No. 5, North Mingxin Road, Gangkou Industrial Park, Ningguo Economoc and Technological Development ,Ningguo,Ahui,China China

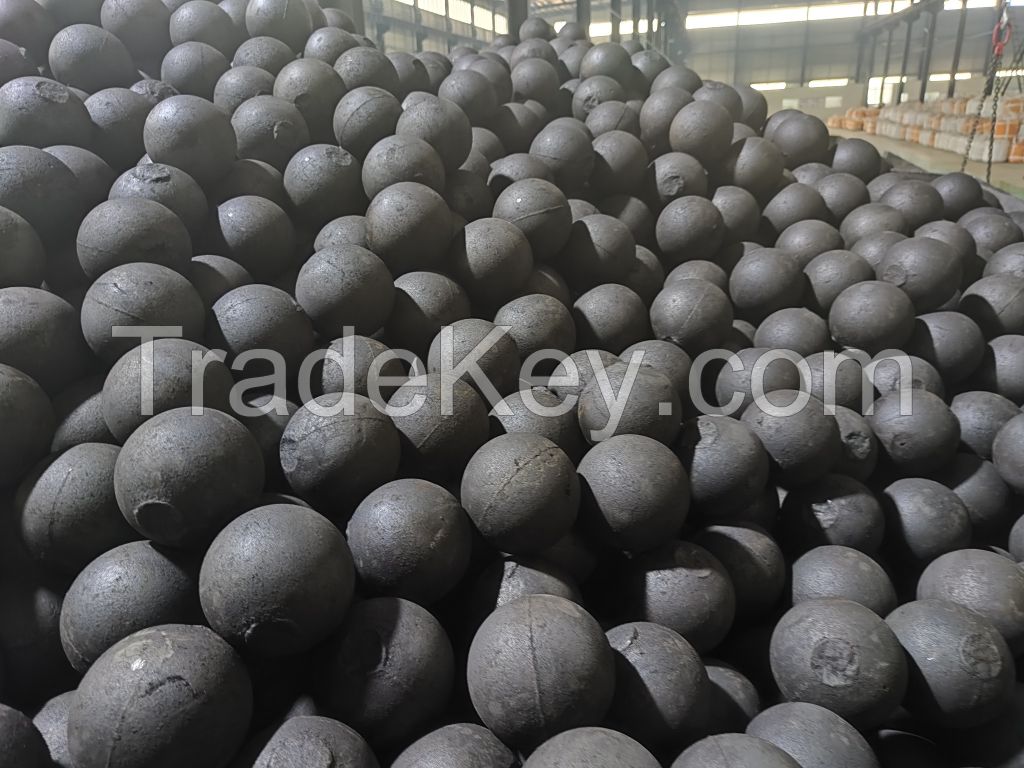

Anhui Sanfang New Material

Technology Co., Ltd is located in Ningguo City, Anhui

Province, P.R.China, which is the biggest wear-resistant materials

production base, the city of wear-resistant casting parts, the foot

of Huangshan Mountain. The company was established in 2013, with

high chrome cast grinding balls as our main products, annually

80,000 tons production and 650 million CNY turnover. Now we are the

biggest exporter of cast grinding balls in

China.

Our

newest product is high chrome casting grinding ball, which is

widely used in cement, mining and thermal power, exported to

Australia, Congo, Malaysia, Brazil and Colombia. Most of our

customers are mining companies, such as CITIC Pacific Mining,

Karara Mining, Zijin Mining, KAMOA Copper SA, Tenke Fungurume

Mining SA, La Miniere De Kalukundi SA, La Compagnie Miniere De

Kambove SA and Continental Gold Colombia.

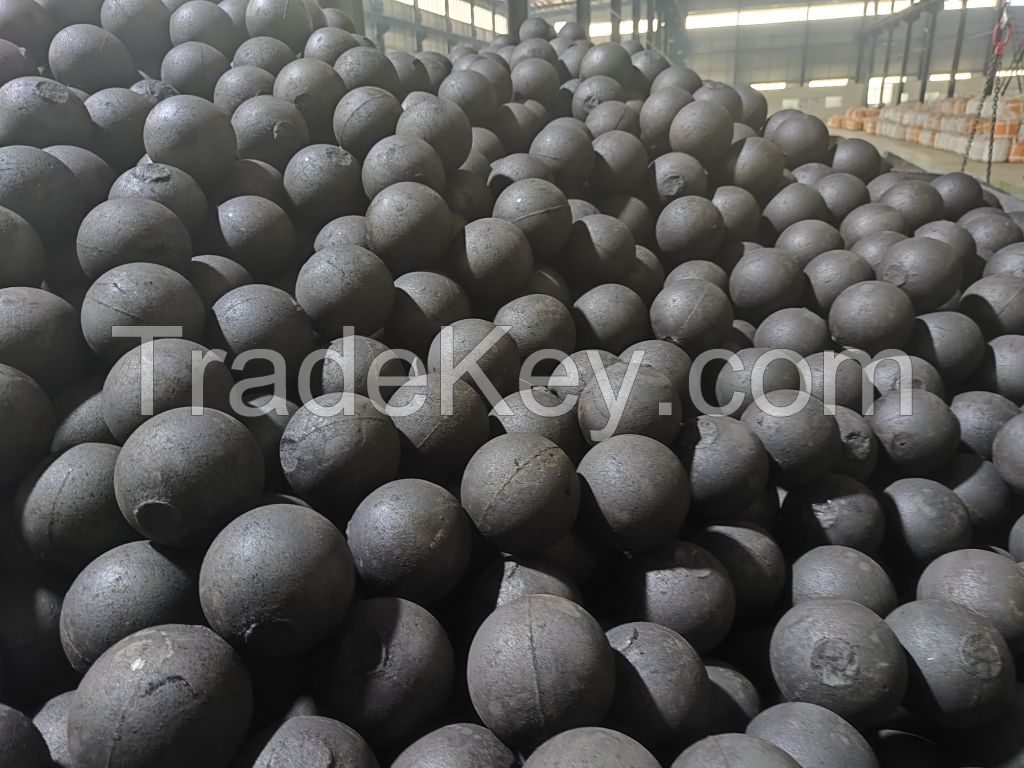

We

have three casting lines, one of them is horizontal parting

flaskless shoot squeeze mould production line, for the casting of

grinding balls diameter less than 40mm. And the other two are sand

coated iron mould production lines, for the casting of grinding

balls diameter bigger than 40mm, which cooling speed after been

casted is higher than sand moulds. It is just like been quenched

once casted, so the microstructure is tighter and the deformed rate

is lower than our competitors.

And

also we have two continuous heat treatment (quenching + tempering)

production lines, one is mesh belt, for grinding balls diameter

less than 50mm, the other is roller hearth, for grinding balls

diameter bigger than 50mm. The heat treatment production lines

ensure the grinding balls are heated enough before quenched, so the

hardness of the grinding balls are more even, and hardness

deviation between surface and core are less than

1HRC.

The

company has passed

the certificates of ISO9001:2015 (Quality

Management System), ISO14001:2015 (Environmental

Management System) and GB/T45001-2020 (Occupational

Health &Safety

Management System)

high chrome cast grinding balls

high chrome cast grinding balls

high chrome cast grinding balls Cr15-17%

high chrome cast grinding balls Cr15-17%

high chrome cast grinding balls Cr10-12%

high chrome cast grinding balls Cr10-12%

high chrome cast grinding balls Cr17%min

high chrome cast grinding balls Cr17%min

high chrome cast grinding balls Cr12%min

high chrome cast grinding balls Cr12%min

high chrome cast grinding balls Cr15%min

high chrome cast grinding balls Cr15%min

high chrome cast grinding balls Cr10%min

high chrome cast grinding balls Cr10%min

high chrome cast grinding balls Cr28%min

high chrome cast grinding balls Cr28%min

high chrome cast grinding balls Cr18%min

high chrome cast grinding balls Cr18%min

high chrome cast grinding balls Cr18-20%

high chrome cast grinding balls Cr18-20%

high chrome cast grinding balls Cr12-14%

high chrome cast grinding balls Cr12-14%

high chrome cast grinding balls Cr17-19%

high chrome cast grinding balls Cr17-19%

| 企业类型 | Manufacturing |

| 网站 | http://www.ahsanfang.com.cn |

| 建立年份 | 2013 |

| 公司雇员数量 | 101-500 |

| 主要市场 | Worldwide |

| 产品/服务 | grinding media, grinding balls, grinding cylpebs, high chrome cast grinding balls, high chrome cast grinding cylpebs |

| 工厂位置 | Ningguo, China |

| 厂房面积 | 250000 sqm to 500000 sqm |

| 生产线号 | 5 |

| 年总购买量 | 50 - 100 Million USD |

| R&D人员数 | 11 - 20 people |

| 质量控制 | In House |

| 证明 | ISO9001:2000 |

| 合同制造 | N/A |

| 注册资本 | 2.5 - 10 Million USD |

| 所有权类型 | Corporation Limited Liability Company |

| 法人代表/执行总裁 | Ming Yang |

| 出口比例 | 90 |

| 年营业额 | 50 - 100 Million USD |

| 质检人数 | 6 - 10 people |

| 联系人 | Mr. Ted |

| 公司名称 | Anhui Sanfang New Material Technology Co., Ltd. |

| 电话号码 | ******** |

| 移动电话 | ******** |

| 传真号码 | ******** |