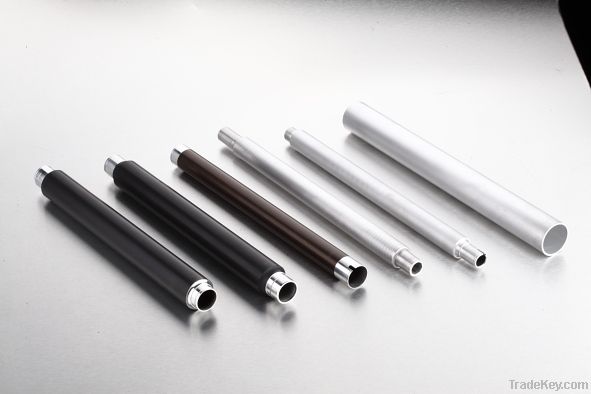

Magnetic roller is another main products filed of our company

together

with auto parts. In this OA series we have magnetic roller, heating

roller and OPC drum with customer of branded. This piece of magnetic

roller is made by AL***2 with the Temper of H*8. We have advanced

production machines such as extrusion machines, melting furnace, aging

furnaces, drawing machines and testing equipment including projector,

chemistry analyzer,Direct-reading spectrometer, balance, three harness

gauges and Romidot H**0 profile section inspection machine, etc. With

all of these equipment we can have a good control in processing and

inspection.

The processes of this products includes:extruding, air cooling,

straightening, cutting, heading, pumping, aligning, degreasing,

Stabilization treatment, inspection and then packaging and

transportation.During all these processes, we have five inspections

that are: incoming raw material inspection, aluminium billet

inspection, semi-finished profile inspection, finished products

inspection and then final inspection. Altogether five inspections

which ensure the quality and shape of our products.

We apply to JIS H***0 special level in flatness. Curvature and twist.

And tolerance according to GB/T********8 standards. And the whole

process passed the ISO***1:***8 quality management system.

As to surface treatments, we have anodizing with many different colors

and oxidation films; powercoating applied to VAL system and cast

blasting, etc.

Also we have a firm delivery time of *5 days.

Therefore we can sure that we can meet your requirement both in

quality and quantity with our good quality, competitive price, firm

delivery and good after-sale service.

| 国家: | China |

| 型号: | A05-01 |

| 离岸价格: | 3.6 / Kilogram 获取最新报价 |

| 位置: | Ningbo, China |

| 最小订单价格: | 3.6 per Kilogram |

| 最小订单: | 500 Kilogram |

| 包装细节: | pearl cotton each pcs and then carton |

| 交货时间: | 25 days |

| 供应能力: | 100 Ton per Month |

| 付款方式: | T/T |

| 產品組 : | Aluminium OA series |