Sizes in

supply

**0.*5, **0.5, **1, 0.**1, 0.**1.5, **2,**3, **3, **3, **4, *-

6, **8, ***0, ***2, ***4, ***6, ****0, ****2, ****5, ****0, ****6,

****0, ****5, ****0 Micron

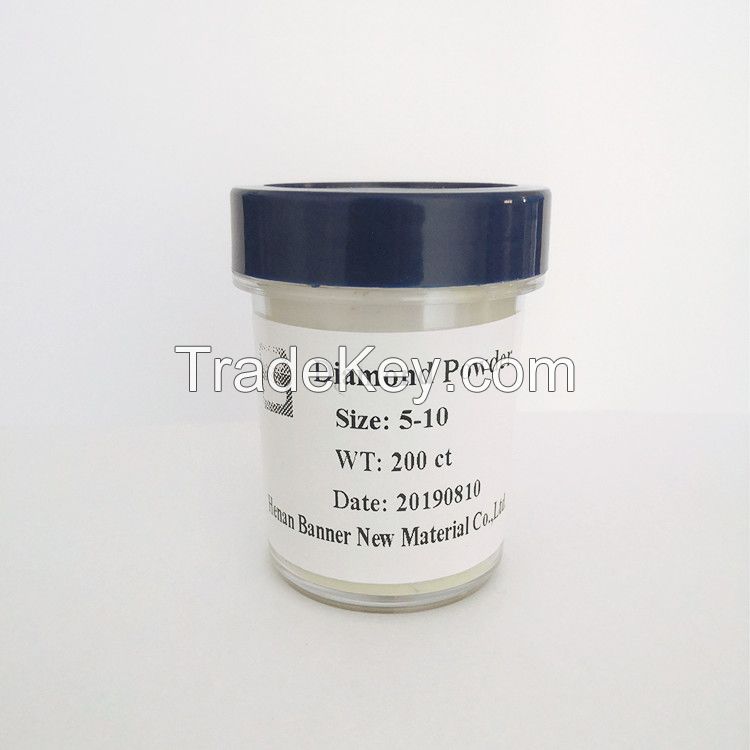

Micron diamond

powder is kind of diamond particles within size of *6/*4 micron,

with high hardness and good wear resistance. As one of

the new super hard superfine abrasives, it was widely used in

cutting, grinding, drilling and polishing

etc..

About Our

Diamond Powder

1.

Selected domestic high-grade single crystal diamond raw materials,

static pressure strength, wear resistance and thermal stability are

better than industry standards.

2.

The crystal is round, and the adsorption force on the surface of

the particles is small. There are no needle-rod or sheet-like

particles.

3.

Very narrow particle size distribution range, excellent particle

size control.

4.

After special treatment, the impurity content is reduced to the

order of one hundred thousand.

5.

Suitable for precision instruments and other industries with high

requirements for grinding and polishing, as well as for the

production of electroplating, diamond composite sheets, and other

areas with strict requirements for impurity

content.

Unique Selling Points of

Diamond Powder

1. Shape. There are various shapes while

the synthetic diamond formed, such as round shape, block

shape, flake shape, long strips shape and bar shape. Block

shape is the best, round shape is better. Cause while

grinding, other three shapes may scratch the

item.

2. Grain Size. Full sizes of

International Standard. Customized is

acceptable.

3. Controllable. All of our products are

strictly controlled before marketing.

1) Every single size of diamond abrasive

produced in an independent container;

2) Feeding of material is

uniform;

3) For detection, to measure the size by

microscope firstly, then to judge if it is qualified by laser

particle size analyzer;

4) Independent workshop for

packaging.

4. Impurity. Remove the impurity after

shaping. Acid treatment - Washing - Storing, if necessary or

required by customer, alkali treatment will be

made.

5. Crushing of diamond. Airflow crushing

and Ball crushing.