离岸价格

获取最新报价50000 ~ 200000 / Set ( Negotiable )

|1 Set Minimum Order

国家:

China

型号:

VT-350T

离岸价格:

50000 ~ 200000 / Set ( Negotiable ) 获取最新报价

位置:

-

最小订单价格:

50000 per Set

最小订单:

1 Set

包装细节:

Wood Packing + Film Cover

交货时间:

30-50 days

供应能力:

2 Set per Month

付款方式:

T/T, L/C

联系人 Yan

Dongguan, Guangdong

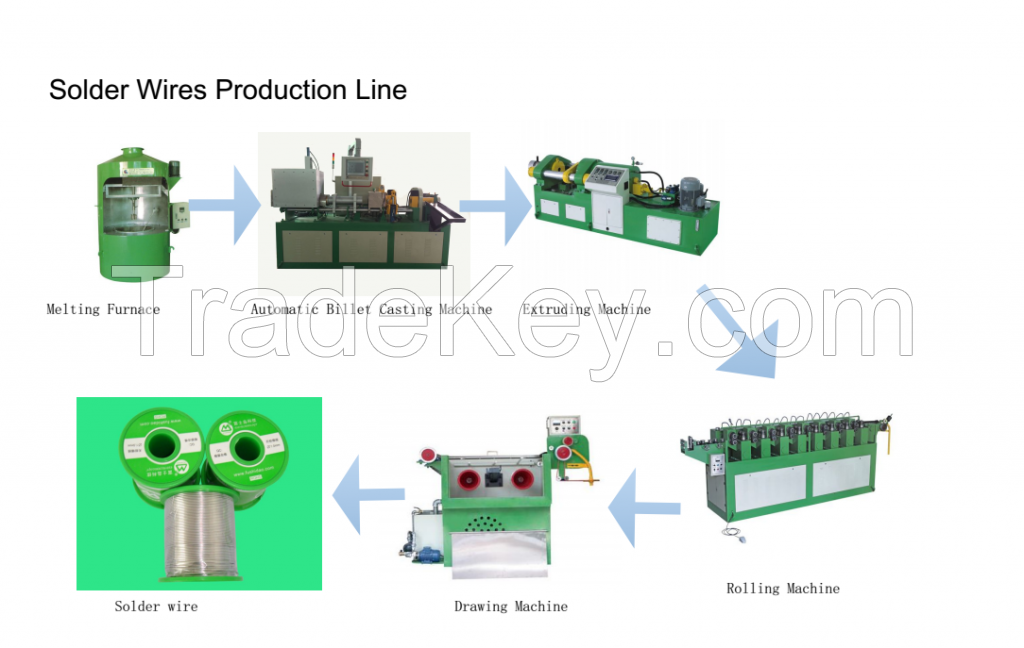

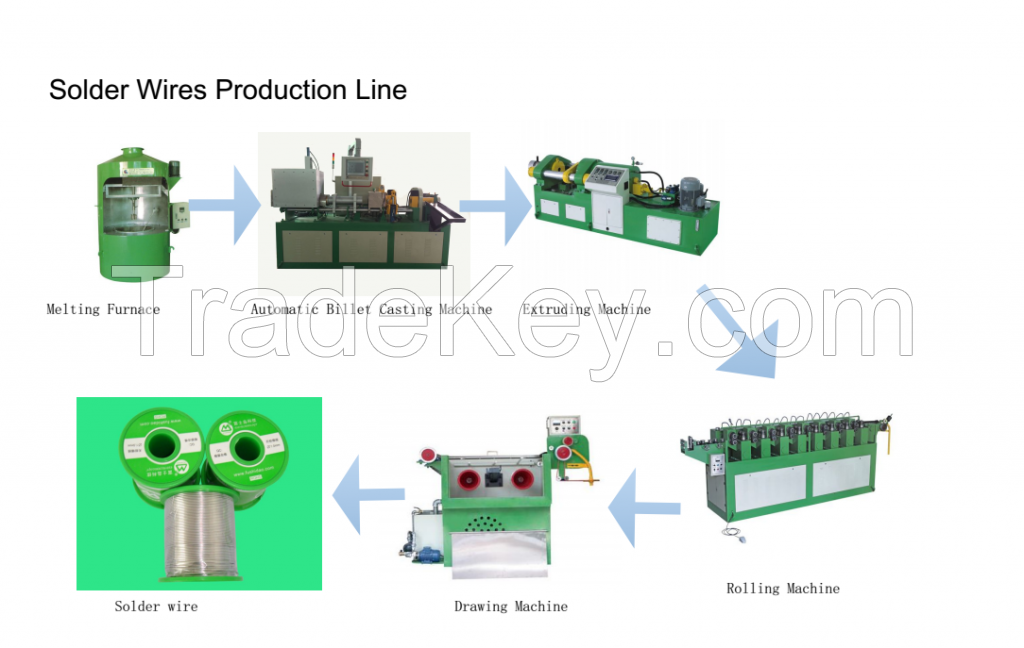

Electric heating Tin furnace(melting)

Device description:

Melt the outer layer of steel plate welded

structure, the inner tin pot with 304 stainless steel.

Exhaust hood is steel welding parts,

tin-pot fixed on the top side of a door, for investment casting

materials and other operations, the top has a smoke hole for

connecting smoke exhaust system.

1, stirrer

speed to achieve frequency control, speed adjustable, can meet

the technological requirements of different materials.

3, this

product has the furnace temperature responsive, energy saving,

easy operation and practical, safe and reliable.

This series

extruder is our self-developed products, using the number of

explicit conventional models, has obtained national patent

office issued a patent certificate, the model is mainly applied

to the tonnage of product types are:

(1) pewter wire (extrusion specifications

φ5-φ16mm)

b, can be extruded single and three

rosin core solder wire

a, Sn-Cu lead-free solder wire

c,

tin-silver-copper-lead-free solder lead-free solder tin and

zinc (Zn-containing not more than 25%)

(3) with lead-free solder

bar (must be configured to cut coder)

(1) Lead-Free Solder (extrusion grades

φ5-φ16mm)

b. tin-silver lead-free

solder wire

d. above solder can be

squeezed into a single and three other rosin core solder

wire

(2)

Lead anodes (anode rod cutting machine must be

configured)

1, using the ram cylinder (German technology), working

pressure error (0.002KG) with constant speed and stability

characteristics powerful hydraulic system to safeguard the

liquidity squeeze metals and rosin stability.

Third, the device

features:

2. Control

loop is DC24V, for persons and equipment more

secure.

This series of tin mill is our own research and

development, with the advanced technology of our products have

obtained national patent office issued a patent certificate,

the model is mainly applicable to rolling with lead solder and

lead-free solder wire production.

In the

body are arranged in parallel with a plurality of roller boxes,

each roll box with longitudinal and transverse two pairs of

rolls, the two pair of nip roll, respectively horizontal and

vertical distribution, the roll after rolling diameter is in

proportion to gradually become smaller , the compression ratio

is based on the characteristics of the design according to the

material extends, each second compression are of equal value,

when the wire through the rolls, the material roll is rotating

roll, pressure is small wire from the roll after the extrusion,

the final The traction device delivered to the closing of the

wire trays, achieving wire roll.

A

high production efficiency: the ability of large diameter line,

is generally not the water tank drawing machine.

3, the noise is low: the traditional

tank drawing machine wire drawing process in the tower wheel

slip, and wire EDM noise generated through the larger, and

during the rolling mill roll wire without jitter, slipping

through the rollers is small, the low noise.

5, the production of good quality wire rod: after

the sequence is not easy to break drawing, wire after rolling

through denser metal structure will improve

elongation.

Solder wire Drawing machine(Drawing)

The main part of the wire drawing machine was joint by steel plate steel, and driven by double chain, spray hard chrome on the roller to improve the rigidity and the roughness of the surface. Cool and lubricate the drawing part by steeping, with cover to prevent the cooling liquid splash out. Adopt 15KW motor with inverter control to ensure the stable speed.

Technical parameter

1, Inlet wire mm 5

3, Max speed m/min 220

5, Speed fix wheel diameter mm 160

7, Outer dimension mm(L*W*H) 2140x885x1100

8, Machine weight T 1

Input Lubricating oil and arrange drawing die before down lead, and then draw the wire through the dies according to the tightness of each dies and machine work condition. Make two circles around the roller for the strong pull, one circle for weak pull; (Generally, big diameter wire needs strong pull while small diameter wire needs weak pull. The operator can judge according to the operation.) Finally, put the wire through the wire press wheel and out-let pipeline, then ready to draw the wire.

Operation precautions

1) Keep the lubricant temperature lower than 50°C, or it will affect the heat giving out.

2) Electrical connections must be properly grounded

3) Lubricant all the running parts every two weeks.

4) If theres badly shaking or swing of the roller, please check the fixing nut of the roller to ensure it does no damage to the machine by friction between the roller & axis.

5) If theres any decrease of the power or slipping, disassembly the back cover to check whether the belt is tight enough and screw the fixing nut tight to adjust the belt.

6) If theres exceptional noise during the running, open the cover and check whether theres shift in the drive chain wheel and screw tight the fixing nut.

7) Cleaning the dies every shift with diesel oil or kerosene.

Maintenance

Automatic wire Winding machine(Winding)

1.Technical parameters:

VT-06A belongs tin line-up machine for automatic

admission wound type, mainly used for leaded and lead-free

solder wire packaging, is obtained by a good wire drawing

machine drawing close around the spool, the completion of the

final product processes. The machine

nice shape, low noise, simple operation, cable tidy, materials

for smaller diameter than the semi-automatic winding-up machine

better.

VT-06A belongs tin line-up machine for automatic

admission wound type, mainly used for leaded and lead-free

solder wire packaging, is obtained by a good wire drawing

machine drawing close around the spool, the completion of the

final product processes. The machine

nice shape, low noise, simple operation, cable tidy, materials

for smaller diameter than the semi-automatic winding-up machine

better.

| 国家: | China |

| 型号: | VT-350T |

| 离岸价格: | 50000 ~ 200000 / Set ( Negotiable ) 获取最新报价 |

| 位置: | - |

| 最小订单价格: | 50000 per Set |

| 最小订单: | 1 Set |

| 包装细节: | Wood Packing + Film Cover |

| 交货时间: | 30-50 days |

| 供应能力: | 2 Set per Month |

| 付款方式: | T/T, L/C |

| 產品組 : | Solder Products Making Machines |