详情

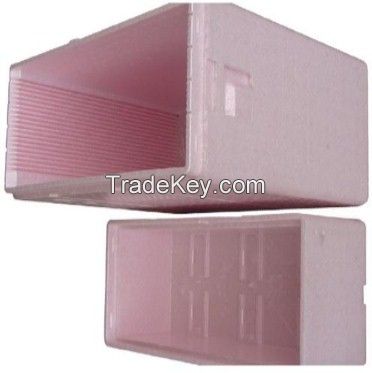

EPP is suitable for reusable packaging and reusable transport

containers.

Compared to other foam materials, EPP is especially suitable for

reusable packaging and reusable transport containers. Its high

resilience after static, dynamic stressing, good chemical

resistance, as well as its excellent cushioning performance at

extremely low weight make EPP ideal for these applications.

Applications include in-plant transportation containers for

automobile mirrors, brake calipers or steering gears. Depending on

the level of stress, the containers can typically sustain **0 or

more transport cycles. As a result, EPP helps economize on

packaging materials, thereby resulting in lower costs for our

customers. Due to its high thermal stability, moldings made of EPP

can be sterilized, representing a particular advantage for medical

applications and food containers.

Electrically conductive EPP materials are available for packaging

sensitive electronic goods. Tailored to meet current market

requirements and standards, moldings can be produced with different

levels of conductivity. The manufacturing process ensures that

conductivity is achieved and maintained throughout the entire

lifetime of a molding, a particular benefit for reusable packaging

or in-plant transportation containers.

With disposable packaging, there is no need to use protective film

for sensitive electronic goods. These properties are preserved even

under changing climate conditions (i.e. humidity and heat).