离岸价格

获取最新报价( Negotiable )

|Minimum Order

位置:

-

最小订单价格:

-

最小订单:

1 Set

包装细节:

As requested

交货时间:

As the model selected

供应能力:

1 Set per Month

付款方式:

T/T, L/C

联系人 Mr. Guanglei

Kaifadong 26 road, Shenyang, Liaoning

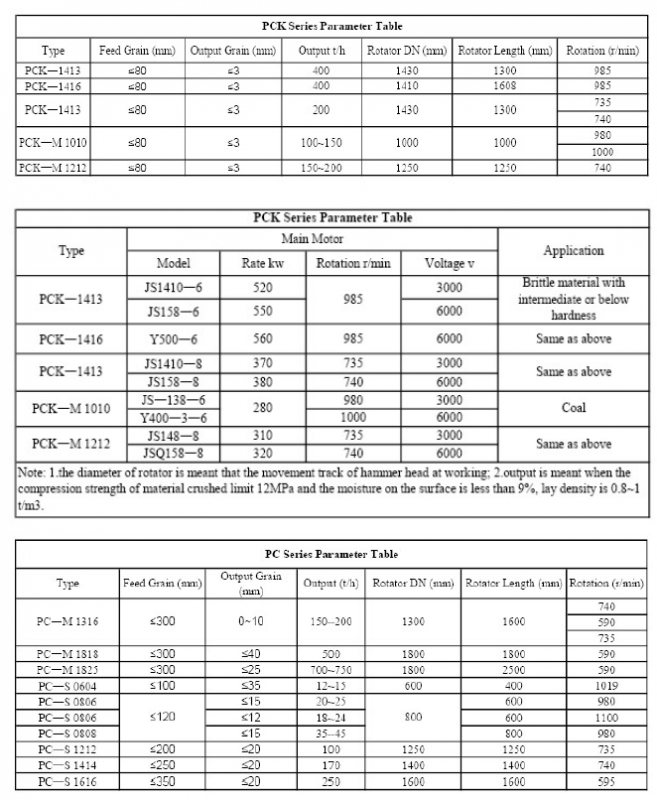

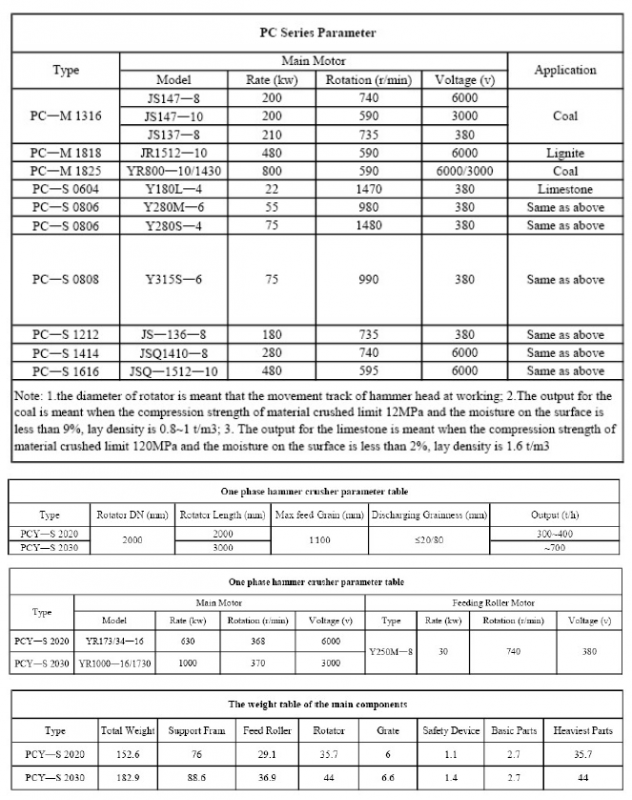

The hammer crusher with the feature of big crushing ratio, high production and uniform granularity is one of main machine for fine crushing limestone, coal or other brittle materials with medium or below medium hardness which is used in the industries of metallurgy, building material, chemical works and hydropower. One-phase hammer crusher can crush the material fed from granularity of 1100mm into 20mm or below at a time so that the traditional crusher with two-phases or three phases will be substituted this kind of one-phase so as to simplify the technique and save the investment on machine and also reduce the manufacturing cost.

The hammer crusher can be classified as reversible type or irreversible type wherein the reversible hammer crusher has reversible rotator which is generally used in fine crushing and the irreversible hammer crusher has the irreversible rotator which is generally used in intermediate crushing. One-phase hammer crusher is irreversible type.

The ordinary hammer crusher is mainly composed of support frame, rotator, sieve, impact plate and regulator. The motor drives the rotator through the coupling to run at high speed, the ore fed is impacted by the hammer installed on the rotator and broken into small piece, from which the ore crushed obtain the kinetic energy and rush at high speed to the impact plate and sieve inside the support frame, concurrently the impact also happens between mutual ores to reach the crushing many times. If the size of ore crushed is less than the sieve pore those will be discharged but some big ones will be impacted, squeezed and grinded by the hammer so as to be crushed again and be extruded out through the sieve pore by the hammer.