详情

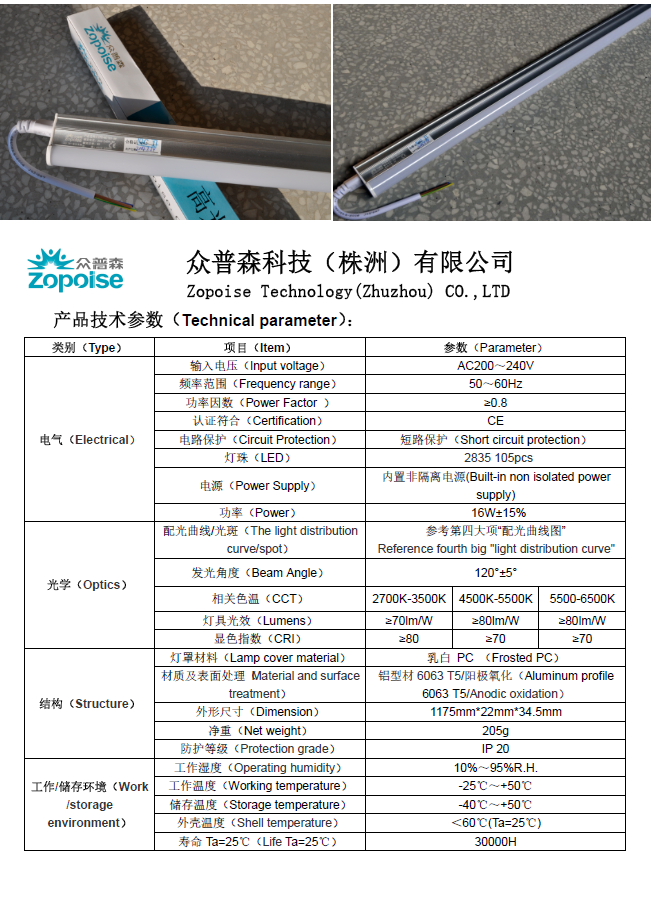

Zopoise LED T5 integrated lighting fixture on sale

ZPS-MD*****6W

Please contact for more details.

There are a lot suppliers offering different rating LED light tubes

with different prices.

Actually there are real differences in the price forming. Here Id

like to have brief explanation about it.

- LED light source. Prices differ in the types, and in the

brands. The different LED light sources have distinguishing

performances in brightness, heat dissipation, light uniformity,

lumens depreciation, stability, life span etc.

- Mounting methods for LED light source. To produce a

specified power light tube, manufacturers can use different types

LED light sources and those will cost different times for

welding/mounting.

For example, #***8 LED chip has rate power of 0.***5W driven by low

current under *0mA. However, #***4 LED chip has rate power of 0.1W

driven by *0mA current. If a final rated *8W light tube is needed,

it will cost **8pcs #***8 chip, and the labor cost will be

calculated as **8times welding/mounting. As to #***4, the

corresponding data will be **0pcs and **0times. As a result,

different prices derives from this part light source and labor

cost.

- The driver. Light tube with external driver has longer life

span than that with internal driver because of performance in heat

dissipation. But External driver is more expensive and people need

to revise the circuit when replace CFL tube. So most LED light

tubes in the market are equipped with internal driver.

There are isolated & non-isolated ones when we talk about

internal driver. Isolated driver has a compared security guaranteed

design but a little more expensive. Some suppliers may adopt

non-isolated driver to reduce the cost, but put buyers in the risk

of electric shock because of its simple and rough design.

Meanwhile, the drivers price differs due to materials and

manufacturing process.

- The construct and proximate matters. All-plastic

tube was mainly adopted in early period. It has very poor

performance in heat dissipation and this will easily lead to lumens

depreciation. Afterwards the half-plastic-half-aluminum tube came

into use. The aluminum material should have enough thickness to be

qualified for heat dissipation. Some suppliers may use thin

aluminum material with a lot impurities at low cost.

- Other aspects. Different lampshades have different light

transmittance. Aluminum substrates is various. Bolts fastening is

better than glue fastening. Other factors influencing the life

times etc.