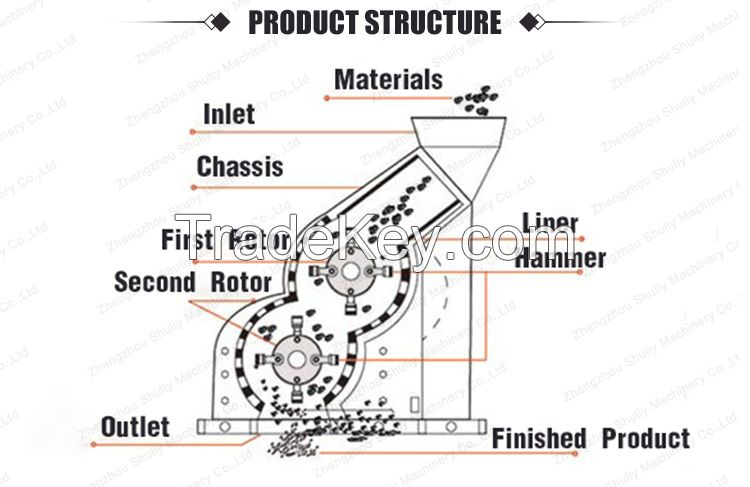

The hammer crusher mainly relies on impact energy to complete the

crushing operation of materials. When working, the motor drives the

rotor to rotate at a high speed, and the material enters the

crusher cavity evenly, The high-speed rotating hammer impacts,

shears, and tears the material, causing the material to be broken.

The head rushes to the baffle plate and sieve bar in the frame, and

the material larger than the sieve hole size is retained on the

sieve plate and continues to be hit and ground by the hammer until

it is crushed to the required discharge particle size, and then

discharged out of the machine through the sieve plate.

|

Model

|

Input Size (mm)

|

Output Size (mm)

|

Capacity(t/h)

|

motor ratio(kw)

|

Dimensions(m)

|

Weight(t)

|

|

SL200*300

|

< =100

|

< =10

|

3-5

|

7.5

|

0.8*0.5*0.8

|

0.5

|

|

SL400*300

|

< =100

|

< =10

|

5-10

|

11

|

0.9*0.6*0.8

|

0.8

|

|

SL600*400

|

< =120

|

< =15

|

10-25

|

18.5

|

1.2*1.05*1.2

|

1.5

|

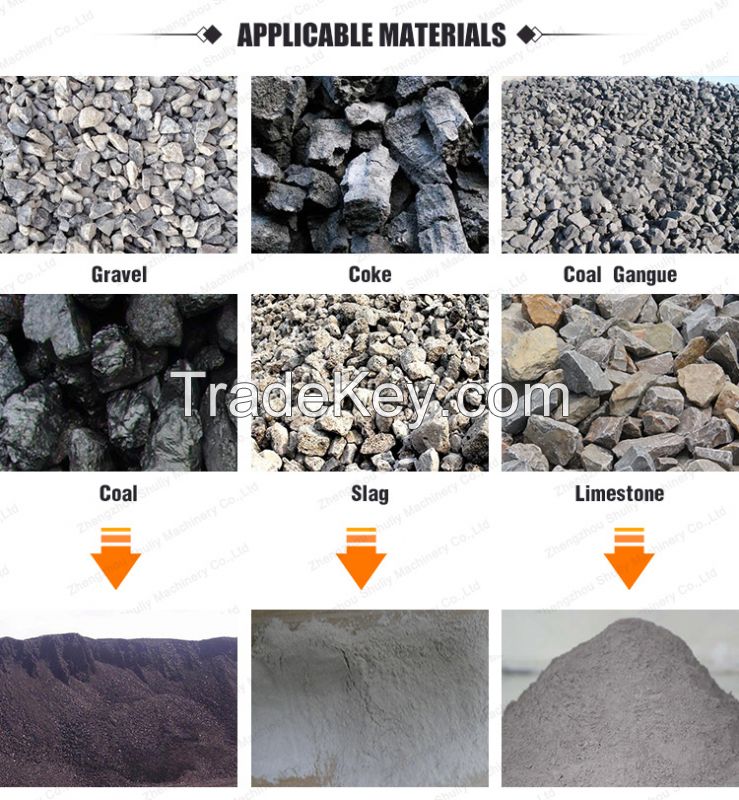

Advantage

The hammer crusher is used for crushing all kinds of medium-hard

and weakly abrasive materials. The compressive strength of the

materials does not exceed 100MPa, and the moisture content is

less than 15%. The crushed materials are coal, salt, chalk,

gypsum, bricks, limestone, etc. It is also used for crushing

fibrous structures, broken wood with strong elasticity and

toughness, paper or crushed asbestos cement waste to recover

asbestos fibers, and so on.

Feature

Features of Hammer Crusher:

1. The overall design has a beautiful appearance, compact

structure, fewer wearing parts, and convenient maintenance. It

is an upgraded product.

2. The crushing ratio is large, generally 10-25, and the

highest is 50.

3. The crushing equipment has a high degree of automation, a

large crushing ratio, and high production efficiency. The

crushed product is in the shape of a cube, with low needle-like

content, no internal cracks, and high compressive

strength.

4. The hammerhead is cast with new technology, which has high

wear resistance and impact resistance.

5. The body structure of the hammer crusher is sealed, which

solves the problem of dust pollution and dust leakage in the

crushing workshop.

6. High production capacity, good grain shape of finished

product, low energy consumption per unit product.

7. Product granularity can be flexibly adjusted according to

user needs.