离岸价格

获取最新报价( Negotiable )

|1 Piece Minimum Order

联系人 Levi

Jinan, Shandong

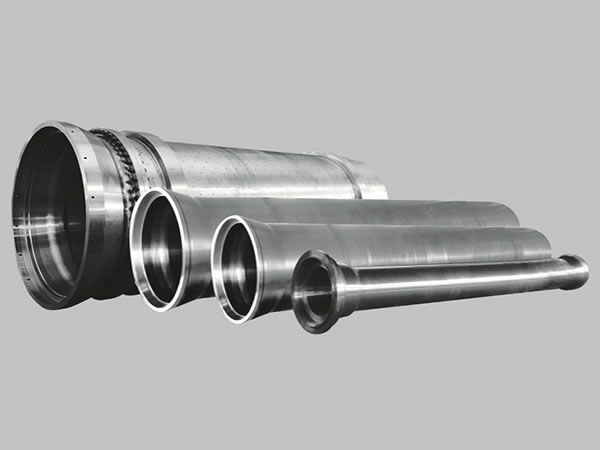

Tong Yu is the largest production

base of ductile iron pipe mould in Asia, Our pipe mould are

available mainly in diameter for DN*0 to DN***0mm, Ductile iron

pipe mould is a compulsory toll in producing ductile iron pipe .It

is rather expensive and its price takes a large proportion in the

product cost of casting pipes. So it is of great significance to

improve the quality of pipe mould and extend their life

.

It has been proven that ,the

performance and service life of our pipe moulds competent with that

of the moulds produced in America and Germany, Tong Yu ductile iron

pipe mould have been applied in various larges casting pipe

manufactures in China ,and exports to many regions like Japan ,and

Southeast Asia.

Clients are required to offer their

drawings and technical requirement, Which will transferred to

technical department(heat treatment center, large forgings research

center, mechanical research center, and welding department, etc,)

for confirmation and accounting, Then we will offer you the

quotation, The ordered products will be put into production as soon

as possible after clients have placed an order. For any

problems rise in the product line, We will contact and

discuss with our clients directly.

Specification of pipe moulds

| Material | *1CrMo*0 |

| Types | Water-cooled metal pipe mould,hot molding |

| Specification | DN******0mm |

| 国家: | China |

| 型号: | DN50-DN2600mm |

| 离岸价格: | ( Negotiable ) 获取最新报价 |

| 位置: | China |

| 最小订单价格: | - |

| 最小订单: | 1 Piece |

| 包装细节: | Wood or Iron frame with plastic outside |

| 交货时间: | 50 days after PO confirm |

| 供应能力: | 5000 Piece per Year |

| 付款方式: | L/C, T/T |

| 產品組 : | Forgings |