离岸价格

获取最新报价( Negotiable )

|Minimum Order

位置:

-

最小订单价格:

-

最小订单:

1 Set

包装细节:

As requested

交货时间:

As the model selected

供应能力:

1 Set per Month

付款方式:

T/T, L/C

联系人 Mr. Guanglei

Kaifadong 26 road, Shenyang, Liaoning

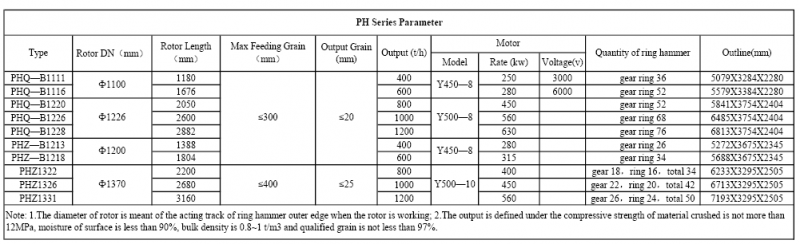

In order to meet the requirements for crushing coal in the thermal power plant, our company has been introduced of the technology of ring hammer crusher from Pennsylvania Crusher Company in the United States, and with which we practice our rich experience in designing and manufacturing hammer crusher and counter-impact crusher to research and develop the two series of light type and heavy type of 10 specifications ring hammer crusher whose design and manufacture are completely localized.

This kind of crusher has not only high-speed rotating ring hammer hitting materials and collision between materials but also the function of extrusion and grinding. The crusher can crush material fed into the more uniform particles under the effect of the above functions and also has a strong discharging capacity.

To compare with hammer crusher and counter-impact crusher, ring hammer crusher has the advantages of high efficiency, energy saving, stable operation, low noise and small blowing volume, and which is widely used in crushing coal in thermal power plants.

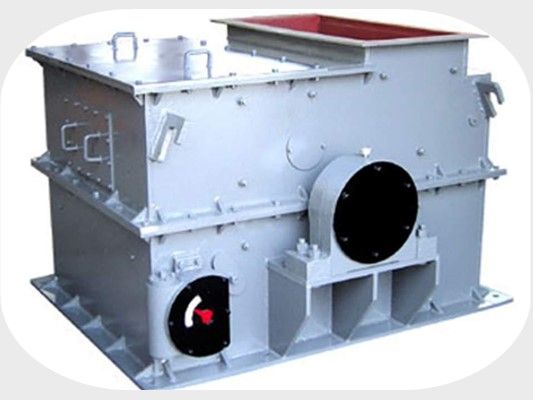

The ring-hammer crusher is mainly composed of frame, rotor, grate plate, synchronous regulator, upper-cover hydraulic opening device and other parts. The crusher is directly started by the elastic steel plate coupling connecting with the motor.

The frame part is mainly composed of the lower frame, the upper cover and the bypass groove. The upper cover can be opened by hydraulic pressure to repair and replace the fragile parts and equipped with a non-fragmentable materials collection cabinet used for collecting non-fragmentable materials under the force of the centrifugal force of the ring hammer, which protects not only the crusher itself but also the next step working machine.

The bypass groove can be arranged to directly deliver fine coal that is not crushed to the next working procedure without passing through the crusher thus it can save power consumption. If the system is not required the bypass groove it can not be selected.

Installation of this crusher can be directed to left or right. To face the front of the crusher i.e. feeding groove or bypass groove location motor is installed in the right side the crusher is right, otherwise it is left.