详情

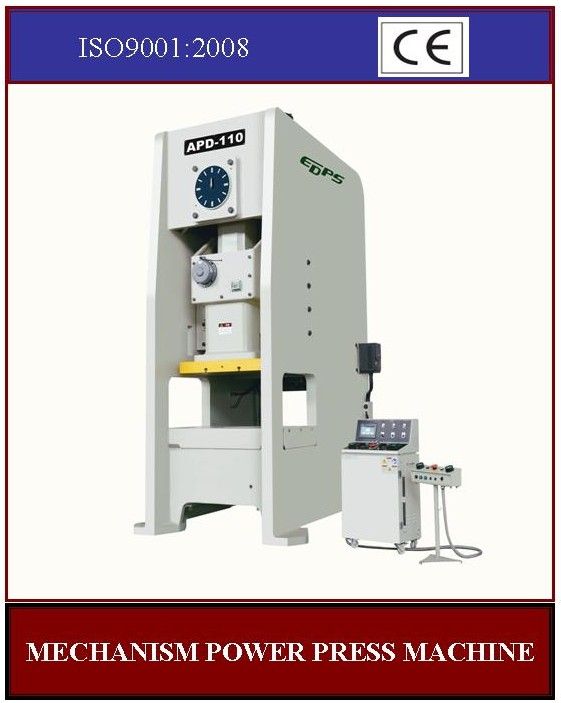

Straight side frame designed virtually eliminates angular

deflection, providing increased precision for progressive die

applications and reducing maintenace costs on tooling.

No inherent angular deflection, which significantly exlends die

life and reduces cost of tooling maintenance.

It's patented high-torque wet clutch and brake system provides low

noise, long life operation with minimal maintenance.

The slide area is *5%**5%, greater than comparable c-frame presses

to allow for larger tools. The large *-point gibs are centered in

the slide body, to provide betterresistance to off center

loads.

High torque, enclosed wet clutch brake unit requires minimal

maintenance, eliminates noise and pollution caused by air borne

particles, and significantly extends lining life.

Ues friendly multifunctional control system.

Designed to allow simple integration with automated auxiliary

equipments.

Standard Accessories

Inverter

Hydraulic over-load protector

Slide adjust device

Die height indicator

Blance device

Rotary Cam switch

Crank angle indicator

Electrical stroke counter

Air source receptacle

Against over-run safety device

Maintenance tool box

Operation manual

Optional Accessories

Electrical automatic lubrication system

Pneumatic die cushion device

Preset counter

Preset counter

Foot switch

Quick die change device(Die lifter, clamp&die arem sepjes)

Slide knoce-out device

Misfeed detection consent

Power supply

Auti-vibration press mount

Photo-ELECTRONIC SAFETY DEVICE

Feeder

Uncoiler

Leveler

Mechanism hand

Die room light

Left(right)feeding device

PAC **0counter system

Human-computer counter system