离岸价格

获取最新报价0.595 ~ 0.64 / Metric Ton

|Minimum Order

位置:

-

最小订单价格:

最小订单:

500 Kilogram

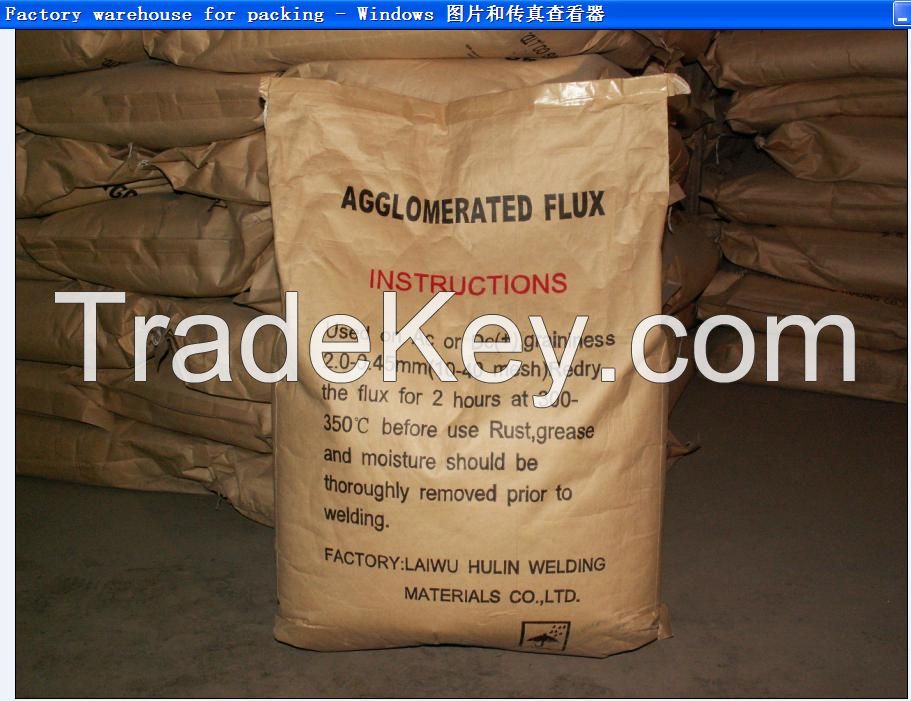

包装细节:

plastic and paper bag 25KGs/Bag;

交货时间:

15 days

供应能力:

2000 Metric Ton per Month

付款方式:

T/T

联系人 Mr. MARTIN

1#,North Guanxi Road,xintianzhai, Guiyang, Guizhou

|

Item Content |

Si2O+TiO2 |

CaO+MgO |

Al2O3+MnO |

CaF2 |

S |

P |

| Tested results | *8 - *5 | *8 *5 | *3 - *0 | *6 - *5 | ≤0.**3 | ≤0.**1 |

|

Combination With welding wire type |

Yield strength σs (MPa) |

Tensile Strength (σb)(Mpa) |

Elongation (δs)% |

Akv ( J )冲击功 (Below zero ℃ ) |

|

| - *0℃ | - *0℃ | ||||

| H*0Mn2A | ≥**0 | ≥**0 | ≥*2 | ≥**0 J | ≥ **2 |

| TESTED | **2 | **6 | *9 | **8 | **5 |