详情

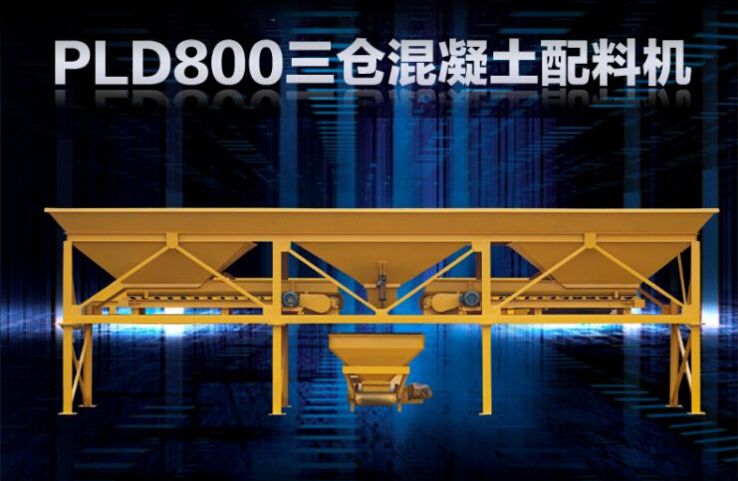

PLDD**0 concrete batching machine

Introduction:

PLD**0 concrete batching machine is a batching equipment for

loading with loader or belt conveyor. The weighing bucket has a

capacity of **0 liters and a large weighing value of 2T. It can be

equipped with 2 or 3 kinds of materials. The equipment uses

imported weighing induction sensor, which has good performance and

fast and accurate weighing. The overall design is reasonable and

the conveying is stable. It is a worthy choice in concrete batching

equipment.

Product advantages:

1. High weighing accuracy

The core components are all imported from foreign brands, with high

precision, fast efficiency and stable performance.

2. Microcomputer control

Automatically complete the batching of various materials according

to the user-defined ratio, accurate and fast

3. Easy to operate

PLD**0 concrete batching machine is designed according to the

technical standard of batching system in GB****2 "Technical

Conditions of Concrete Mixing Station", which is easy to operate

and can be operated by one button.

4. Multiple combinations

This series of concrete batching machine combined with the

corresponding concrete mixer can form a combination mixing station

of different forms and specifications, which is the ideal equipment

for on-site production of high quality concrete.

Product parameters:

|

Name |

PLDD**0 concrete batching machine |

|

Type |

PLD**0 two-silo |

PLD**0 three-silo |

|

Weighing hopper capacity |

0.8 m³ |

0.8 m³ |

|

Storage hopper capacity |

3.2 m³ × 2 |

3.2 m³ × 3 |

|

Production |

*8 m³/h |

*8 m³/h |

|

Batching precision |

±2% |

±2% |

|

Aggregates available |

2 |

3 |

|

Feeding height |

2.*4 m |

2.*4 m |

|

Power |

*2 kw |

*6 kw |

|

Dimension(LxWxH) |

6.2m×1.9m×2.*4m |

9.*3m×1.9m×2.*4m |

|

Overall Weight |

***0 kg |

***5 kg |

Maintenance method:

In the daily use of PLD**0 concrete batching machine, some common

faults can be manually eliminated by the user, as follows:

1. There is control over control or malfunction during the

batching

Cause: A There is a source of interference near the A power supply

or the batcher. Measures: Turn off the batching machine control

unit and restart it, and place the easily disturbed electric

appliances such as electric welding machines far away from the

batching machine.

Cause: B voltage is unstable, too high or too low. Action: Add a

pressurizer to the batcher control unit.

Cause: C The batch controller is too hot. Measures: Increase the

shading facilities.

2. Weighing is not allowed

Cause: A fixing bolt between the weighing system and the frame is

not removed. Action: Remove the bolt.

Cause: B System error. Action: Adjust the lever system.

Cause: C sensor drift error. Action: Make a reset.

Cause: The D sensor is damaged. Action: Replace the sensor.

3. Some materials are not ingredients

Cause: The motor wiring is loose; the high-voltage control part of

the AC contactor is faulty. Action: Check the electrical control

circuit to troubleshoot.

4. Endless conveyor belt deviation

Cause: The main and passive roller axes are not parallel. Action:

Adjust tighten the bolt.

5. Batching device failure

Refer to the relevant provisions of the "Ingredient Controller

Manual".