详情

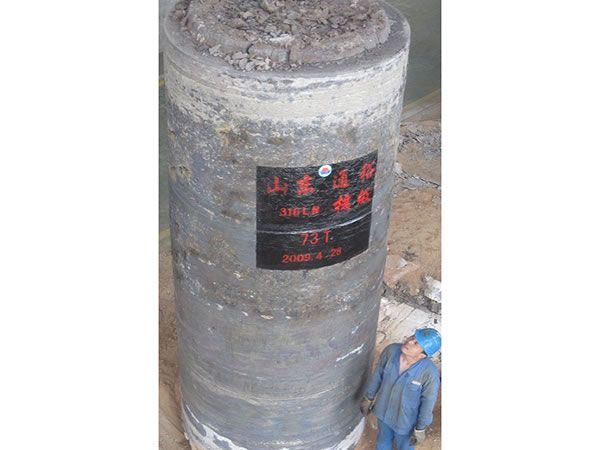

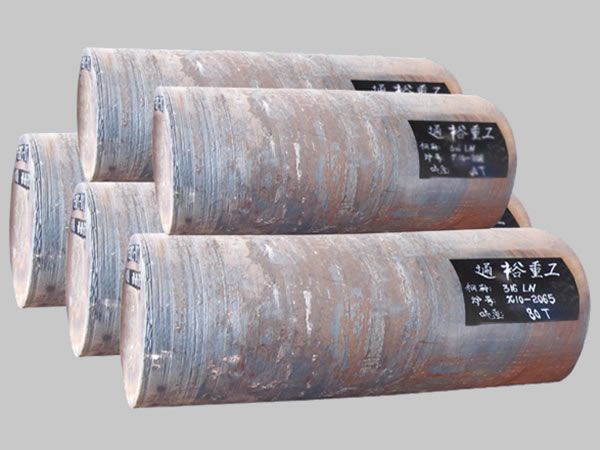

Tongyu has developed *3t AP***0 eletroslag remelting ingot , which

is the 3rd generation of ingot used for nuclear plant

pipeline, Electroslag smelting means melting the consumable

electrode with the resistance heat generated from electricity. The

molten metal will converges into droplets and passes through the

slag pool, then falls into the crystallizer. Under the water

cooling effect, the metal will immediately solidify into steel

ingot .

Clients are required to offer their

drawings and technical requirement, Which will transferred to

technical department(heat treatment center, large forgings research

center, mechanical research center, and welding department, etc,)

for confirmaion and accounting, Then we will offer you the

quotation, The ordered products will be put into production as soon

as possible after clients have placed an order. For any

problems rasied in the product line ,We will contact and disscuss

with our clients directly.

Features of Eletroslag Remelting Ingot

- When the droplets pass through the slag pool

,the non-metallic debris will be absorbed by the slag,

- The harmful elements (S Pb Sb Bi Sn)will be

effectivly removed by the reaction between steel and slag .

- Covered by the slag, the liquid steel is well

protected from oxidation,

- The slag generates a thin layer on the inner

wall of crystallizer ,working both to protect ingot surface and

to insulate against heat or electricity. In this way ,much of the

thermal are transferred downward, ensuring the ingots compactness

and directional crystallization.

Appications

The eletroslag remelting ingots produced by Tongyu are extensively

applied in alloy steel ,steel for rolls, mold steel, Martensitic

stainless steel, Austenitic stainless steel,and steel for nuclear

power ,such as

MC3A,MC5,*6CrMoV7,9Cr2Mo,9Cr3Mo,*0CrNiMoV,*0CrNiMo,5CrNiMo,H*1,H*2

H*3,5CrMnMo,**0,FV**0B,***4,2Cr*3,0Cr*7Ni4Cu4Nb,OCr*3Ni5Mo,**4,**6,**1,**6LN,X2CrNiMo*8.*2,*4CrMo1A,***0H,*4CrNiMo6,*1CrMo*0,*0SiMn2MoVA,*2CrMo,*4CrNi3MoV,*5CrMo

*8CrNiMo**6,*0MnMoNb,*0SiMn,and *7Cr2Ni2Mo,etc.

Smelting Techniques-EAF+LF+VD+ESR

In the EAF+LF+VD smelting technique, the P,S content consumable

eletrode is lower than 0.**8%.

Besides, there is little debris in the raw material, The eletroslag

ingots having been remelted feature high purity,low sulfur

content,little non-matallic debris,smooth surface ,compact

struture,

And uniform chemical components. Their quality and properties can

be modified. Tongyu provides high-quality steel ingots for large

forgings, like steels for nulear power plant, steel for thermal

power and turbine blades ,etc.

| 国家: |

China |

| 型号: |

-

|

| 离岸价格: |

1 ~ 10000 / Ton ( Negotiable ) (面議)

获取最新报价

|

| 位置: |

China |

| 最小订单价格: |

1 per Ton |

| 最小订单: |

1 Piece |

| 包装细节: |

Wood or Iron frame with plastice outside |

| 交货时间: |

30-60 days after PO confirm |

| 供应能力: |

10000 Ton per Year |

| 付款方式: |

T/T, L/C |

| 產品組 : |

Forgings

|