Products descripion

Characteristics of UV flatbed printer

To most of the clients, non-UV printers are flatbed printers. At

present, eco-solvent inks are generally used in printing. If too

many prints apply eco-solvent inks, the material quality would be

deteriorated, and the adhesiveness would be poor and need coating.

Eco-solvent inks need to dry in the air because they are not easily

dried, but can easily converge in winter. The advantage of

eco-solvent inks is that their colors are better and brighter than

UV inks.

UV printer: The inks dry as soon as they are printed. Most of the

inks do not need to be coated, which spares a step in the process.

Their adhesiveness are relatively stronger and do not weaken

easily, but their colors are darker than eco-solvent inks, because

UV inks dry as soon as they are printed, which is a very short

time. The environment-friendly UV inks meet the needs of most

productions and are the mainstream development trend in present

day.

FAQs about *0 malfunctions of the universal UV flatbed printer

1. The universal UV flatbed printer prints out blank papers

In the case of universal dot matrix flatbed printer, the reasons

that the papers printed out blank mostly are dry ink ribbon, broken

ink ribbon, damaged print head, etc. The solution is to change the

ribbon or repair the print head in time. In the case of universal

inkjet flatbed printer, the malfunction of blank prints is mainly

due to jammed nozzle, empty ink cartridge, etc. The solution is to

clean the nozzle or change the ink cartridge. In the case of

universal laser flatbed printer, this kind of malfunction is

probably caused by a developing roller without toner (a developing

roller without DC bias); an ungrounded photosensitive drum that

blocks the negative charges from reaching the ground; a laser beam

that shows no effect on photosensitive drum a protective cover for

selenium drum or s laser scan that is not open, etc.

If the photosensitive drum of universal laser flatbed printer does

not rotate, there will be no image generated and printed out on

paper. Cut off he printers power source and take out the toner

cartridge, open the selenium drums (toner cartridge) protective

cover, leave a gel pen mark on the non-photosensitive parts at both

ends of the photosensitive drum before installing it back to the

printer. Open the printer to warm-up for a while, take out the

toner cartridge and see if the marker have moved (to check whether

the photosensitive drum is working properly). If the self-test

papers are printed out blank, it should be checked that has the

printer run out of toner, has the toner cartridge been installed

properly, has the sealing tape been drawn out, has the laser scan

cover been opened or blocked by foreign matters.

2. The papers printed out black

In the case of dot matrix printer, the reason of this malfunction

can be ribbon depilation; overmuch ribbon ink; smudged print head;

poor ribbon quality; the push rod that is too close, etc. First the

position of push rod should be adjusted during repair. If the

printer still malfunctions, change the ribbon and clean the print

head normally work. In the case of inkjet printer, the focus should

be on checking if the print head is damaged, if the ink tube is

cracked, if the ink type is normal, if the ink pipeline is jammed,

etc. In the case of laser printer, malfunctions are mostly caused

by ineffective corona wire, or malfunctioning control circuit,

selenium drums poor PCR conduction or neglected installation,

making the laser fire all the time, OPC voltage unable to be

discharged or charged, papers printed out black. Therefore, it

should be checked that if the corona wire is disconnected, if the

corona voltage is charged, if the beam detector in the laser beam

access is working properly, if the selenium drums PCR is

uninstalled.

3. Texts printed out incomplete or indistinct

In the case of universal inkjet flatbed printer, there may be two

types of reasons: the toners are used up, or the printer has not

been used for a long time, or the direct sunlight has dried the ink

and jammed the nozzle. The printer needs to change a new cartridge

or be injected with inks. If the cartridge is not used up or the

nozzle is confirmed jammed, detach the nozzle and sink it in warm

water for a while, prick it with a needle or shake it very hard. Be

careful, do not sink its circuit board in the water, so as to avoid

burning the printer.

In the case of universal dot matrix flatbed printer, this

malfunction may be caused by overuse of printer ribbon; a print

head that has not been cleaned for a long time; too much filth in

the printer; pins broken inside print head; the print driver

circuit malfunctions. The solution is to, first, adjust the

distance between print head and print roller, if this malfunction

still exists, try change a new ribbon. If it still does not work,

you need to clean the print head. Cleaning method: remove 2 fixed

screws on the print head, take out the print head, clean the filth

on the print head with pins or hooks. And the filth are usually

ribbon fibers accumulated in a long time. Then, drip some

instrument oil on the back of the print head where you can see the

pins, so as to clean off the filth. Print some blank self-test

pages without installing the ribbon, then put back the ribbon. This

way the problem can be solved. If this malfunction is caused by

pins broken inside the print head or driver circuit, all you can do

is change pins or driver tube.

In the case of universal laser flatbed printer, this malfunction

may be caused by aging consumable parts; OPC/MR/PCR overuse or

serious wear; TOER deterioration or contamination. Try change or

renew toner cartridge. If the printers driver is incorrect or

incompatible, or if the printer prints gibberish, etc. You can

solve the problem by changing the data line or socket, closing the

computer and printer before restarting them.

4. The printer prints faint texts

In the case of universal dot matrix printer, this malfunction is

mostly caused by dry ink ribbon; pins broken inside print head; a

push rod too far positioned. The solution is to change ribbon and

adjust push rod. In case of inkjet printer, this malfunction can be

caused by jammed nozzle; dry ink; incorrect ink type; air in the

ink tube; overhigh printer operation temperature. The solution is

to test and repair the nozzle, ink cartridge and other parts. In

the case of laser printer, faint texts may occur when the toner

cartridge has too less toners; developing rollers developing

voltage is low; toner has poor photosensitivity. The solution is to

take out the toner cartridge and shake it lightly. If the print

effect is still not improved, you should change the toner cartridge

or adjust the set of photosensitive switches below toner

cartridge.

5. Texts printed out clear on one side and blurry on another

side

This malfunction usually occurs in the case of dot matrix printer.

It can also occur in the case of inkjet printer, but the

possibility is low. The main reason of this malfunction is print

heads guide rail and print roller being unparallel, and the gap

between them are sometimes small and sometimes big. The solution is

to adjust the distance between print heads guide rail and print

roller. Method: unscrew the adjustment flaps on both sides of the

print heads guide rail, twirl the flaps counterclockwise in order

to shorten the distance, then adjust print heads guide rail and

print roller to the level that they are parallel. Note that if the

direction is right during adjustment, you can adjust them gradually

after you print some texts and see the quality. This malfunction

rarely occurs in the case of laser printer, and when occurs, it is

usually caused by misplaced toner cartridge during changing, or the

selenium drum that slightly blocks the scanning system. The

solution is to change the parts. It is also possible that this

malfunction is caused by DB/MR.

现在联系

*China Noteworthy Manufacturer of Large Format Solvent Printer*

*China Noteworthy Manufacturer of Large Format Solvent Printer*

*Lucky Cat Color Banner Inkjet Printer*

*Lucky Cat Color Banner Inkjet Printer*

*Up to 50% OFF China's Favourite UV Flat Bed Printer*

*Up to 50% OFF China's Favourite UV Flat Bed Printer*

1.25-14P-5800-Bdata cable

1.25-14P-5800-Bdata cable

3.2m Crystaljet CJ4000 SPT 510/35pl large format printer

3.2m Crystaljet CJ4000 SPT 510/35pl large format printer

3.2m Crystaljet CJ6000 large format printer

3.2m Crystaljet CJ6000 large format printer

3.2m Konica 512/14pl large format printer

3.2m Konica 512/14pl large format printer

3.2m konica large format prinet (konica 512/14pl printhead, 1440dpi)

3.2m konica large format prinet (konica 512/14pl printhead, 1440dpi)

5300 series

5300 series

6800 series

6800 series

Hot Sell Multi Function Purpose Printer

Hot Sell Multi Function Purpose Printer

High On Efficiency Flatbed Printer

High On Efficiency Flatbed Printer

Multi Function Printer For Printing Phone Cases

Multi Function Printer For Printing Phone Cases

Industrial Printer For Customized T Shirt Printing

Industrial Printer For Customized T Shirt Printing

Multi Function And Usage Business Printer

Multi Function And Usage Business Printer

Multi Function And Purpose Industrial Printer

Multi Function And Purpose Industrial Printer

Highly Specialized Industrial Printer

Highly Specialized Industrial Printer

Best Design Piezo Industrial Printer

Best Design Piezo Industrial Printer

Ultraviolet Function Flatbed Printer

Ultraviolet Function Flatbed Printer

Mass Production Multi Function Printer

Mass Production Multi Function Printer

Multi-function printer

Multi-function printer

Multi-function printer

Multi-function printer

Multi-function printer

Multi-function printer

Soft facial tissue automatic packaging machine

Soft facial tissue automatic packaging machine

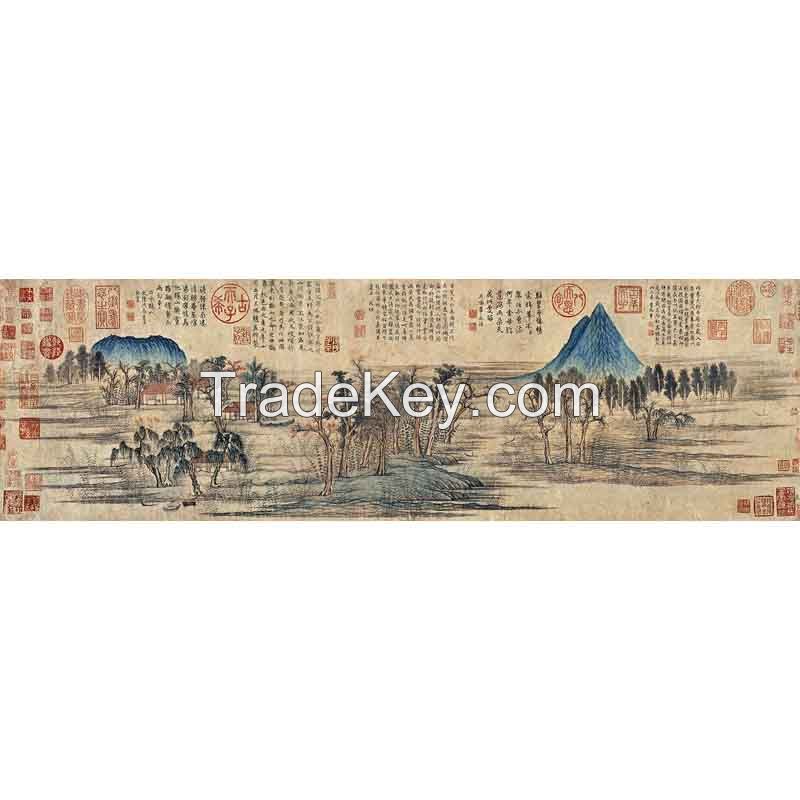

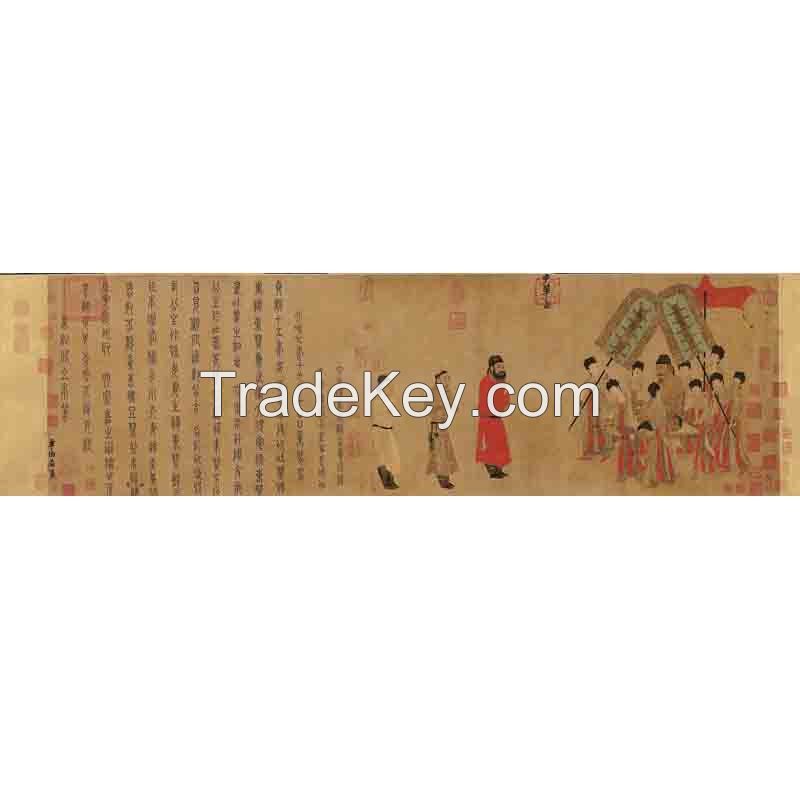

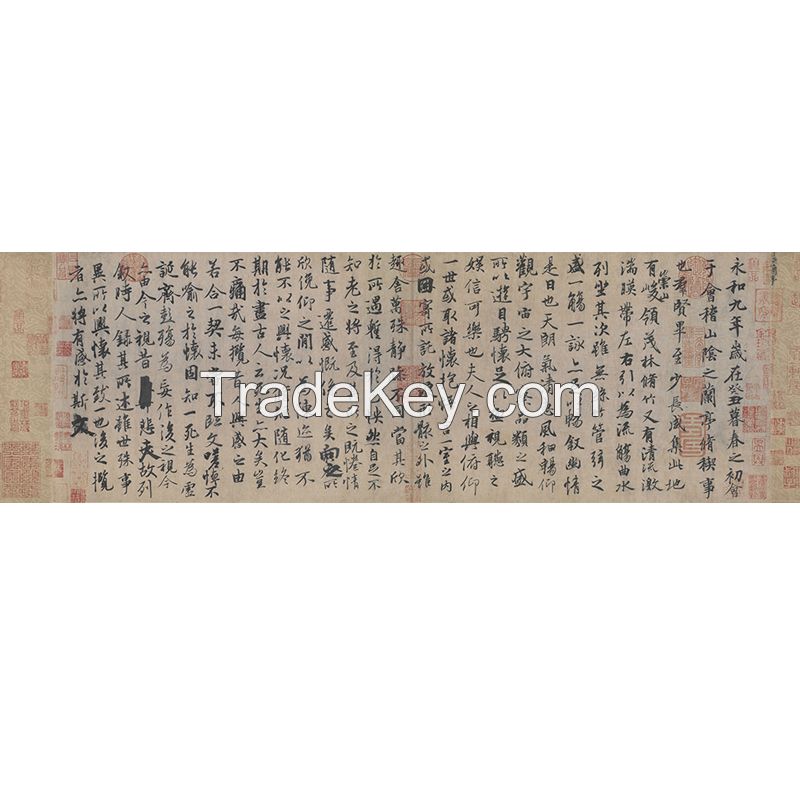

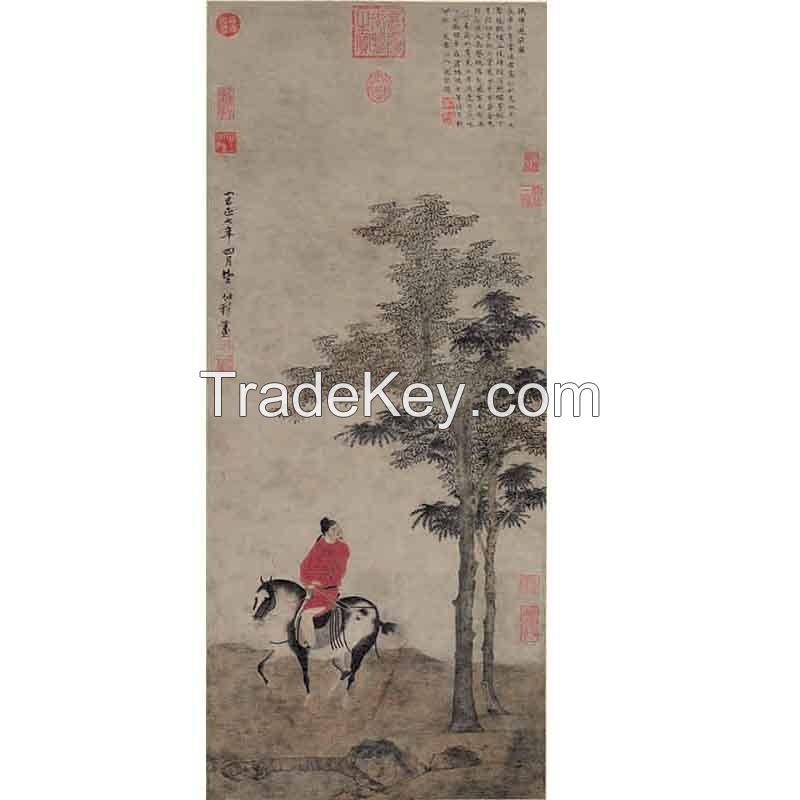

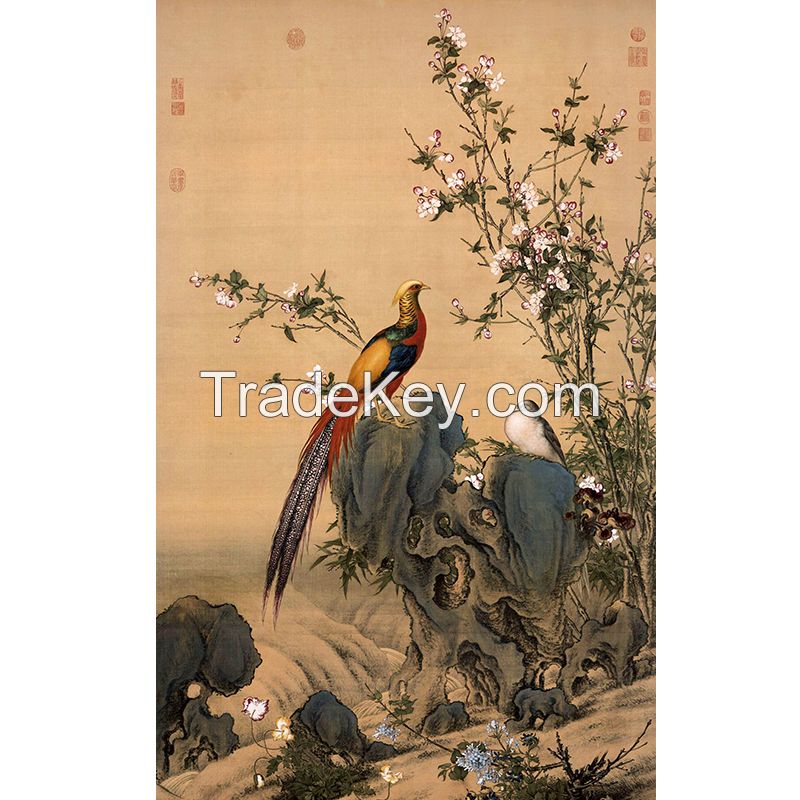

Famous Chinese painting in Chinese imperial palace

Famous Chinese painting in Chinese imperial palace

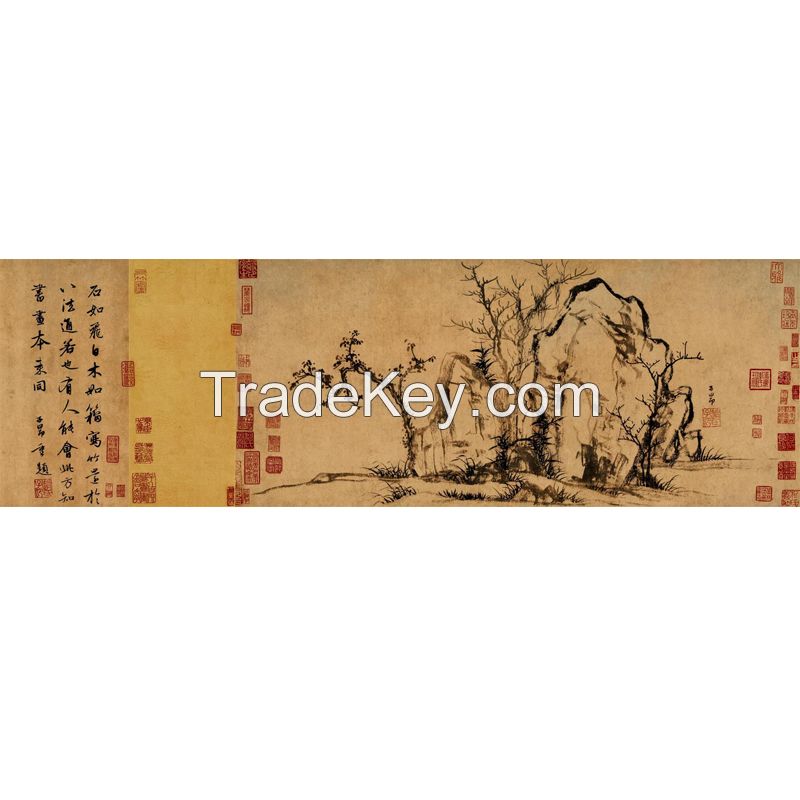

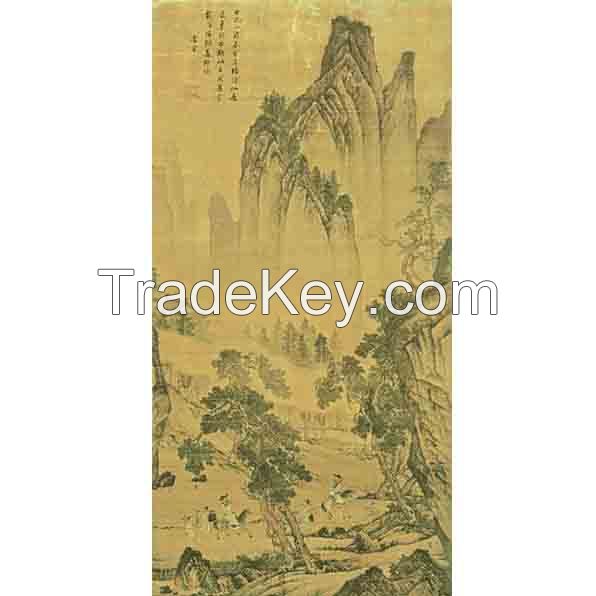

Traditional Chinese painting in Chinese imperial palace

Traditional Chinese painting in Chinese imperial palace

Traditional Chinese painting in Chinese imperial palace

Traditional Chinese painting in Chinese imperial palace

Famous Chinese painting in Chinese imperial palace

Famous Chinese painting in Chinese imperial palace

Famous Chinese painting in Chinese imperial palace

Famous Chinese painting in Chinese imperial palace

Famous Chinese painting in Chinese imperial palace

Famous Chinese painting in Chinese imperial palace

Printer

Printer

Flatbed printer

Flatbed printer

Flatbed printer

Flatbed printer

Printer

Printer

Printer

Printer

Printer

Printer

Printer

Printer

Printer

Printer

Printer

Printer