Gaoqiao Industrial Area,,Ningbo,Zhejiang,China China

FRP PULTRUDED MOULDS

FRP PULTRUDED MOULDS

P20 FRP PULTRUDED MOULDS

P20 FRP PULTRUDED MOULDS

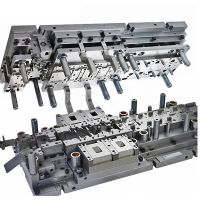

1-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Auto part molds

1-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Auto part molds

10-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

10-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

11-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

11-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

12-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

12-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

13-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

13-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

14-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

14-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Electronics prat molds

15-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Mobility part molds

15-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Mobility part molds

16-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Mobility part molds

16-ISO/IATF Precision Mold, Precision Mould, Stamping Mold, Stamping Die, Metal Mold, Die Maker, Manufacture Mold, Forming Mold, Precision Die, Mold Maker, Forming Die, Manufacture Die, Mobility part molds

KEKO Prototyping use various rapid prototyping technologies and material to produce the best visual rapid prototypes in the industry.Service include: rapid prototyping, SLA, SLS, CNC machining, 3D CAD Design Services, high quality Silicone mould and vacuum casting, rapid cnc milling, urethane castings, Reverse Engineering, custom molds, all sorts of plastic mold and aluminium die casting mould making, production tooling. we have helped numerous customers succeed at getting their rapid prototyping and product development projects completed on time. Product design: From a simple sketch or idea to the final product, KEKO team contains designers can assist you in the early stages of product development Rapid prototyping: We make use of the different prototyping techniques including: SLA, SLS, CNC machining and urethane castings. We always keeping one goal in mind. That goal is to make rapid prototyping easy for our users. Custom molds, plastic molds, die-casting molds: Our engineers can design and custom-make all types of plastic molds and die-casting molds based off detailed customers sketches and ideas. Production tooling: Our own production factory have more than ten sets different specifications of injection molding machines£die-casting machine and mold manufacturing equipment. We have an outstanding capacity to meet the requirements of high-volume suppliers. Sheet metal prototype: We simplify sheet metal fabrication projects for low-high volume, high quality production. Our sheet metal fabrication services, ranging from precision CNC bending, CNC punching, laser cutting, MIG, TIG & spot welding, fastener insertion and product assembly. Urethane casting: Our vacuum cast urethane parts created from RTV silicone rubber molds. Vacuum cast urethane parts are cast in silicone rubber molds and provide an economical and fast way to simulate injection molded plastic parts without the cost or time delay of hard tooling. Metal parts machining :We prov

现在联系| 企业类型 | Manufacturing |

| 网站 | http://www.china-rapid-prototyping.com |

| 建立年份 | 2000 |

| 公司雇员数量 | 51-100 |

| 主要市场 | Americas,America,Europe,North Europe,West Europe |

| 产品/服务 | china rapid prototyping, cnc rapid prototypes, sla, sls, sheet metal prototype, urethane castings, silicone mould, aluminum rapid prototyping, selective laser sintering |

| 工厂位置 | N/A |

| 厂房面积 | N/A |

| 生产线号 | 0 |

| 年总购买量 | N/A |

| R&D人员数 | N/A |

| 质量控制 | N/A |

| 证明 | N/A |

| 合同制造 | N/A |

| 注册资本 | N/A |

| 所有权类型 | N/A |

| 法人代表/执行总裁 | N/A |

| 出口比例 | N/A |

| 年营业额 | N/A |

| 质检人数 | N/A |

| 联系人 | Mr. kekoprototyping |

| 公司名称 | Ningbo Keko prototyping Inc. |

| 电话号码 | ******** |

| 移动电话 | ******** |

| 传真号码 | ******** |