-X-ray equipment

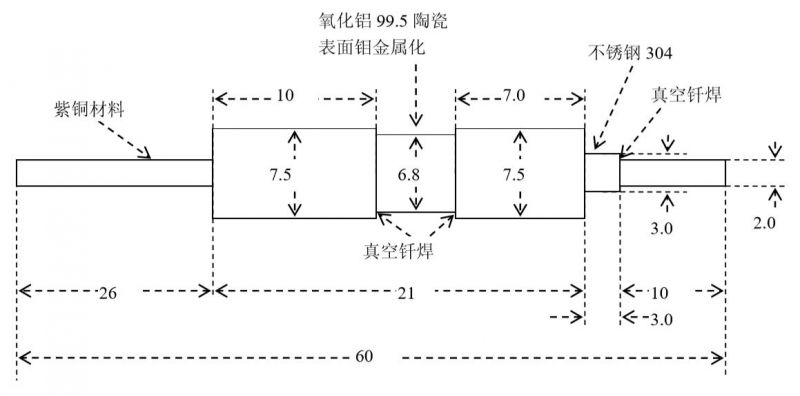

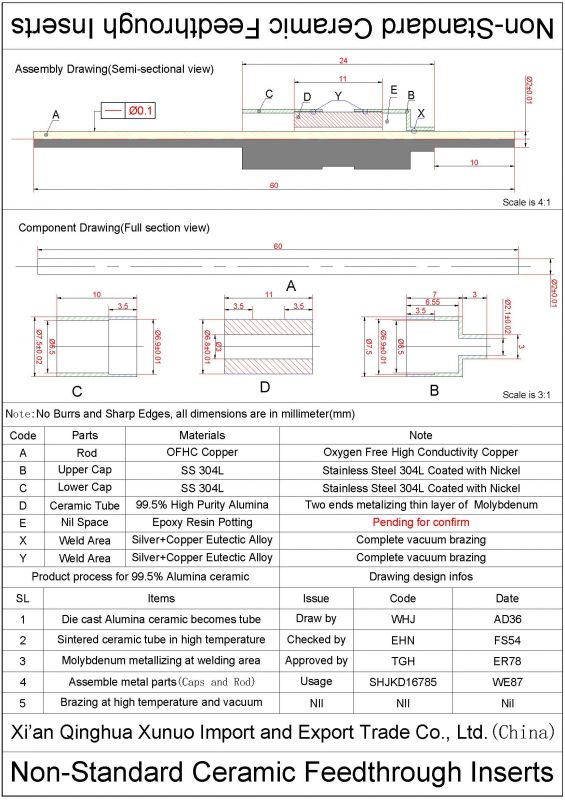

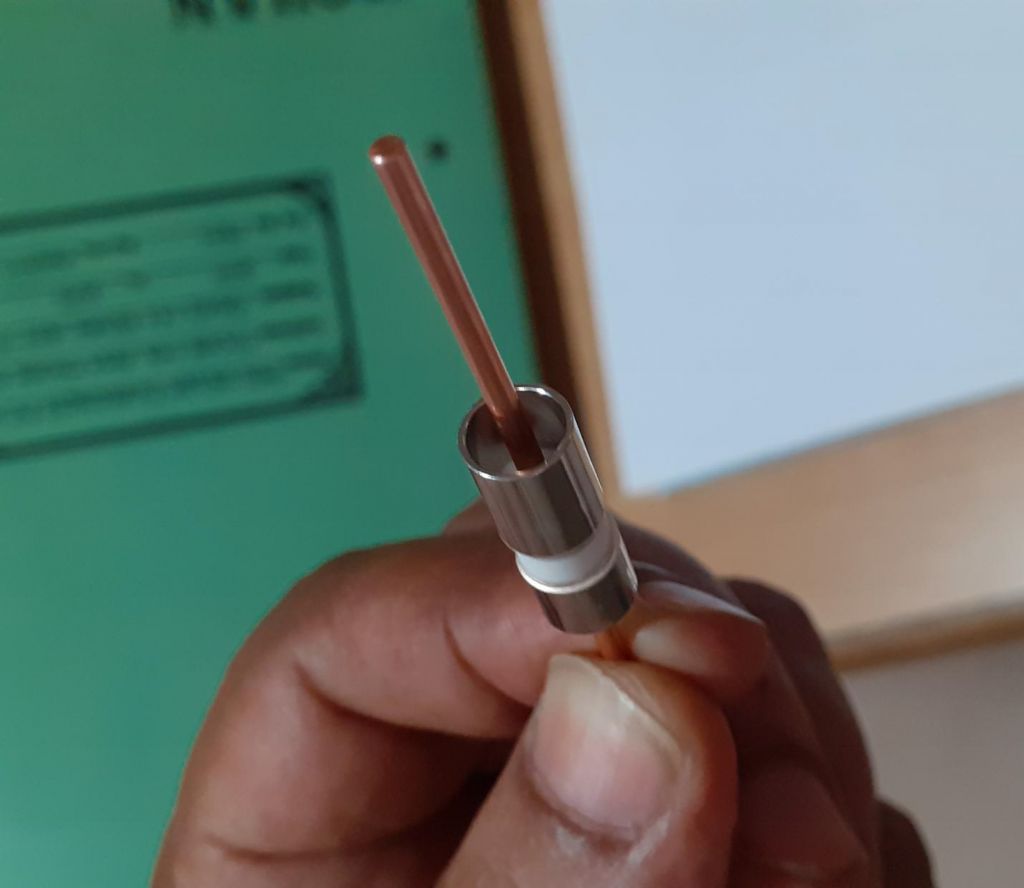

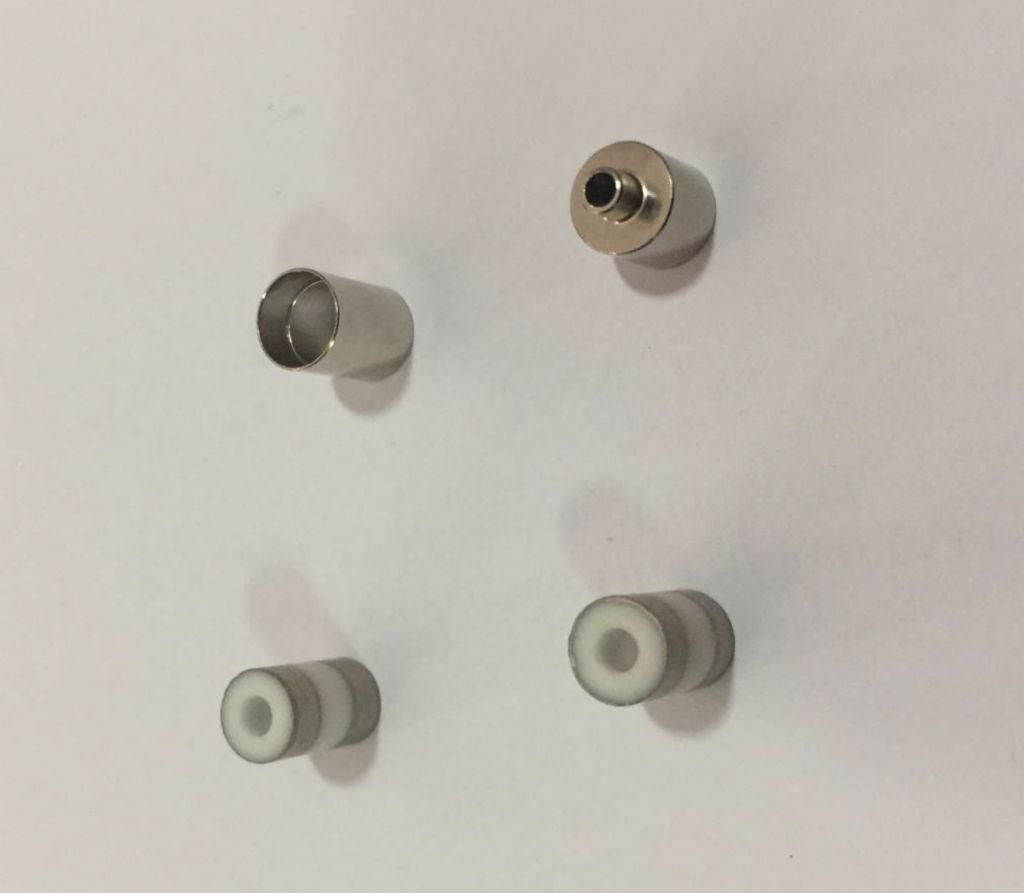

Typical Construction of QHXN Vacuum

Ceramic Feedthrough Insert

(1) Conductor,

(2) Washer,

(3) Cap,

(4) Insulator,

(5) Sleeve,

(6) Weld Adapter

QHXN ceramic-to-metal feedthroughs use only inorganic

materials. The insulators are made from high-purity,

high-strength, low-loss alumina ceramics. Metals include

stainless steel, nickel, copper, nickel-iron alloys,

cupro-nickel alloys, molybdenum. In designs, standard

design practices consider electrical characteristics such

as flashover, corona breakdown, creep, dielectric strength

and puncture resistance.

Braze materials used are silver, copper, silver-copper or

gold-copper alloys. Metalization processes include both

refractory-metal and active-metal metalizations, depending

on the size, geometry and performance requirements for the

feedthrough. QHXN uses advanced techniques and methods to

control and monitor critical processes, including 100

percent helium leak testing and x-ray measurements for

metalization control.

Standard installation mountings for QHXN ceramic-to-metal

feedthroughs include:

-Brazing

-Welding (pulse-TIG, TIG, laser, E-beam welding)

-ISO KF flange

-ConFlat flange

-NPT fitting

-1" baseplate

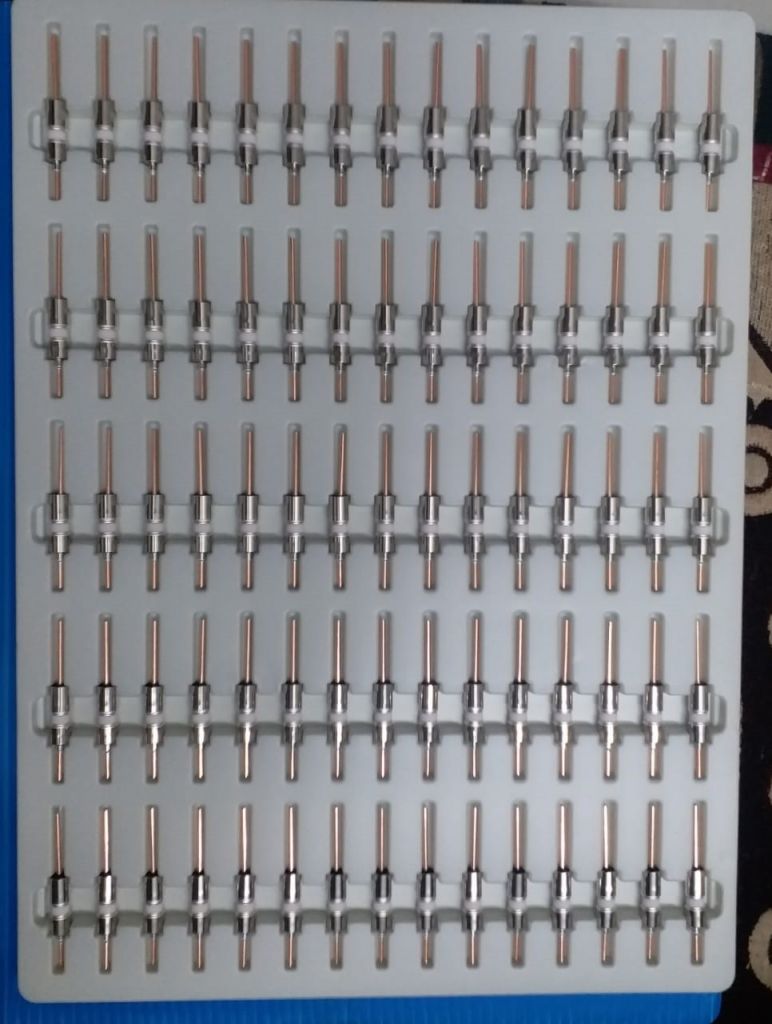

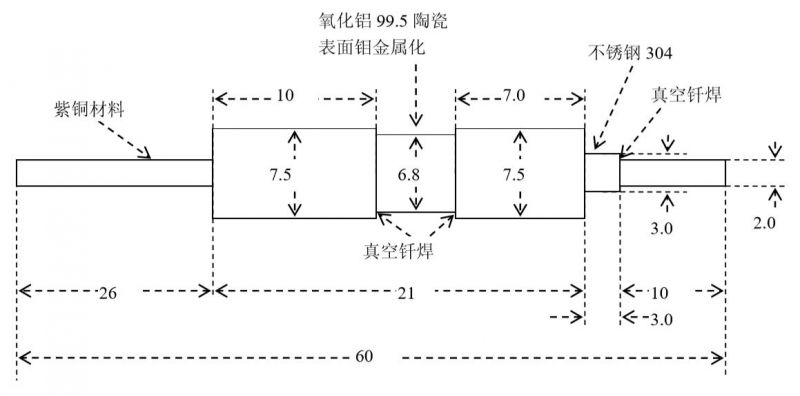

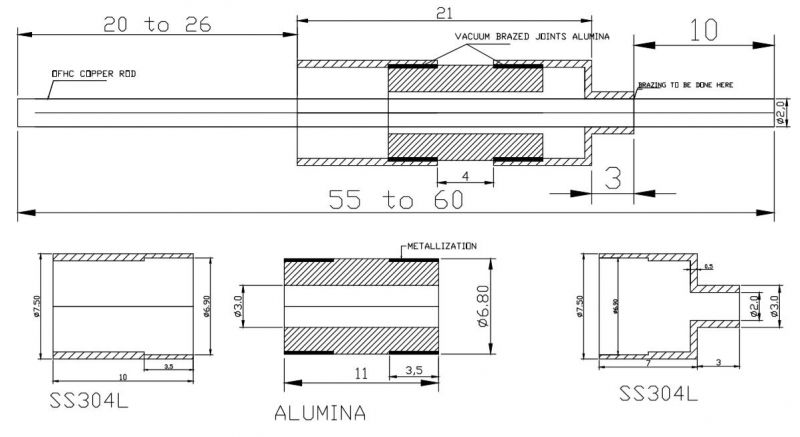

1) ceramic tube 97% to 99% high purity alumina and two

ends metalizion thin layer of a molybdenum

2) two end SS307L metal caps

3) OHFC copper rod dia 2 mm

Final feed through will be achieved- Test for final

dielectic strength :2.5K V.

Insulation resistance test will be achieved (1000 V

DC,1 Gigaohm)

leak test - Vacuum leak acceptance range better

than 1X10 -9 mbar-lit/sec of helium MSLD

Required property of ceramic tubes: The ceramic tube

shall conform to the electrical,mechanical,thermal and

general property requirements specified as follows.

Non-Standard

Vacuum Ceramic Feedthrough Insert

Non-Standard

Vacuum Ceramic Feedthrough Insert