离岸价格

获取最新报价|

- Minimum Order

国家:

China

型号:

-

离岸价格:

位置:

-

最小订单价格:

-

最小订单:

-

包装细节:

-

交货时间:

-

供应能力:

-

付款方式:

-

產品組 :

联系人 Ms. Tina

fengxian, Shanghai, Shanghai

——AUTOMATICSTEELCOIL WRAPPING MACHINE

I.MACHINEAPPLICATION:

Thisautomatic steelcoil wrapping machine adopts vertical packing

position. It is a set of integrated multi-station wrapping machine

specially designed for wrapping steel coils with a

bigsize, to make theobject waterproof, rustproof, dustproof, well

protectedfrom

friction,andconvenient for

transportation.

II.

INSTALLATION:

Place the machine on the flat

ground surface.

III.

BASIC FEATURES:

| Main part | Brand |

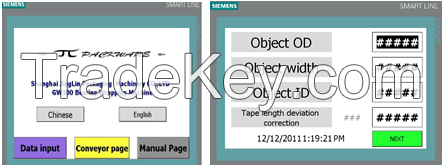

| PLC | Siemens |

| HMI | Siemens |

| Converter | Siemens |

| Sensor | Autonics |

| Encoder | Delta |

| Bearings | HRB |

| Cylinder&pneumatic components | Airtec |

| , ,,Main motors | Tunglee |

| switch、、Contactor | Schneider |

| Item | Quantity |

| Main engine of the machine with guide rail | 1 set |

| U-type Orbital | 1 set |

| Electrical cabinet, guardrail etc. | 1 set |

| Film release shuttle | 1set |

| Roller station | 1 set |

| Spare parts and user manual | 1 set for each |

| PLC&HMI control system | 1 set for each |

| 国家: | China |

| 型号: | - |

| 离岸价格: | 获取最新报价 |

| 位置: | - |

| 最小订单价格: | - |

| 最小订单: | - |

| 包装细节: | - |

| 交货时间: | - |

| 供应能力: | - |

| 付款方式: | - |

| 產品組 : | Wire coil cable products |