离岸价格

获取最新报价( Negotiable )

|Minimum Order

位置:

-

最小订单价格:

-

最小订单:

1 Unit

包装细节:

Large part is non-packed, small part is in wood case.

交货时间:

10-30 days

供应能力:

1000 Unit per Month

付款方式:

T/T, L/C

Algeria

联系人 Mr. Brahim

Economical Zone, Ghardaia, Other

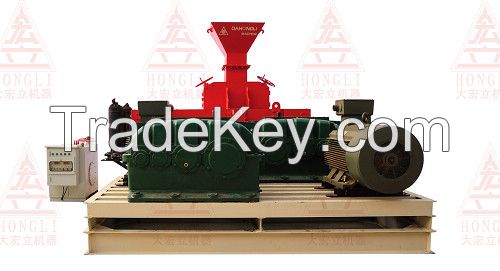

Product Characteristics:

1. The hydraulic system makes it easy to adjust the roller crevice while protecting the machine.

2. The roller and its surface are

fitted with hard alloy studs that increase its service life by

2000-20000 hours.

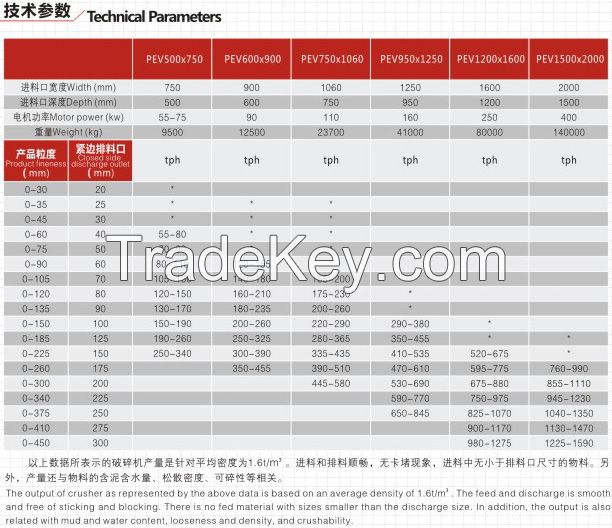

Technical Parameters:

|

Model |

Motor power(Kw) |

Feed size (mm) |

Discharge fineness (mm)< 5mm |

Throughput ( m3/H ) |

Power supply voltage |

|

DHLG75×20 |

2×(55-75) |

30 |

50-70% |

25-40 |

380V |

|

DHLG75×27 |

2×(90-132) |

30 |

50-70% |

45-60 |

380V |

|

DHLG75×50 |

2×(160-200) |

30 |

50-70% |

80-110 |

380V |

|

DHLG140×40 |

2×(250-280) |

40 |

50-70% |

75-100 |

380V |

|

DHLG140×65 |

2×500 |

40 |

50-70% |

145-200 |

6KV-10KV |

|

DHLG140×80 |

2×560 |

40 |

50-70% |

170-225 |

6KV-10KV |

|

DHLG170×100 |

2×800 |

50 |

50-70% |

240-315 |

6KV-10KV |

|

DHLG200×120 |

2×1600 |

60 |

50-70% |

525-950 |

6KV-10KV |