离岸价格

获取最新报价1 ~ 9999 USD / Set ( Negotiable )

|1 Set Minimum Order

国家:

China

型号:

LM Series

离岸价格:

1 ~ 9999 USD / Set ( Negotiable ) 获取最新报价

位置:

Shanghai,China

最小订单价格:

1 per Set

最小订单:

1 Set

包装细节:

Export Standard

交货时间:

30 Days

供应能力:

100 Set per Month

付款方式:

L/C, T/T

联系人 Mr. Saber

416, Jianye RD., Pudong New District, Shanghai, Other

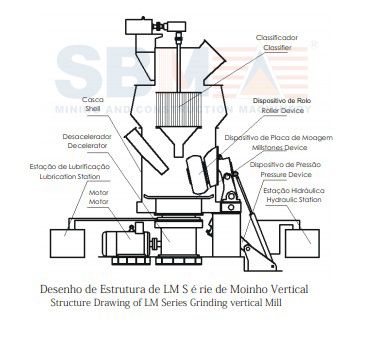

Vertical Roller Mill Introduction

Vertical Roller Mill is a new kind of large scale power mill which

is designed specially to solve the problems of low capacity and

high consumption of industry mills. With a decade of years’ research

of mills, Vertical Roller Mill is designed and manufactured based

on our advanced design idea, and in combination with the

European technology and the market demand. It adopts reliable

structure and reasonable process flow, integrated with drying ,

milling, classifier , elevator. Especially ,it can fully meets the

requirement of clients in the high production of powder and its

main technical and economy indicator reaches the international

level.

Application:

Specialized for the high production of superfine pyrophyllite

powder making in glass fiber industry

Specialized for the high production of gangue powder making

in coal industry

Specialized for the high production of various of chemical raw

material powder making in the chemical industry.

It is a necessary equipment for the high production of mineral

powder in the non-mental mine industry and large scale powder making in many

other industries.

Working principles of the Vertical Mill CLM:

The motor dives the grinding table to turn through the speed

reducer. At the same time, hot air comes into the roller mill

from the air inlet. The materials fall down the centre of grinding

table from the feeder. Because of the centrifugal force, the

materials move to the edge of grinding table from the centre .

The materials are crushed by the grinding roller when by pass

of the groove on the grinding table. The crusher materials

continue to move to the edge of the grinding table until taken

away by the airstream. Then the bigger materials fall down the

grinding table and the process of crushing continues. When

the materials in the airstream pass the separator on the top

of the mill, the materials fall down the grinding table from the

taper filler under the force of guide leaf blade. The fine powder

comes out with the airstream, and is gathered by the dust

catcher of the system. The powder gathered is the final product

of roller mill. In the process of the contact of airstream , the

materials are dried to meet the clients’ need at the proper moisture.

Through the adjustment of the angle between the separator and

the leaf of wind’s direction (not suitable to the small type of vertical

mill), and also the speed of the separator rotor, it can reach the

proper fineness of the materials.

|

Model |

LM |

LM |

LM |

LM |

LM |

LM |

|

|

Turnplate diameter (mm) |

***0 |

***0 |

***0 |

***0 |

***0 |

***0 |

|

|

Capacity (t/h) |

*0~*0 |

*3~*0 |

*8 |

*3~ |

*6~**4 |

*1~ |

|

|

Final product size |

μm |

**0~*5 |

**0~*5 |

**0 |

**0~ |

**0~*5 |

**0~ |

|

mesh |

*0~**5 |

*0~**5 |

|||||

| 国家: | China |

| 型号: | LM Series |

| 离岸价格: | 1 ~ 9999 / Set ( Negotiable ) 获取最新报价 |

| 位置: | Shanghai,China |

| 最小订单价格: | 1 per Set |

| 最小订单: | 1 Set |

| 包装细节: | Export Standard |

| 交货时间: | 30 Days |

| 供应能力: | 100 Set per Month |

| 付款方式: | L/C, T/T |

| 產品組 : | Grinding Mill & Equipments |