详情

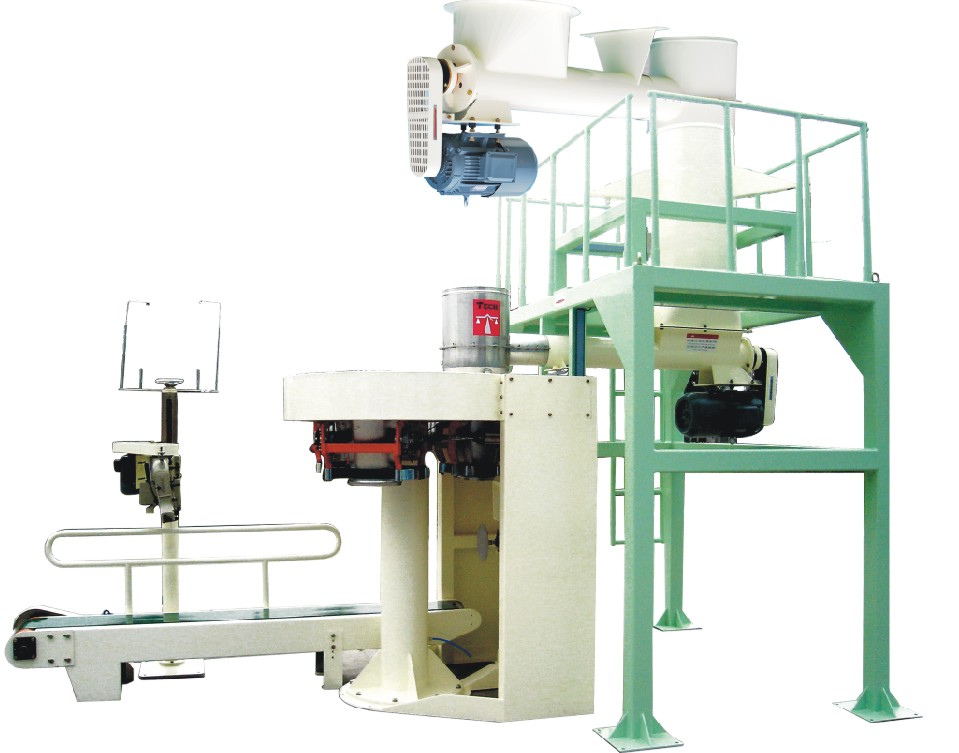

DCS Series Flour

Packer

Principle:

-

The machine comprises a feeding screw conveyor unit, ration

scale, packing clamps unit, shaking unit, bag transferring belt

and automatic sewing machine. The product is fed, scaled, packed,

shaken, sewed and then is transferred for storge.

Features:

- Bag clamp units suitable for *5 kg flour

bag, custom-made type for ****0kg flour bag.

- Tolerance: +/*0.*5%.

- Capacity ******0bags per hour, *5 kg per

bag.

- Feeding hopper, complete with level

detectors.

- Double speed screw feeder suitable for

flour.

- Electronic scale on load cells of HBM

Germany, Supplied with scale control meter F**1 from Japan

UNIPULSE products.

- Discharge gate with pneumatic cylinder

and pneumatic parts from Germany.

- Automatic optimizations of dribble feed

time, automatic reset and weight tolerance adjusting or

correction according to the checking cycle. Possibility of

displaying the actual values on the digital display, simple error

detection indicated through several alarm messages. Memories for

coarse and dribble feed flow selection values.

- Automatic bag release at the throw off

point, with exhaust collection inlet point.

- Bag shaker for compacting the

product.

Application:

- Widely applied in flour mills, feed

mills, and rice mills for final product packing.

- Please feel free to contact us if more

information is needed.