详情

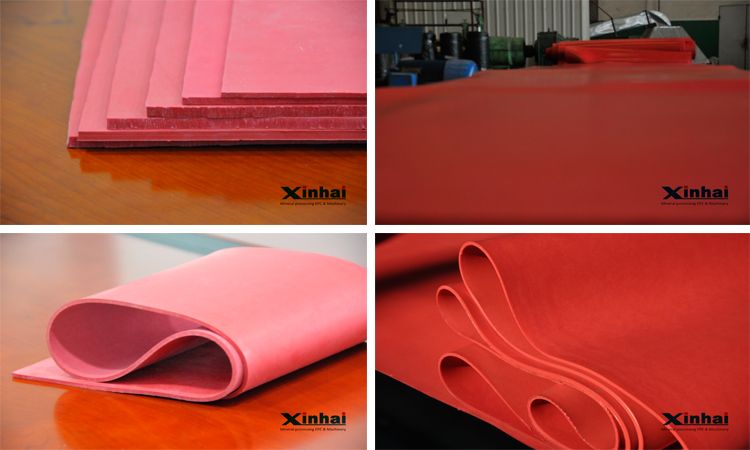

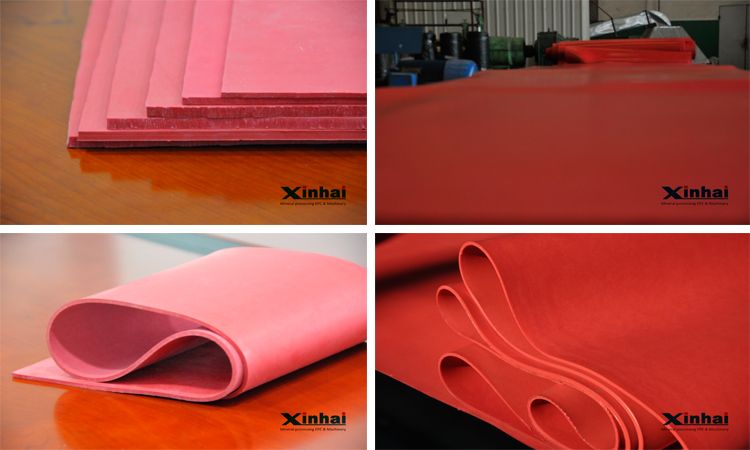

Product Introduction

Domestic unique rubber sheet used in wet condition

Working Pressure

Pressure ≤1.0MPa

Product Improvement

Wear resistant Rubber Sheet adopts the technology (Liquid phase

nanometer compounding-normal temperature high frequency curing) by

Xinhai independently developed

Product Feature

Creative technology reserves the molecular chain of natural rubber.

The content of natural rubber reaches 97%; uniform rubber

vulcanization, strong comprehensive performance.

Tests show that Xinhai Wear - Resistant Rubber sheet owns excellent

performance :

Wear resistance index 128%

Resilience 80%

Tensile strength 23.5MP

Tearing strength 168N/mm

Advantages

I Softkill of Xinhai Wear-Resistant Rubber

Xinhai wear-resistant rubber has a large amount of polymer long

chains. It has such characters as strong tensile resistance and

high resilience, which effectively improves the performance of wear

and corrosion resistance. Compared with ordinary rubbers, Xinhai

rubber reduces the microstructure damage to the lowest, and

maintains the natural features of solid, good elasticity and

wear-resistance.

Xinhai Wear resistant rubber with high elasticity is different from

the hard materials such as cast stone, compounding ceramics, alloy,

iron, etc. It can effectively absorb and repulse the impact and

friction force, which takes the loss to a minimum, the noise to the

lowest, showing the characteristics of softkill.

II Resistance to wear and corrosion

The wear resistance index of Xinhai Wear resistant Rubber sheet

reaches 128%. 1 mm wear experiment shows that Xinhai Wear

resistant Rubber which takes 100 hours to wear 1 mm wins out over

the other kinds of rubber which takes 13.8 hour and 24 hour

respectively to wear 1 mm.

III The service life is longer than other rubber by 2-4 times

Because of the excellent performance of Xinhai rubber (Tensile

strength, wear and corrosion resistance), its service life is

longer than other rubber by 2-4 times

IV Flexible and convenient cutting, wide application

Cutting and bonding the wear resistant rubber to meet various shape

and surface requirements, according to the need of piping, pipe

fittings, hopper, chute, cylinder, and so on.

Technical Parameters

|

Rubber types |

35 |

40 |

50 |

60 |

HD62 |

HD70 |

HDS |

N55 |

|

Color |

Red |

Red |

Red / Orange |

Red / Orange |

Black |

Black |

Red |

Orange |

|

Polymer type |

Nature |

Nature |

Nature |

Nature |

Natural / Synthetic |

Natural / Synthetic |

Natural / Synthetic |

NBR(Nitrile rubber) |

|

Items |

Standard |

|

|

|

|

|

|

|

|

|

Hardness |

GB/T6031-1998 |

35 |

39 |

50 |

60 |

62 |

70 |

70 |

55 |

|

Tensile strength (MPa) |

GB/T528-1998 |

23.5 |

25 |

29 |

28 |

22 |

23 |

22.8 |

19 |

|

Elongation at break % |

GB/T528-1998 |

866 |

750 |

750 |

750 |

700 |

600 |

580 |

740 |

|

Tension set % |

GB/T528-1998 |

4 |

6 |

20 |

40 |

12 |

14 |

25 |

12 |

|

Tear strength (N/mm) |

GB/T529-1998 |

81.34 |

80 |

140 |

168 |

136 |

142 |

100 |

71 |

|

Resilience % |

GB/T1681-1991 |

76 |

74 |

68 |

56 |

50 |

44 |

57 |

34 |

|

Specific gravity |

GB/T533-1991 |

0.95 |

0.95 |

1.06 |

1.1 |

1.12 |

1.14 |

1.14 |

1.14 |

|

Temperature range |

|

-40 - 70oC |

-40 - 70oC |

-40 - 70oC |

-40 - 75oC |

-40 - 75oC |

-40 - 75oC |

-40 - 75oC |

-40 - 110oC |

|

Wear resistance index |

GB/T9867-1988

Wet |

>=128% |

>=90% |

>=40% |

>=20% |

>=40% |

>=40% |

>=38% |

>=16% |