详情

1900C U shape Molybdenum Disilicide MoSi2 Heater for Industrial and

Laboratory Furnace

VINER Industrial U

shape Molybdenum Disilicide MoSi2 Heater is esistance generate-heating component made

from MoSi2 or the basic material. It is used in high temperature

under the oxidizing atmosphere, it looks like glass in its surface

and form a light SiO2 glass film which can protect the element not

to be oxidized. So this kind of element has unique effect for

resisting oxidization in the high temperature. It is used to the

highest temperature up to 1800C during oxidizing atmosphere.

According to your request, our company can produce the products of

Pole, "U", "W" and "U"-right angle shapes,

etc.

VINER Industrial U

shape Molybdenum Disilicide MoSi2 Heater can

usually make use of furnace temperature from 1300C to 1900C. It is

extensively used in the industries of metallurgy, glass, ceramic

refractory, crystal electronic device, industrial furnace

manufacture, etc. It is an essential ideal element when the

products are sintering in the high

temperature.

U shape Molybdenum Disilicide MoSi2 Heater Physics and Chemistry

Characters:

1.

Physics Characters

|

Volume

Density

|

Bending

Strength

|

Vickers

Hardness

|

Porosity

|

Water

absorption

|

Heating Elongation

Rate

|

|

5.5 g/cm3

|

15-25 kg/cm3

|

(HV)570kg/mm2

|

7.4%

|

1.2%

|

4%

|

2. Chemistry

Character

VINER Industrial U

shape Molybdenum Disilicide MoSi2 Heater

is

used in the high temperature under oxidizing atmosphere. It will

form the SiO2 film which can keep the element from being melted.

During the oxidizing process, the SiO2 protecting film is formed

again when the element continues to be used. The MoSi2 heating

element must not be used in the temperature between 400C and 700C

for a long time, otherwise the element will be cremated under the

strong oxidizing function in the low

temperature.

Now, VINER Industrial supply 3

types U shape Molybdenum

Disilicide MoSi2 Heater

,

one is 1700 type, which ensure max. furnace temperature 1650C; one

is 1800 type, which ensure max. furnace temperature 1700C; another

one is 1900 type, which ensure max. furnace temperature 1800C. When

you place order, please choose suitable type according to your

furnace working temperature.

1700 (heat furnace temperature

1650C)

1800 (heat furnace temperature

1700C)

1900 (heat furnace temperature

1800C)

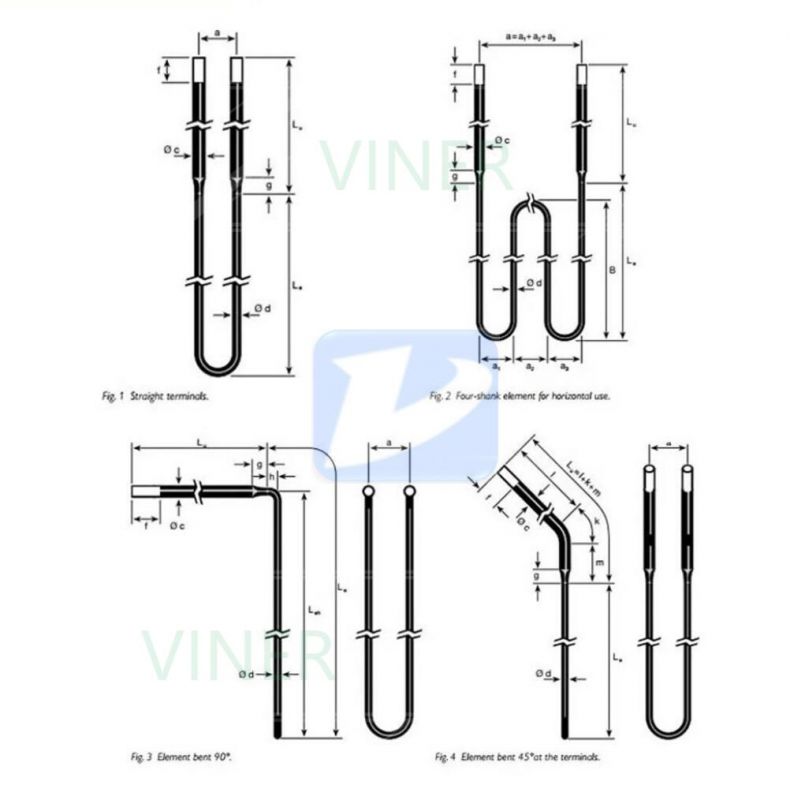

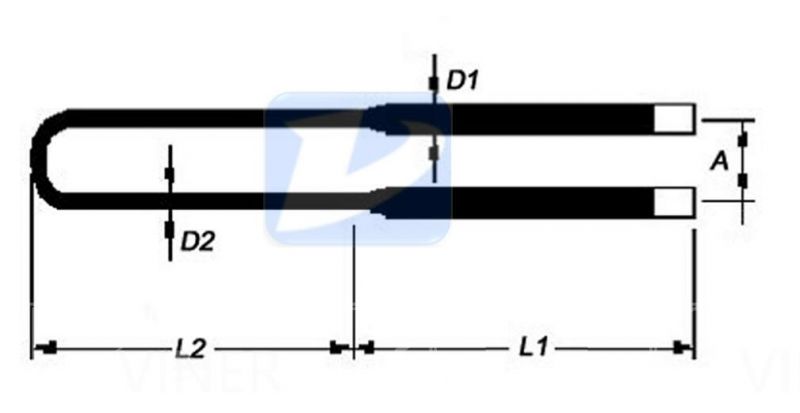

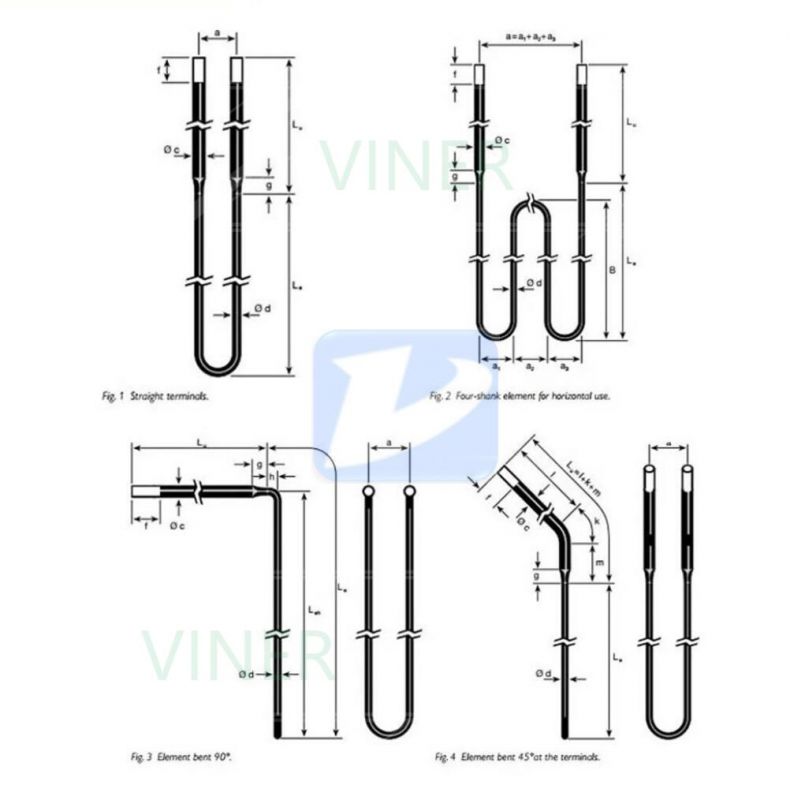

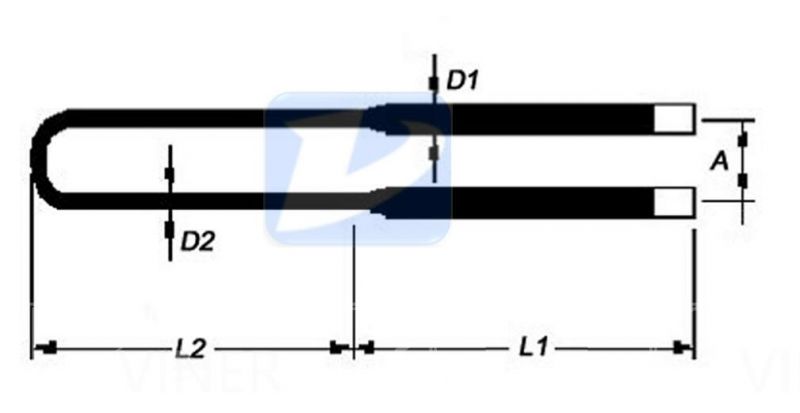

When you place an order of the VINER

Insutrial U shape Molybdenum

Disilicide MoSi2 Heater

,

please give following information:

Material Grade:

1700/1800/1900

C:

Hot Zone Diameter

D:

Cold Zone Diameter

Lu:

Cold Zone Length

Le:

Hot Zone Length

A:

Shank Spacing

Order Sample of the VINER

Industrial U shape Molybdenum

Disilicide MoSi2 Heater

:

Material Grade: 1800, c=3mm, d=6mm, Le=140mm, LU=125mm,

A=25mm

Specify

As:3/6×140×125×25

U shape Molybdenum Disilicide MoSi2 Heater

Installation:

The

brittleness of MoSi2 heating element is relative more under the

usual temperature, it also has plasticity under the high

temperature. So you had better hang and erect vertically the

"U"-shape element. If you need to erect it horizontally, please

choose a support of high-temperature insulating materials. The

cone-part of the element must extend inside the furnace. At first

the fixture of MoSi2 power connector cant be screwed too

tightly. When temperature of the element is going up, please

twist it tightly again, so the element is not easily broken.(our

suggestion: please choose the specialize power connector provided

by our company)

The

furnace top must be a good function of heat-preservation. In

general, the temperature of furnace top cant be over 300C. The

voltage should be low 0.1 between the power connector and the

element. In order to avoid radiating heat to pass the connector,

the distance is not less than 50mm between the low end of connector

and the upside of the ceramic brick. The Dia.6 element cant be used

of 170A for a long time. The Dia.9 element cant be used of 300A for

a long time.

Notice to Furnace

Operation:

To

avoid high current surges which may cause damage to MoSi2 heating

elements, the recommend starting procedure as

following:

|

Small Furnace (Power

100kw)

|

Big Furnace (Power

100kw-500kw)

|

|

Furnace Temperature

.C

|

Voltage

|

Furnace Temperature

.C

|

Voltage

|

|

20-150

|

1/3

|

20-300

|

1/3

|

|

150-500

|

2/3

|

300-700

|

2/3

|

|

500-Working

Temperature

|

Full

|

700-working

Temperature

|

Full

|

|

Note:Shifting

gear must be done quickly, otherwise high current surges

may cause damage.

|

U shape Molybdenum Disilicide MoSi2 Heater

Packaging:

In

Standard Wooden Case, VINER Industrial could be lifting

packing.

U shape Molybdenum Disilicide MoSi2 Heater

Shipment:

VINER Industrial could supply you the follow

shipping way for your choice:

--By DHL/Fedex (Door to door, Home delivery

service)

--By Air to your nearest

Airport

--By Sea to your nearest

Seaport

--By the sellers shipping

agent

According to your request, our company can

produce the products of MoSi2 heating elements, "U", "W" and

"U"-right angle shapes, etc.

Welcome to visit manufacture line!! Wait for

your testing our high temperature MoSi2 heating

elements!!

Company

Information

VINER Industrial specializes

in U type MoSi2 heating

Rod

1700, 1800, 1900, have U, W, L and Special

shape several types with diameter 3/6, 4/9, 6/12/, 9/18, 12/24mm.

SiC heating elements with ED (Rod, Straight) type, U type, W type,

L type, Slot type, Single Spiral, Double Spiral, UX type and

diameter 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm,

31.7mm (1.25inch), 35mm, 38.1mm (1.5 inch), 40mm, 44.4mm (1.75

inch) to 54mm (2.125 inch), 75mm (2.95

inch).

Also different sizes and kinds of high

temperature furnaces including Muffle Furnace, Vacuum Tube furnace,

Vertical Tube Furnace, Rotary Tube furnace, Vacuum Crucible

furnace, Vacuum Box furnace, Atmosphere Furnace, Bottom Loading

furnace, and Vacuum Drying Oven, the chamber sizes could be

according to customers' design. What is

more,VINER

Industrialproduces and supplies high temperature Kiln

Furnace Spare Parts including MoSi2/SiC/Resistance Wire heating

elements, Ceramic Fiber Insulation, Alumina/Zirconia Ceramics,

Silicon Carbide Ceramics, Boron Nitride (BN) Ceramics, Vacuum

Flanges, Thermocouple, PID Temperature Controller, and Quartz

Furnace Tube. Ps kindly inquiry us, we will try our best to serve

you.

Welcome to visit manufacture

line!!

Guaranteed

Quality: Our

MoSi2/SiC heating elements are warranted to be free from defects in

materials or workmanship for 1 years from the date of purchase.

Within this period, Across International will, at its sole options,

replace any components that fail in normal use. Such replacement

will be made at no charge to the customer for parts, provided that

the customer shall be responsible for any transportation cost. This

warranty does not cover consumables and failures due to abuse,

misuse, accident or unauthorized alteration or

repairs.

Sound after Sales

Service: We

provide sound after sales service. We provide 24 hours consultation

service. We are ready to answer your consultations at any

time.

Our

Services

1.

Your inquiry related to our products or prices will be replied within 24hours

2. Guarantee samples quality same as mass

production quality

3. All our products have 2-years warranties.

4. Offering the support to solve the problem in the application or selling period.

5.

Competitive prices based on same

quality

FAQ

1.

Can you accept OEM?

Yes! We can manufacture as per your

request size.

2.

Can you deliver the goods via our shipping

agent?

Yes, we could help you make the delivery

using your shipping agent

3.

Can you supply sample:

We could like to give you suitable suggestion about the

SiC heating elements

according to your detail application.

4. What about your

After-sales service:

We promise that we can change or refund products if there are any quality problem.

Also different sizes and kinds of high

temperature furnaces including Muffle Furnace, Vacuum Tube furnace,

Vertical Tube Furnace, Rotary Tube furnace, Vacuum Crucible

furnace, Vacuum Box furnace, Atmosphere Furnace, Bottom Loading

furnace, and Vacuum Drying Oven, the chamber sizes could be

according to customers' design. What is

more,VINER

Industrialproduces and supplies high temperature Kiln

Furnace Spare Parts including MoSi2/SiC/Resistance Wire heating

elements, Ceramic Fiber Insulation, Alumina/Zirconia Ceramics,

Silicon Carbide Ceramics, Boron Nitride (BN) Ceramics, Vacuum

Flanges, Thermocouple, PID Temperature Controller, and Quartz

Furnace Tube. Ps kindly inquiry us, we will try our best to serve

you.

Welcome to visit manufacture

line!!

Guaranteed

Quality: Our

MoSi2/SiC heating elements are warranted to be free from defects in

materials or workmanship for 1 years from the date of purchase.

Within this period, Across International will, at its sole options,

replace any components that fail in normal use. Such replacement

will be made at no charge to the customer for parts, provided that

the customer shall be responsible for any transportation cost. This

warranty does not cover consumables and failures due to abuse,

misuse, accident or unauthorized alteration or

repairs.

Sound after Sales

Service: We

provide sound after sales service. We provide 24 hours consultation

service. We are ready to answer your consultations at any

time.

Our

Services

1.

Your inquiry related to our products or prices will be replied within 24hours

2. Guarantee samples quality same as mass

production quality

3. All our products have 2-years warranties.

4. Offering the support to solve the problem in the application or selling period.

5.

Competitive prices based on same

quality

FAQ

1.

Can you accept OEM?

Yes! We can manufacture as per your

request size.

2.

Can you deliver the goods via our shipping

agent?

Yes, we could help you make the delivery

using your shipping agent

3.

Can you supply sample:

We could like to give you suitable suggestion about the

SiC heating elements

according to your detail application.

4. What about your

After-sales service:

We promise that we can change or refund products if there are any quality problem.

| 国家: |

China |

| 型号: |

VN-MS1800-U07

|

| 离岸价格: |

4.5 ~ 26.2 / Piece ( Negotiable ) (面議)

获取最新报价

|

| 位置: |

China |

| 最小订单价格: |

4.5 per Piece |

| 最小订单: |

2 Piece |

| 包装细节: |

In exporting wooden case |

| 交货时间: |

3-5days |

| 供应能力: |

30000 Piece per Month |

| 付款方式: |

PayPal, Money Gram, Western Union, D/P, D/A, L/C, T/T |

| 產品組 : |

MoSi2 heating element

|