Hangzhou,Zhejiang,China China

2.5Kg Twin Tub Washing Machine

2.5Kg Twin Tub Washing Machine

3.175*22, two flutes spiral carbide cnc router bits, for Acylic, PVC, MDF

3.175*22, two flutes spiral carbide cnc router bits, for Acylic, PVC, MDF

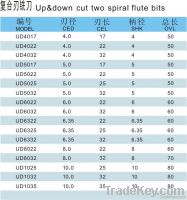

6*22*60 , up&down(left&right spiral) two spiral composite flute bits, cn

6*22*60 , up&down(left&right spiral) two spiral composite flute bits, cn

AC custom-made washing machine motor/wash motor

AC custom-made washing machine motor/wash motor

AC dehydration washing machine motor/washing machine parts

AC dehydration washing machine motor/washing machine parts

AC washing machine motor/wash motor

AC washing machine motor/wash motor

AC XD washing machine motor/washing machine parts

AC XD washing machine motor/washing machine parts

Agriculture chain

Agriculture chain

Air conditioner outdoor fan motors

Air conditioner outdoor fan motors

Aluminium CNC parts

Aluminium CNC parts

Cold forming can be advantageous in the manufacturing of micro medical parts due to the need for long MTBF cycles that are often imperative, and because cold formed medical parts are stronger than most other manufacturing methods. In addition, other superior quality aspects are built-in since the process is inherently free of burrs, smudges, and contamination. A high-polish surface finish can be produced as part of the manufacturing process for applications involving medical components used for implantation. Additionally, there is no need to run cold formed parts through acid baths in order to pass cytotoxic testing.

We provide medical manufacturing that supports our customers with high-speed product ramp-up, delivery, and the ability to manage volume regardless of complexity or product mix. In addition to our state-of-the-art machining capabilities and expert engineering and manufacturing support, we also offer design, prototyping, and tooling support.

现在联系| 企业类型 | Manufacturing |

| 网站 | N/A |

| 建立年份 | 1987 |

| 公司雇员数量 | 51-100 |

| 主要市场 | Americas,Asia,America,Middle East,Worldwide |

| 产品/服务 | micro parts, micro sized parts, miniature titanium alloy parts, miniature parts, micro machined parts machining, miniature parts machining |

| 工厂位置 | N/A |

| 厂房面积 | N/A |

| 生产线号 | 0 |

| 年总购买量 | N/A |

| R&D人员数 | N/A |

| 质量控制 | N/A |

| 证明 | N/A |

| 合同制造 | N/A |

| 注册资本 | N/A |

| 所有权类型 | N/A |

| 法人代表/执行总裁 | N/A |

| 出口比例 | N/A |

| 年营业额 | N/A |

| 质检人数 | N/A |

| 联系人 | daisy |

| 公司名称 | Hangzhou Micro Parts Co., Ltd |

| 电话号码 | ******** |

| 移动电话 | ******** |

| 传真号码 | ******** |