详情

our company have

built more than *0 years, have passed ISO***1:***0 and we main

produce block machine(semi &full automatic ) and AAC block

machine(light weight block machine).

select our

company is your best selection.

Detailed Product

Description

1) Germany

Technology plant

2) ISO ***1:***0

3) Free one year

warranty.

4) Free

training

5) Send

engineers to install machines

1)

introduction

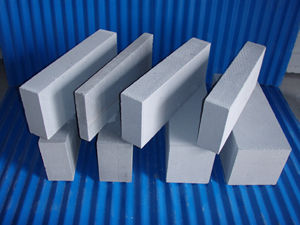

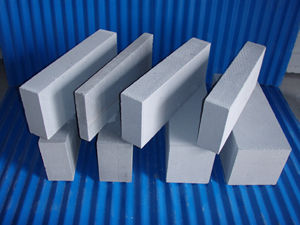

Areated concrete block

(light block ) is the light and porous building material. It has

light keeping temperature cant burn and other advantages. it can

be made into many kinds of bricks for

example:**0×**0×**0,*0×*0×**0,**0×**5×*3,**0×**0×**5),they could

be used industry building and common building. they are more and

more popular in the world in the future, they will replace the

Clay brick completely.

2) Areated concrete

common conception

Common concrete

density is usually ********0kg/m3,but Areated concrete are

**0kg/m3,**0kg/m3,**0kg/m3.It has not the big grain, main use

silicon material (for example: coal ash, sand, stone dust and

others ),through making the material small for example sand, they

can be used directly if has enough degree of small (for example

coal ash. Mixing calcium material lime cement water to a

special slop, then add the aluminum dust and the additive. Make

the aluminum dust and the special slop have a Chemical reflect.

then produce Hydrogen to make the concrete slop to expanding or

swell, foam. Next, put them into the curing room to concreting

cutting steaming curing, last, there will become the light brick,

the porous rate is ****0%.

3)

Advantages

a) light weight

,Areated concrete density is usually ******0kg/m3,(according the

market in produce ),same as 1/3 of clay block and 1/5

common concrete. So use the Light block can reduce the weight of

the build more, and also reduce the beam of roof and pillar

press best. then you can see ,it can save the material and cost,

it also fighting shaking.

b) keeping temperature

It has many are porous, the delivery hearting coefficient is

0.**0.*2W/(mk),the same as 1/4 or 1/5 of clay brick, so it

is best materials now in the world.

have many kinds

material, have lowest waste

Main Material: coal

ash sand waste mine material coal stone dust and other silicon

materials.

1) Product weight is

according to **0kg/m3 to control.

2) annual

capacity **0,**0M3.

3) set raw

material proportion: cement 6.5%, raw lime *3%, fly ash *8%,

gypsum 3%, aluminum paste powder **0g/M3.

4) water and

material rate 0.**1

5) one mould

product 2.*8M3

6) Casting slurry

cycle time **6 minutes, cut cycle time 5

minutes.

7) casting slurry

temperature ****2 degree

8) body quiet stop.

Time is 1.**2.5housr, temperature ****0 degree, after quiet stop

body strength is 0.***0.*8Mpa

9) Steam curing

cycle time, come in and out autoclave about 0.5hour, steam curing

cycle time about is 6 hours/1.6Mpa, total 6.5

hours.

*0) Cement lime

fly ash style aerated block raw material

proportion

| 国家: |

China |

| 型号: |

BD-3001

|

| 离岸价格: |

(面議)

获取最新报价

|

| 位置: |

Wuhan, Hubei province, China |

| 最小订单价格: |

- |

| 最小订单: |

1 Set |

| 包装细节: |

nude packing |

| 交货时间: |

45-60 days |

| 供应能力: |

3 Set per Month |

| 付款方式: |

T/T, L/C, Western Union |

| 產品組 : |

AAC block production plant

|