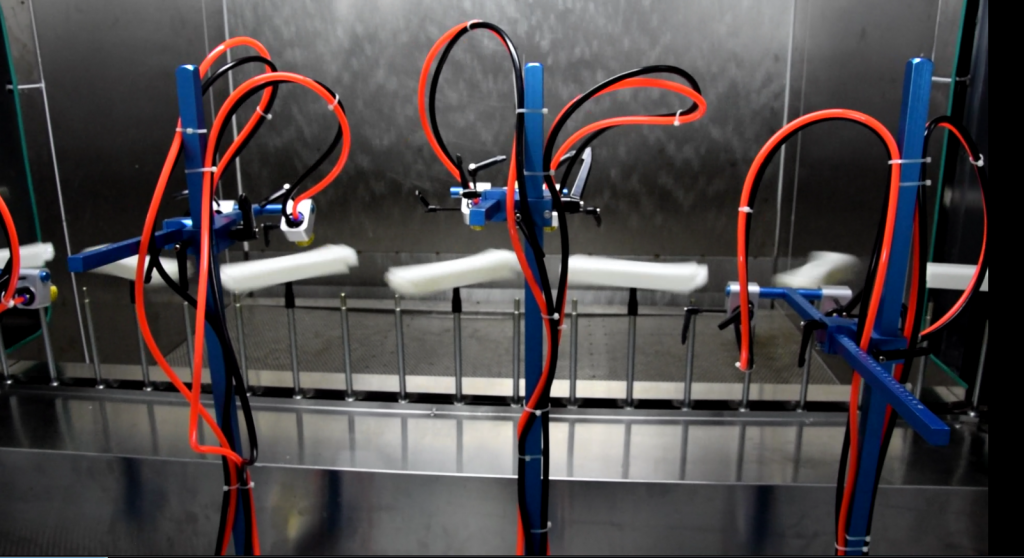

automatic spray coating line can be setup in

different coating purpose such as single layer, two and three

layers plus UV curing etc. It can be also setup for specific paint

spraying such as rubber paint, water based paint and PU

etc.

Spray coating line workflow: Load ->

electrostatic de-dust -> automatic spraying -> drying

(process can be replicated for multi layers

coating)

Coating line setup parameters:

Conveyor speed: 0-8 m/min.

Rotation speed: 10-200 r/min.

Spray gun:2-12pcs

Spray method: gun fixed conveyor or reciprocator

or robotic spraying

Spray booth: water or dry filter based booth with

detectable fresh air supply.

Oven: sandwitch board chamber with in flared

heater, SRC control

Control: PLC and touch screen programming control,

trace on conveyor automatic spraying for paint

saving.

Advantages: fast spraying and smooth film

thickness. Spray at different angles by only one time

configuration.

How is uv coating

applied?

UV

is always the final process on painting line structure. There're

base and top coat to be sprayed before UV. The purpose of UV is to

provide smooth feel and clear light on

surface.

What kind of product is

suitable for uv coating?

Any product which requires clear light surface

effect.

What do I need aware

during operation?

We

will send out technicians for onsite installation and provide up to

30 days training service till you can operate the system

properly.

What're the spare parts

for uv coating line?

Heating pipes, UV lamps and filters should be

checked regularly and replace in time in case any

problem.

How much time for

producing?

This depends the overall line size and customer

requirements. Normally it takes 30~60 days

produci

| 国家: | China |

| 型号: | Model |

| 离岸价格: | ( Negotiable ) 获取最新报价 |

| 位置: | china |

| 最小订单价格: | - |

| 最小订单: | 1 Set |

| 包装细节: | set |

| 交货时间: | 10 |

| 供应能力: | - |

| 付款方式: | T/T |

| 產品組 : | - |