离岸价格

获取最新报价( Negotiable )

|- Minimum Order

国家:

China

型号:

WW1530L

离岸价格:

( Negotiable ) 获取最新报价

位置:

CHINA

最小订单价格:

-

最小订单:

-

包装细节:

Bubble wrap inner packaging & cartons for outer packing

交货时间:

Within 15 days or according to customer requiremen

供应能力:

100 Set per Week

付款方式:

T/T

联系人 Emma

Hangzhou, Zhejiang

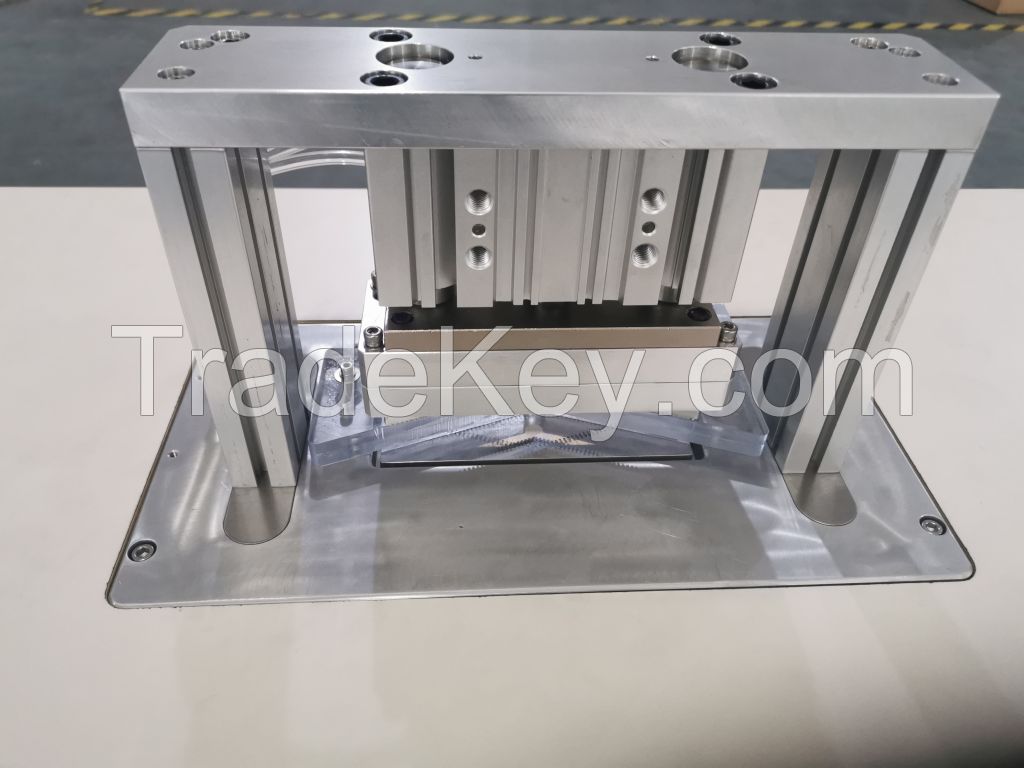

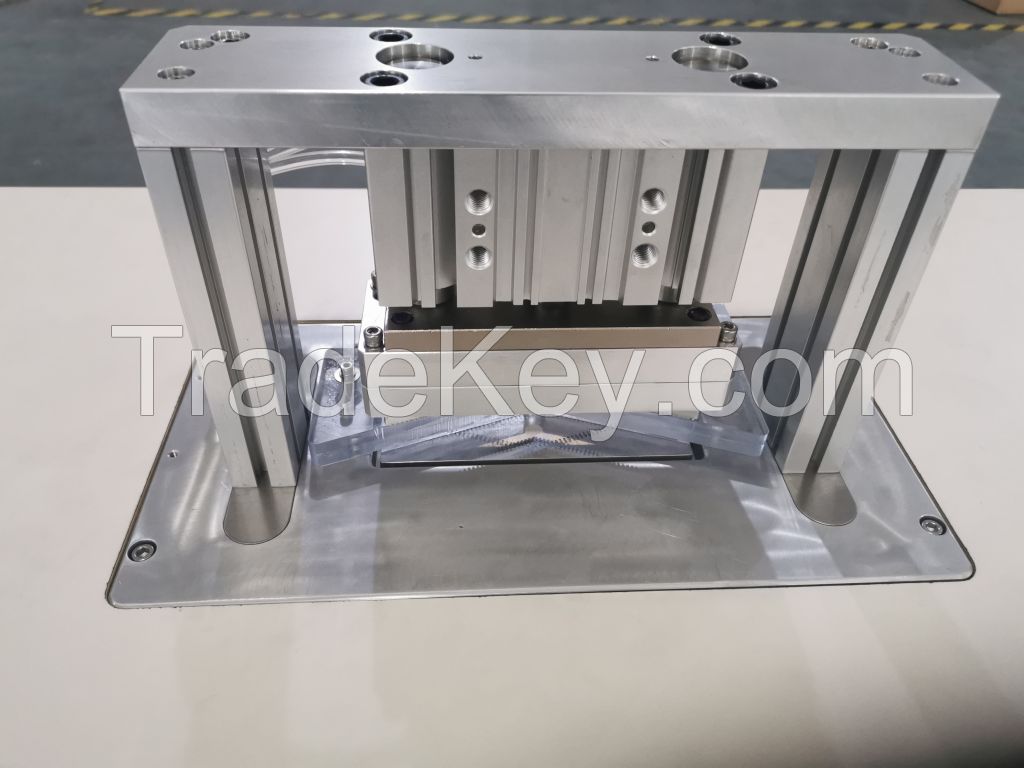

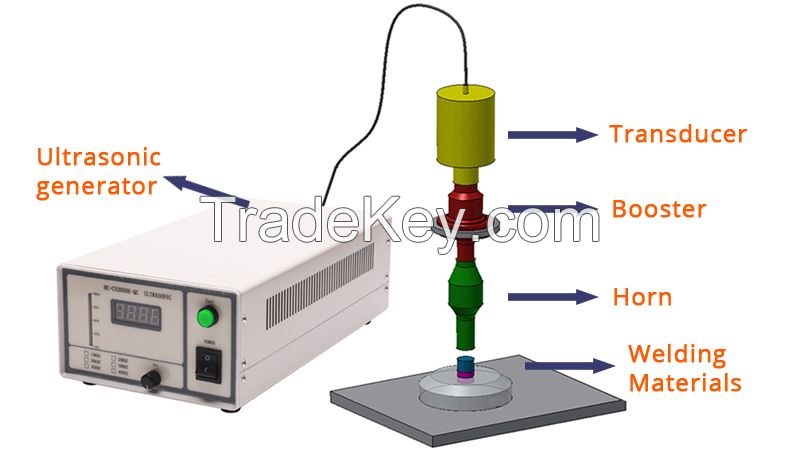

Ultrasonic welding is a process used to join two

plastic parts together to form a strong, finished assembly. The

process relies on high-frequency (ultrasonic) vibrations being

generated and applied to the parts via a horn. Welding occurs as

the vibrations are absorbed in the interface between the two parts,

generating friction and causing the plastic to melt. The ultrasonic

vibrations are generated by a series of components, including the

power supply, converter, booster and horn, which ultimately

delivers the mechanical vibration to

the parts.

The role of the power supply is to

convert the incoming line voltage (at *0 or *0Hz) into a new

frequency. This electrical energy then is sent to the converter,

which as the name implies, converts the electrical energy into

mechanical vibrations. The converter consists of piezoelectric

ceramic discs, which expand and contract at the rate of the

supplied electrical energy. The magnitude of the vibrations is

referred to as amplitude, a term that becomes very important when

specifying an ultrasonic system for a given application. The

vibrations then are transmitted through the booster, which

typically increases the amplitude by a predetermined multiple, also

known as gain. Finally, the boosters output amplitude is

transmitted through the horn, where it then can be delivered to the

plastic parts.

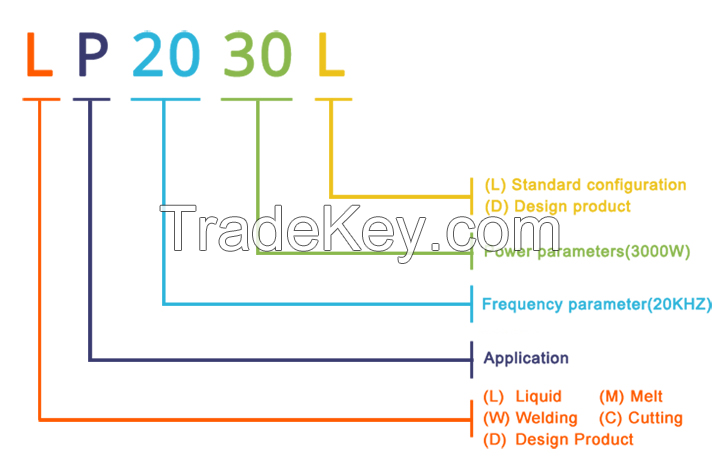

| Attributes | Parameter | Attributes | Parameter |

| Brand | HCSONIC | Item Model | WW***2L |

| Maximum Power output | ***0W | Frequency | *5KHZ |

| Maximum Amplitude | *0µm | Working model | Continuous, intermittent |

| Weldable materials | Thermoplastic materials | Welding Head Material | Steel |

| Welding Head Size | **0**5mm | Driven Type | Electric |

| Technical Support | Video, mail, phone | Warranty | One year, except horn |

| Full Set Weight | *1KG | Place of Origin | China |

| 国家: | China |

| 型号: | WW1530L |

| 离岸价格: | ( Negotiable ) 获取最新报价 |

| 位置: | CHINA |

| 最小订单价格: | - |

| 最小订单: | - |

| 包装细节: | Bubble wrap inner packaging & cartons for outer packing |

| 交货时间: | Within 15 days or according to customer requiremen |

| 供应能力: | 100 Set per Week |

| 付款方式: | T/T |

| 產品組 : | ultrasonic welding machine |