离岸价格

获取最新报价200 ~ 800 USD / Square Meter

|1 Piece Minimum Order

国家:

China

型号:

WD-thickness

离岸价格:

200 ~ 800 USD / Square Meter 获取最新报价

位置:

Tianjin, China

最小订单价格:

200 per Square Meter

最小订单:

1 Piece

包装细节:

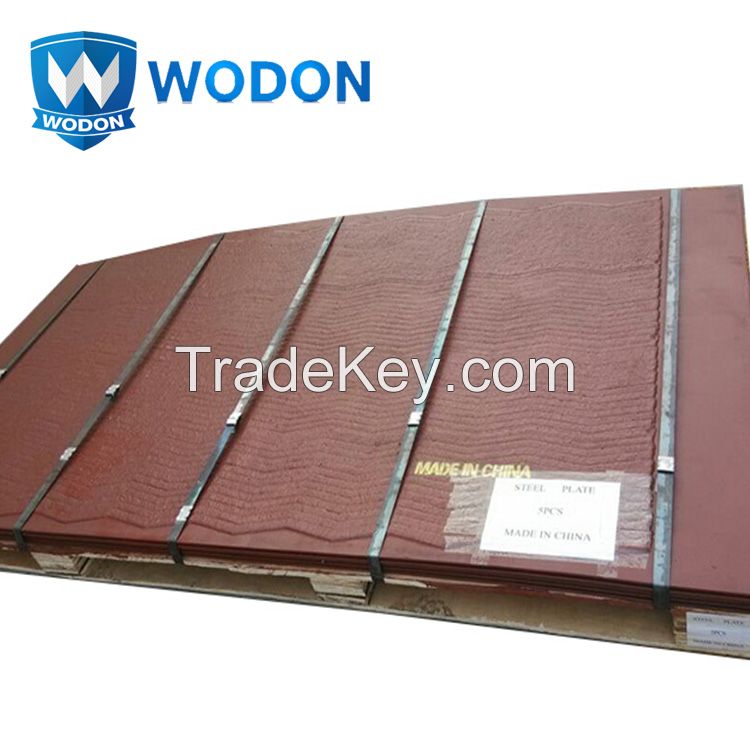

Packing on the steel pallet with plastic film

交货时间:

7~10 Days

供应能力:

90000 Square Meter per Year

付款方式:

T/T

產品組 :

联系人 Mr. Alexander

Room 1901, Building 5, Beichen Block, Beichen District, Tianjin City, China, Tianjin, Tianjin

What is Wodon wear plate?

Wodon wear resistant steel plates are manufactured by welding one or multiple abrasion resistant layers on a medium or low carbon steel base plate. The overlay alloy has a high amount of chromium carbide hard particles. These particles are distributed evenly throughout the layer, creating a strong microstructure. The hardness is HRC *8~*5 and depends on the overlay's thickness.

The main ingredients of Wodon plate are C (%): 3.0~5.0 and Cr (%): *5~*0. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV***0) of these particles thoughout the layer will guarantee a super wear resistant surface.

The overlay and base plate are metallurgical bonding. The overlay will penetrate into base plate about 0.8~1.8 mm, reaching up to **0 Mpa in our tests.

| Product name | WODON manufactured wear plate with wear resistant welding layer |

| Material | Q**5/Q**5+Chromium carbide overlay alloy |

| Certificate | ISO***1:***8 |

| Chemical composition | C: 3.0~5.0 % Cr: *5~*0 % |

| Microstructure |

Chromium carbide hard particles volume fraction above *0 % The maximum hardness of chromium carbide is HV ***0 |

| Wear Resistance | Our test shows that the wear resistance of Wodon plate is *0 times higher than low carbon stell and *2 times than heat treated steel |

| Impact resistance | Wodon wear plates can withstand medium impact |

| Temperature resistance | Wodon wear plates can withstand temperatures up to **0 ℃. We can customize high temperature resistance wear plates according to customer's requirements which can withstand maximum terperatures up to **0 ℃ |

| Flatness tolerance | ± 3 mm/m |

| Thickness tolerance | Uniform overlay thickness, with tolerance within 0~0.5 mm |

| Surface treatment | hardfacing, cladding, open arc or submerged arc welding |

| Standard sizes |

Open arc welding: ***0****0 mm, customized Submerged arc welding: ***0****0 mm, ***0****0 mm, ***0****0 mm, customized |

|

The main thicknesses (mm) |

3 on 3, 4 on 4, 5 on 5 4 on 6, 5 on 6, 6 on 6, 8 on 6 4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8 4 on *0, 5 on *0, 6 on *0, 7 on *0, 8 on *0, 9 on *0, *0 on *0, *0 on *0 4 on *2, 5 on *2, 6 on *2, 7 on *2, 8 on *2, *0 on *2, *1 on *2, *2 on *2 6 on *4, 8 on *4, *0 on *4 6 on *6, 8 on *6, *0 on *6 6 on *8, 8 on *8, *0 on *8 5 on *0, 6 on *0, 8 on *0, *0 on *0, *0 on *0, *0 on *0, *0 on *0 Customized

|

Wodon wear plates are used to make many complex wear parts to be positioned in high wear places. We have several equipment to transform our plates: six of CNC automatic plasma cutting machine, 4 multi functional bending machines and pressing machines, with high processing capacity operated by engineers and technical experts. We can provide wear plate cutting, bending, punching and welding according to customer's drawings.

1. Chemical Composition: High carbon high chromium

2. Hardness: HRC****5

3. Good Performance: good mechanical processing propertie to be cut, bended, punched, bolted and welded, smooth surface with uniform overlay, super wear resistance, medium impact resistance, good heat resistance.

5. Production Capacity: *0,**0 square meters per year

6. Short Delivery Time: Generally 7 days according the quantity

7. We have many experienced professionals to research and develop wear plates according to customers' specified chemical compositions.

8. We can recommend proper wear plates and provide technical solutions based on working conditions.

9. on site inspection and third party inspection are available.

*0. As an ISO***1:***8 approved manufacture, our mission is to improve our management system and provide high quality products continuously.

We have our own Quality Inspection Technology Department and the team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In the pictures you can also see our equipment in our laboratory. Our inspection team make regular testing on raw material, production process and our products according our company's strict policy.

In our

Laboratory there are the Rockwell Hardness tester to test the

Hardness of the small welding samples, the portable Spectrum to

test the chemical compostion easily at the work pieces on the

scene, the portable Hardness tester to test the Hardness easily at

the work pieces on the scene and the portable ultrasonic thickness

measurement instrument to test the thickness easily and

accurate.

There are also abrasion resistance testing machine and a series

of metallograhy experiment instruments, so the metallurgical

microstructure and wear resistance can be tested.

The

below picture shows our laboratory. There are many equipments

to suppert our Quality Inspection Technology Department, for

sample: a series of metallographic

analysis equipments, protable spectrum, protable

ultrasonic thickness

tester, protable ultrasonic hardness tester, destop Rockwell

hardness tester, Infrared carbon sulfur analyzer, Quartz sand

rubber wheel abrasion test machine and Reciprocating abrasion

tester.

We are certified with the ISO***1:***8 and keep continuously improving our quality management system. We have strict procedures for raw materials, products inspection, production process, storage management and after sales service.

We are certified with the ISO***0:***4 and keep continuously improving our environmental management system. We use the electric boiler not the coal fired boiler to protect the environmental. We use the advanced dust removal and ventilation equipment to keep the air clean.

We are certified with the OHSAS*********7 and keep continuously improving our occupational health and safety management system. Our every technical staff wears filter mask, protective clothing and gloves and welding goggles.

Q: Are you trading company or manufacturer ?

A: We are manufacturer with more than 3 factorys, our own sales department and our own inspection technology department.

Q: How long is your delivery time?

A: Generally it is ***0 days if the goods are in stock. or it is ****0 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:*0% T/T in advance ,balance against copy of BL.

also, FOB, CIF, CFR all are available for your product.

If you have another question, pls feel free to contact us as below:

| 国家: | China |

| 型号: | WD-thickness |

| 离岸价格: | 200 ~ 800 / Square Meter 获取最新报价 |

| 位置: | Tianjin, China |

| 最小订单价格: | 200 per Square Meter |

| 最小订单: | 1 Piece |

| 包装细节: | Packing on the steel pallet with plastic film |

| 交货时间: | 7~10 Days |

| 供应能力: | 90000 Square Meter per Year |

| 付款方式: | T/T |

| 產品組 : | wear plate |