离岸价格

获取最新报价6000 ~ 8000 USD / Set ( Negotiable )

|1 Set Minimum Order

国家:

China

型号:

SD -650

离岸价格:

6000 ~ 8000 USD / Set ( Negotiable ) 获取最新报价

位置:

�¦�±ï¿½�¨ï¿½ï¿½�§ï¿&Ac

最小订单价格:

6000 per Set

最小订单:

1 Set

包装细节:

All be packed in wooden crates ( Fumigation Free) or as customer's special request.

交货时间:

Within 7--15 days after receiving advanced payment

供应能力:

500 Set per Year

付款方式:

T/T, L/C

產品組 :

China

联系人 Wang

Wuxi, Jiangsu

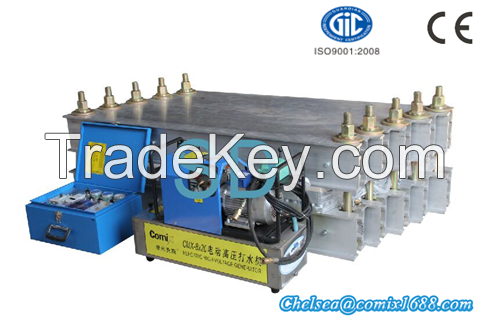

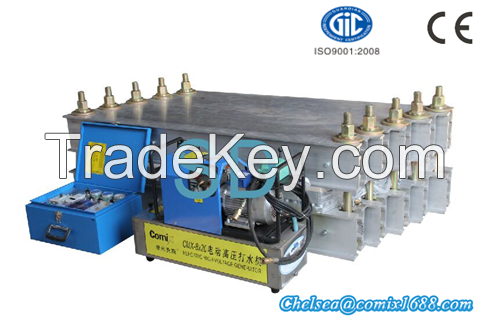

Our products are mainly applied to industries for splicing and repairing for conveyor belts such as metallurgy, mine, power plant, port, dock, construction material cement, chemical industry , tobacco ,and food automatic line field.

1.Machine Maximum

size: from **0MM****0MM;

2.Voltage: **0V

**0V **5V **0V *0HZ;

3.Fast

Cooling time: *5 minutes (from **5 degrees down to *0

degrees or less);

4.Time

for temperature raise (from normal temperature to

vulcanizing temperature) no morethan *5

minutes;

5.The

temperature difference of sulfide surface:

±2°c.6.Temperature

adjustment range: 0~**0°c.

7.Vulcanizing

pressure: 0~2.5 MPa (details refer to users

specifications and factory markings);

8.Time

of heat preservation for vulcanizing could be adjusted

according to thickness of the rubber belts;

9.

Splicing length of rubber conveyor belt for vulcanizing

jointing could be connected together by

single

or several pieces if necessary;

*0. rubber

conveyor belt as well as tension in kilogram required for

vulcanizing jointing when ordering

products.

*1.

Users could order spare electric pumps additionally

according to requirements.

1.Our

vulcanizing machines and repair machines adopt the unique

technology full-automatic and precision digital control

system. Vulcanizing temperature is uniform and accurate.

Vulcanization pressure is also uniform, It is easy to be

operated. The weight is lighter than the original one.

Quality is reliable and durable. Our level is much higher

than the counterparts both in China and abroad

.

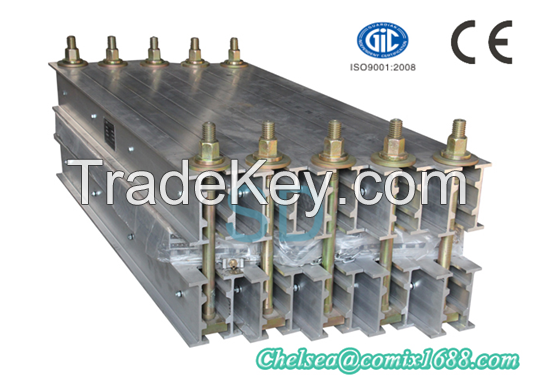

2. The

upper and below heating plate

We choose aluminum alloy material with high quality and

adopt high strength aluminum alloy to manufacture.

The process is special, its characteristics are as

follows:

(1)It has small volume and light weight(as half as

before),the consumption is low and heating is very fast.

After heating, the whole piece of board face is very

flexible , more close to the tape than the conventional

machine .Under the pressure of 1.5 mpa, the parallel

close is not more than 0.*3 mm, but the conventional

machine does not have the performance.

(2)Various points of upper and below heating plate can be heated uniform .After heating for*0 min, the temperature difference of the each point in the face is only + / - 3 ℃ ~ 4 ℃, which surpasses the international standard.

(3)The temperature can rise from the normal temperature to the curing temperature (**5 ℃) in less than *5 min. The power is half lower than the same factories in China or at abroad .The energy saving effect is good.

(4)Vulcanization or repairing can be finished in one time, the splicing parts are smooth, bright and clean, the fastness is no difference from the original belts.

(5)Heating layer, clip heat layer are the trinity, the structure is simple ,and it is easy to install.

3.Water cooling ( it can be made according to customer requirements!)

The heating layer is equipped with the international advanced once-through water cooling loop device, it takes only about *5 minutes to cool rapidly from **5 ℃ high temperature to *0 ℃, which speed up the progress of cementing and increase strength of the belt joints, and also maintain of belt joints.

4. Hand shank

The handle has SD soft connection characteristics. It is not hot under the high temperature operation. The appearance is plating chromium and bright beautiful. And it seems small and exquisite.

5.Water pressure plate

(1) The water pressure plate adopts international advanced technology , because of its special structure, the overall can be pressed uniform, The plate experiences numerous high pressure tests. No leakage phenomenon appears under 1.**5 mpa, *0 min high pressure test, which is higher than the international standard.

(2) The water pressure plate can be hydraulic and pneumatic

6. The Plug of the Power Input Wire cord

Power Input Wire adopts special five core with one flat plug, which changes the disadvantages of conventional multiple line plug and indeed simplify the line.

7.Automatic electrical control box

(1)Automatic electric cabinet and electrical components select intuitive LCD digital display instrument, which are with good quality and durability. Numbers and lights show, preinstall curing time and temperature. The vulcanization process is fully automatic operated. The alarm lights light ,the work will be finished automatically.

(2) Automatic LCD digital display temperature control box looks elegant, small and exquisite, and adopt advanced vertical double waterproof technology. The outer garment is dustproof and waterproof, which can be operated in the dust, heavy rain and other bad weathers.

(3)Equipped with the leakage automatic switch ,which has the overload, short circuit, leakage protection performance to ensure personal safety.

(4) Because of circuit integration, automatic operating procedure and unified plug , the electric cabinet can be connected with all vulcanizing machines and repair machines in our factory. The conventional machine cant have this performance.

8. Rod, nut

Only

starting point for cooperation, the service does not

end.

Your enquiries, we will give feed back at the first

time.

Your

requests, we will meet at the first

time.

Your goods,

we will arrange at the first time.

Your questions, we

will solve at the first time.

| 国家: | China |

| 型号: | SD -650 |

| 离岸价格: | 6000 ~ 8000 / Set ( Negotiable ) 获取最新报价 |

| 位置: | Ã�¦Ã�񋨫Ã�¨ï¿½ï¿½Ã�§ï¿&Ac |

| 最小订单价格: | 6000 per Set |

| 最小订单: | 1 Set |

| 包装细节: | All be packed in wooden crates ( Fumigation Free) or as customer's special request. |

| 交货时间: | Within 7--15 days after receiving advanced payment |

| 供应能力: | 500 Set per Year |

| 付款方式: | T/T, L/C |

| 產品組 : | SD Vulcanizing Machine |