详情

Brief introduction:

The ball mill is a key equipment to grind the crushed materials,

and the ball mill is widely used in powder-making production line

including cement, silicate, new-type building material,

refractory material, fertilizer, ore dressing of ferrous metal

and non-ferrous metal, glass ceramics, etc, with medium hardness.

They are manufactured with highest quality material and

workmanship; deliver the most efficient, trouble free and

economical combination of material ranging from (***0mm) down to

varying product sizes.

According to the different milling ways, the ball mills can be

divided into dry and wet types. Due to the ways of discharge are

different, there are two types of ball mills: into-lattice type

and over-flow type, or center-discharging type and

side-discharging type. In accordance with the different kinds of

support, they can be split into two types: bearing mill and

bushing mill. According to the different kinds of transmission,

edge type and center type are available. Besides, the type of

over-flow ball mills are normally used for most ball mill

grinding applications and provide the most simple, trouble-free

and economical method of grinding. Mills are available with

spiral-screen, configured for discharge trunnion, to provide

material sizing and classification.

Application:

Ball mill are generally used to grind material 1/4 inch and

finer, down to the particle size of *0 to *5 microns. To achieve

a reasonable efficiency with ball mills, they must be operated in

a closed system, with oversize material continuously being

recirculated back into the mill to be reduced. Various

classifiers, such as screens, spiral classifiers, cyclones and

air classifiers are used for classifying the discharge from ball

mills. Ball mill is an efficient tool for grinding many materials

into fine powder. The ball mill is used to grind many kinds of

mine and other materials, or to select the mine. It is widely

used in building material, chemical industry, etc. There are two

ways of grinding: the dry process and the wet process. It can be

divided into tabular type and flowing type according to different

forms of discharging material.

Features:

1) It is an efficient tool for grinding many materials into fine

powder.

2) The ball mill is used to grind many kinds of mine and other

materials, or to select the mine

3) Ball mill is widely used in building material, and chemical

industry.

4) There are two ways of grinding: the dry way and the wet

way.

5) Ball mill can be divided into tabular type and flowing type

according to different expelling mine

6) To use the ball mill, the material to be ground is loaded into

the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the

individual pieces of grinding media that mix and crush the

product into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will

be.

9) Ultimate particle size depends entirely on how hard the

material you're grinding is, and the time how long the ball mill

runs.

*0) Our ball mills have been used to grind glass, powder food

products, create custom varnishes, make ceramic glaze, powder

various chemicals.

*1) Completely enclosed welded design in high-grade steel.

- Direct drive via bearing journal with top-mounted gearbox.

- Motor connected to gearbox via a V-belt drive.

- Product discharge via slots located around the periphery of the

drum.

Working Principles:

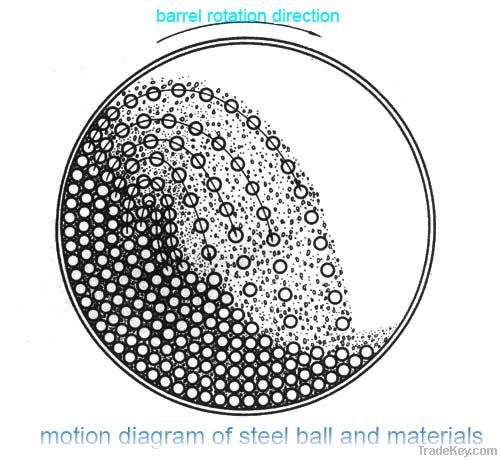

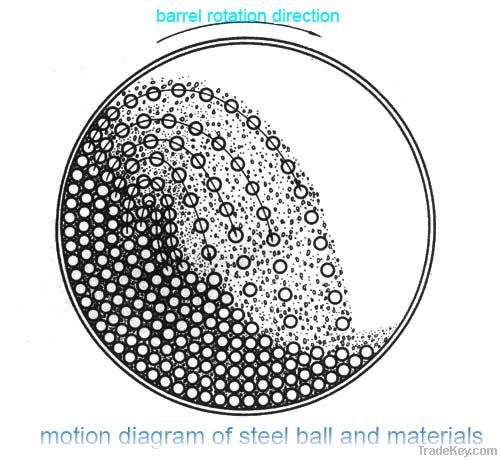

The ball mill is a horizontal rotating device transmitted

by the outer gear. The materials are transferred to the grinding

chamber through the quill shaft uniformly. There are ladder liner

and ripple liner and different specifications of steel balls in

the chamber. The centrifugal force caused by rotation of barrel

brings the steel balls to a certain height and impact and grind

the materials. The ground materials are discharged through the

discharging board thus the grinding process is finished.

More detailed information is in our website.

| 国家: |

China |

| 型号: |

MQYG

|

| 离岸价格: |

(面議)

获取最新报价

|

| 位置: |

Zhengzhou |

| 最小订单价格: |

- |

| 最小订单: |

- |

| 包装细节: |

no |

| 交货时间: |

negotiable |

| 供应能力: |

- |

| 付款方式: |

T/T, L/C, D/A, D/P, Western Union |

| 產品組 : |

grinding machine

|